High-impact-resistance glass fiber reinforced polypropylene material and manufacturing process thereof

A polypropylene material and manufacturing process technology, applied in the field of polymer modified materials, can solve the problems of high cost and poor anti-falling effect, and achieve the effects of improving rigidity, good dimensional stability and good low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

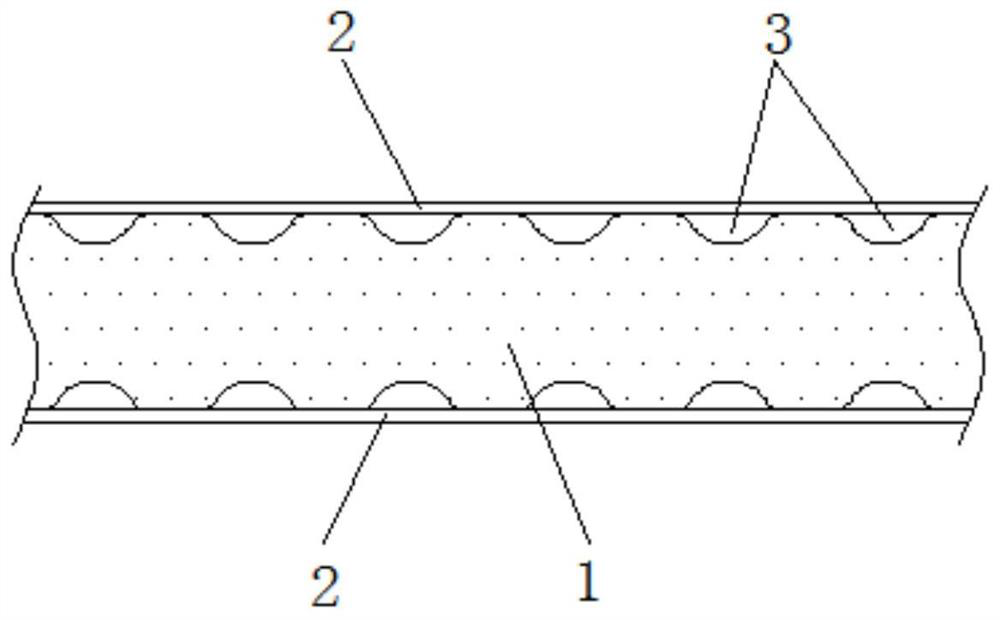

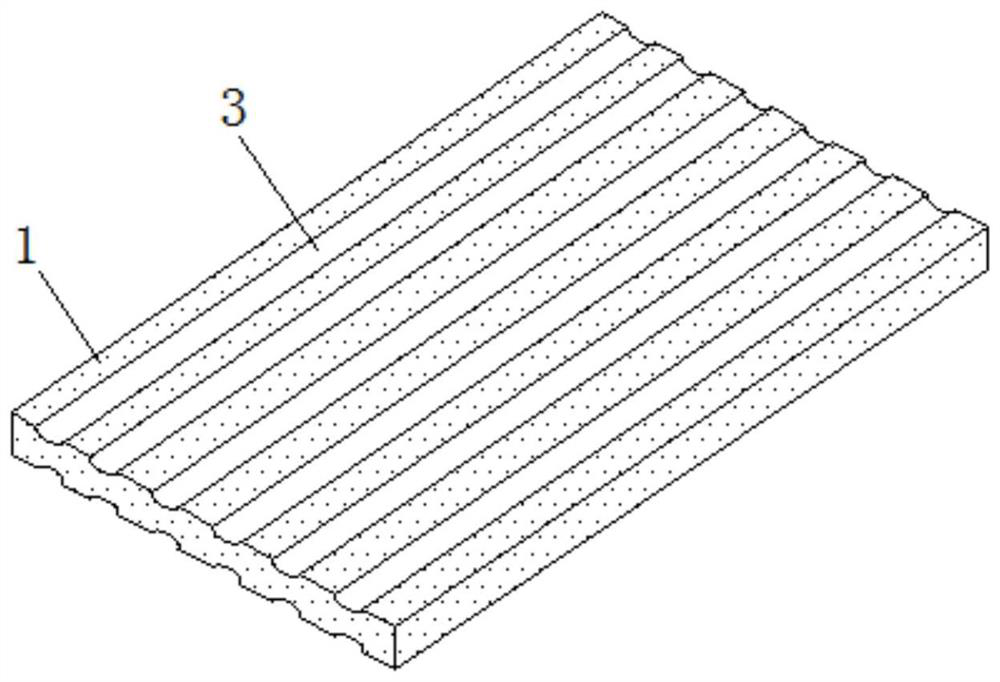

[0029] A glass fiber reinforced polypropylene material with strong impact resistance in this embodiment includes a modified PP material in the middle body part and a glass fiber mesh cloth glued to the upper and lower sides thereof, and the modified PP material 1 is composed of the following components : 5 parts of polypropylene raw material, 4 parts of glass fiber powder, 0.7 part of butadiene rubber, 0.01 part of nucleating agent, 0.01 part of coupling agent and 0.28 part of toughening agent.

[0030] The modified PP material in this example is made according to the following steps: mix the raw materials according to the ratio of the example and add them to the conical mixer, and stir for 20 minutes at a speed of 350 rpm; add the stirred material into the screw extruder for heating Melt and extrude, granulate, the temperature ranges of the front end, middle end and rear end of the extrusion cavity are 195°C, 205°C and 225°C respectively, and the extrusion pressure is 1.0MPa; ...

Embodiment 2

[0035] A glass fiber reinforced polypropylene material with strong impact resistance in this embodiment includes a modified PP material in the middle body part and a glass fiber mesh cloth glued to the upper and lower sides thereof, and the modified PP material 1 is composed of the following components : 5 parts of polypropylene raw material, 4 parts of glass fiber powder, 0.7 part of butadiene rubber, 0.01 part of nucleating agent, 0.02 part of coupling agent and 0.27 part of toughening agent.

[0036] The modified PP material in this example is made according to the following steps: mix the raw materials according to the ratio of the example and add them to the conical mixer, and stir for 20 minutes at a speed of 350 rpm; add the stirred material into the screw extruder for heating Melt and extrude, granulate, the temperature ranges of the front end, middle end and rear end of the extrusion cavity are 195°C, 205°C and 225°C respectively, and the extrusion pressure is 1.1MPa; ...

Embodiment 3

[0041] A glass fiber reinforced polypropylene material with strong impact resistance in this embodiment includes a modified PP material in the middle body part and a glass fiber mesh cloth glued to the upper and lower sides thereof, and the modified PP material 1 is composed of the following components : 5 parts of polypropylene raw material, 4 parts of glass fiber powder, 0.7 part of butadiene rubber, 0.01 part of nucleating agent, 0.01 part of coupling agent and 0.28 part of toughening agent.

[0042]The modified PP material in this example is made according to the following steps: mix the raw materials according to the ratio of the example and add them to the conical mixer, and stir for 20 minutes at a speed of 350 rpm; add the stirred material into the screw extruder for heating Melt and extrude, granulate, the temperature ranges of the front end, middle end and rear end of the extrusion cavity are 195°C, 205°C and 225°C respectively, and the extrusion pressure is 1.2MPa; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com