A kind of medium-high temperature hard rubber recyclable foam drilling fluid and preparation method thereof

A drilling fluid, medium and high temperature technology, applied in chemical instruments and methods, drilling compositions, geothermal energy power generation, etc., can solve the problems of waste of treatment agent cost, less cycle times, insufficient temperature resistance, etc., to protect oil and gas layer, low solid content, saving preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Take 100 parts of clean water, add 0.1 part of low molecular weight anti-high temperature foam stabilizer TFS to it, stir with a low-speed agitator for 2 hours; add 0.2 part of alkylphenol polyoxyethylene ether after uniform dispersion and dissolution, and fully stir for 15min; add modified hard 1.5 parts of husk plant fiber powder, fully stirred for 5 minutes, and left to stand for 2 hours to form a temperature-resistant hard gum base liquid. Accurately weigh 0.2 part of xanthan gum, 0.5 part of sulfonate polymer fluid loss reducer, 0.2 part of sodium dodecylbenzenesulfonate, 0.1 part of sodium dodecyl sulfate, 2 parts of lignite resin and 1 part of phenolic resin Mix evenly, add the above temperature-resistant hard rubber base fluid while stirring, and stir with a low-speed strong mixer at 900 r / min for 6 hours to form a high-temperature hard rubber recyclable micro-foam drilling fluid or completion fluid.

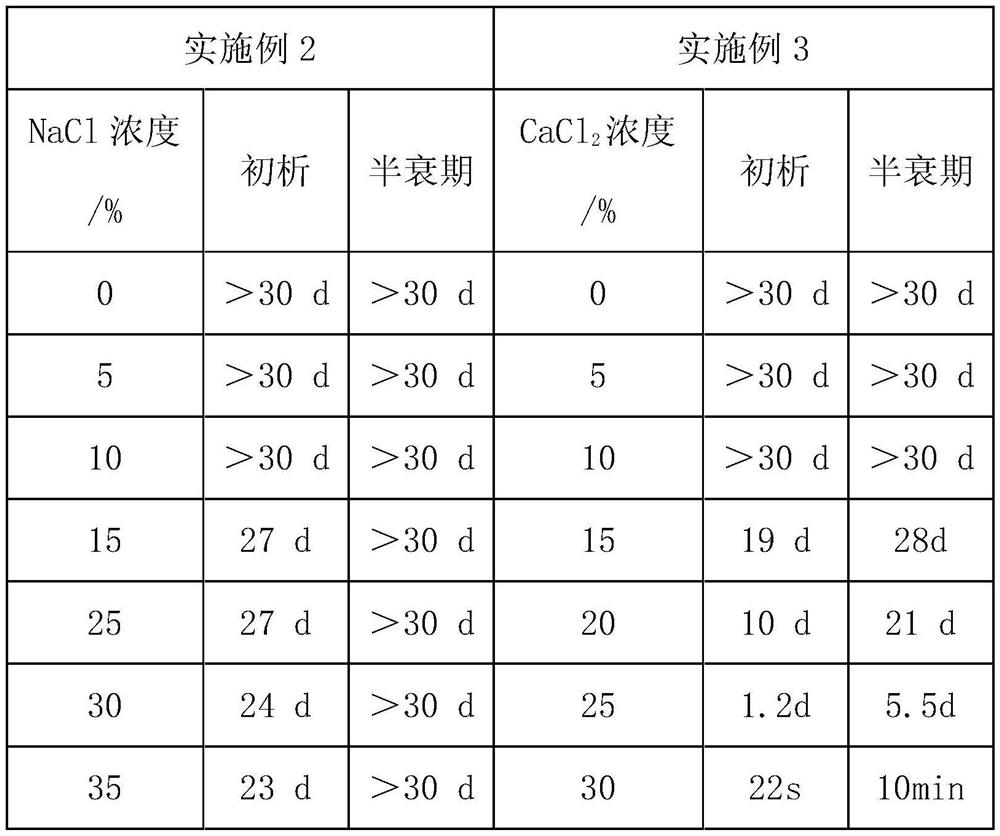

Embodiment 2

[0074] Take 100 parts of clean water, add 0.2 part of low molecular weight anti-high temperature foam stabilizer TFS to it, stir with a low-speed mixer for 2 hours; after uniform dispersion and dissolution, add 0.2 part of polysorbate respectively, stir well for 15 minutes; add modified hard shell 1.5 parts of plant fiber powder, fully stirred for 5 minutes, and allowed to stand for 2 hours to form a temperature-resistant hard gum base liquid. Accurately weigh 2 parts of sodium bentonite, 0.08 part of sodium carbonate, 0.1 part of hydroxyethyl cellulose, 0.1 part of xanthan gum, 0.3 part of sodium sulfonate polymer fluid loss reducer, 0.2 part of sodium dodecylbenzenesulfonate, 0.1 part of sodium lauryl sulfate, 2 parts of potassium humate fluid loss reducer, and 1 part of sulfonated phenolic resin fluid loss reducer are mixed evenly, and the above temperature-resistant hard gum base liquid is added while stirring. / min stirring for 6h to form medium and high temperature hard ...

Embodiment 3

[0076] Take 100 parts of clean water, add 0.2 part of low molecular weight anti-high temperature foam stabilizer TFS to it, stir with a low-speed mixer for 2 hours; after uniform dispersion and dissolution, add 0.1 part of alkylphenol polyoxyethylene ether and 0.1 part of polysorbate respectively. , fully stirred for 15min; added 2 parts of modified hard-shell plant fiber powder, fully stirred for 10min, and stood for 2h to form a temperature-resistant hard glue base liquid. Accurately weigh 3 parts of sodium bentonite, 0.1 part of sodium carbonate, 0.1 part of xanthan gum, 0.3 part of sulfonate polymer fluid loss reducer, 0.2 part of sodium dodecylbenzenesulfonate, 0.1 part of sodium dodecyl sulfate , 2 parts of lignite resin and 1 part of phenolic resin, mix them evenly, add the above temperature-resistant hard rubber base liquid while stirring, and stir with a low-speed strong mixer at 1000 r / min for 6 hours to form a medium-high temperature hard rubber recyclable micro-foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com