Covalent bond type silicon-titanium flocculant as well as preparation method and application thereof

A covalent bond and flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water pollutants, etc., can solve the problems of being easily affected by temperature and water quality fluctuations, low removal rates of nitrogen, phosphorus and DOC, Problems such as large amount of use, to achieve the effect of good product reproducibility, good effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

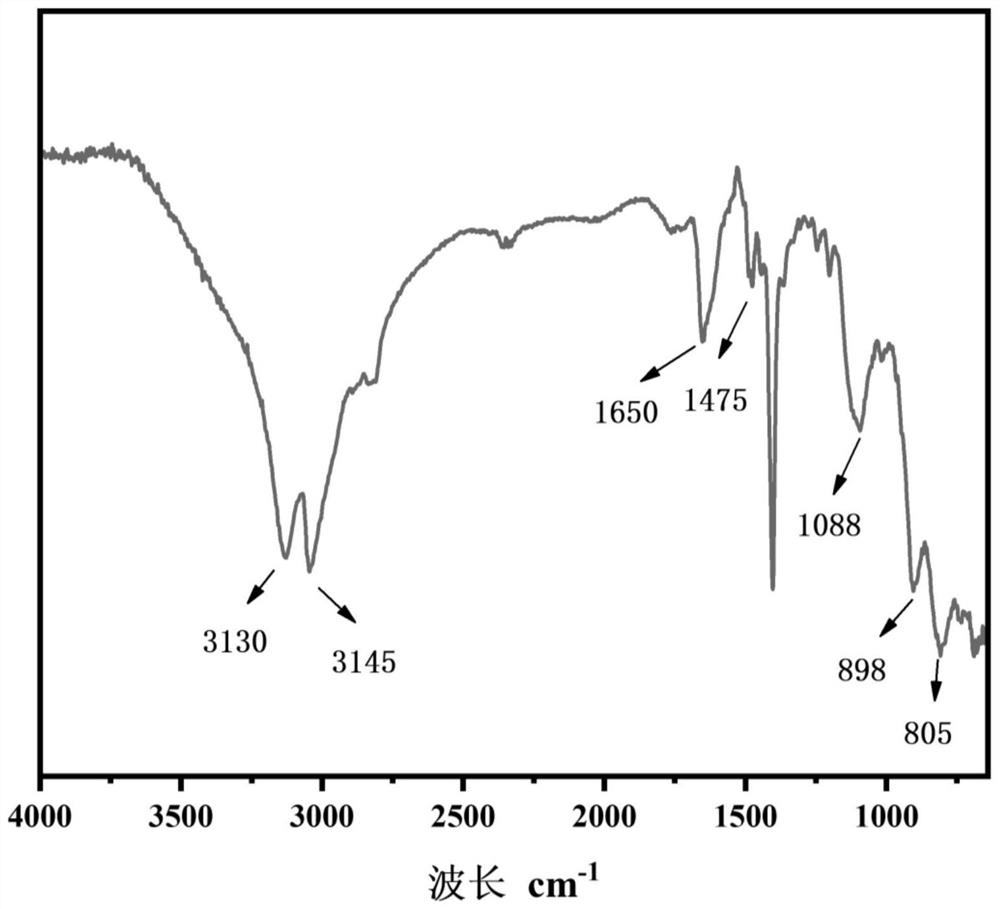

Image

Examples

preparation Embodiment 1

[0026] According to the Si / Ti molar ratio of 0.05, take 100.0 mL of Ti(SO 4 ) 2 Solution, 0.00125mol trimethyl([3-(triethoxysilyl)propyl]ammonium chloride), 12.5mL deionized water were put into a three-necked flask, stirred and mixed evenly at room temperature. Then, stir at 500r / min for 4h at room temperature, and slowly add 12.5mL of NaHCO with a concentration of 1mol / L dropwise. 3 Solution to alkalization degree B is 0.5. The obtained solution was allowed to stand and mature for 48 hours until the reaction was complete, and a flocculant with a total titanium concentration of 0.2 mol / L was obtained.

preparation Embodiment 2

[0028] According to the Si / Ti molar ratio of 0.1, take 25.0 mL of TiCl with a concentration of 1.0 mol / L 4 Solution, 0.0025mol γ-aminopropyltriethoxysilane, and 75.0mL deionized water were put into a three-necked flask, and stirred and mixed evenly at room temperature. Then stir rapidly at room temperature, and slowly add 25.0 mL of NaOH solution with a concentration of 0.5 mol / L dropwise until the degree of alkalinity B is 0.5. The obtained solution was allowed to stand and mature for 24 hours, and after the reaction was complete, a flocculant with a total titanium concentration of 0.2 mol / L was obtained.

preparation Embodiment 3

[0030] According to Si / Ti molar ratio is 0.2, take 50.0mL Ti(SO 4 ) 2 Solution, 0.005mol trimethyl([3-(triethoxysilyl)propyl]ammonium chloride), 75.0mL deionized water were put into a three-necked flask, stirred and mixed evenly at room temperature, and the obtained solution was allowed to stand and mature for 24 hours. After the reaction is complete, a flocculant with a degree of alkalinity B of 0 and a total titanium concentration of 0.2 mol / L is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com