Automatic logistics transportation, sorting, loading and unloading system and loading and unloading method

An automatic transportation, loading and unloading system technology, applied in the field of aviation logistics, can solve the problem of high error rate of cargo grabbing and palletizing, and achieve the effect of highly automated sorting and palletizing and convenient grabbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

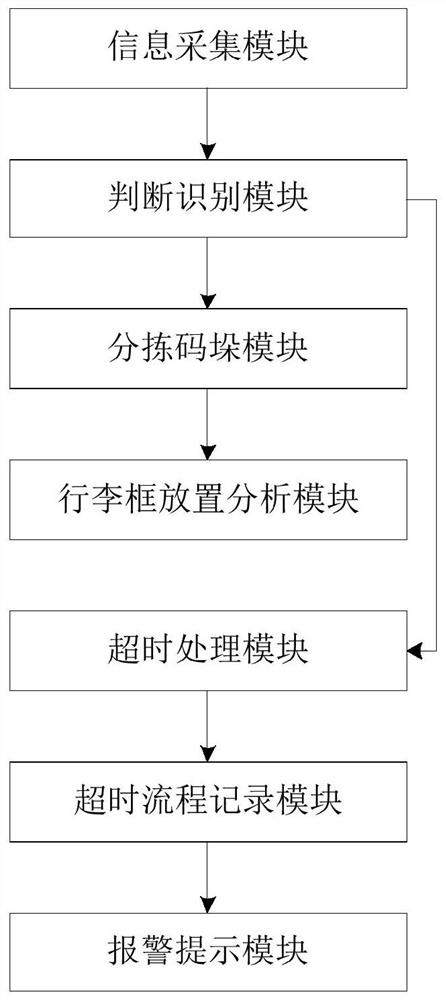

[0047] A logistics automatic transportation, sorting, loading and unloading system, basically as attached figure 1 Shown: including palletizing robot, luggage box, conveyor belt, transfer device and server; When arriving at the luggage box, grab the luggage box on the conveyor belt and put it on the transfer device, so as to realize sorting and palletizing. The luggage box is used to store checked luggage and can be freely adjusted in size. The conveyor belt is used to convey the luggage boxes, which is convenient for the palletizing robot to grab, sort and palletize. The server is used to communicate with the palletizing robot and the conveyor belt to realize the collection, processing and output of control information in the process of automatic logistics transportation, sorting, loading and unloading. The conveyor belt includes a conveyor belt body, a motor, a motor controller and a support frame, and the motor controller is connected to the server by communication.

[0...

Embodiment 2

[0071] The difference between the second embodiment and the first embodiment is that the structure of the luggage frame is as follows:

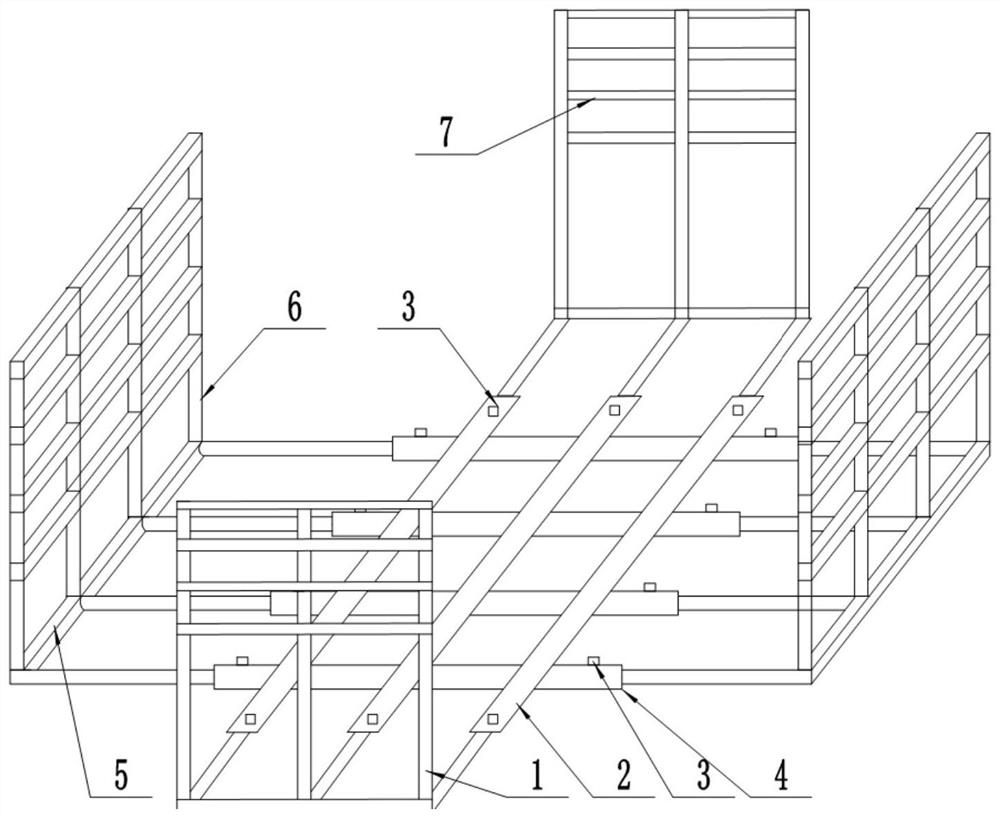

[0072] Such as figure 2 As shown, the luggage frame includes several parallel and spaced horizontal telescopic rods 4 and several vertical telescopic rods 2 arranged horizontally and perpendicularly to the horizontal telescopic rods 4, and the free ends of the horizontal telescopic rods 4 are vertically fixed with a second A connecting rod 6, the second connecting rod 1 is vertically fixed on the end of the longitudinal telescopic rod 2, and the first connecting rod 6 and the second connecting rod 1 are both provided with electronic tags.

[0073] The horizontal telescopic rod 4 includes a first fixed portion and a first telescopic portion, the first fixed portion and the first telescopic portion are slidably connected, and the first connecting rod 6 is vertically fixed at the end of the first telescopic portion; The longitudinal telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com