Digital die cutting material part, digital die cutting machine and working control method of digital die cutting machine

A work control, die-cutting machine technology, applied in the direction of copy/marking method, typewriter, metal processing, etc., can solve the problems of easy deviation of the die-cutting path, difficult identification of marking points, and increase the occurrence rate of defective products. Operation and promotion, to ensure effective identification, and the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

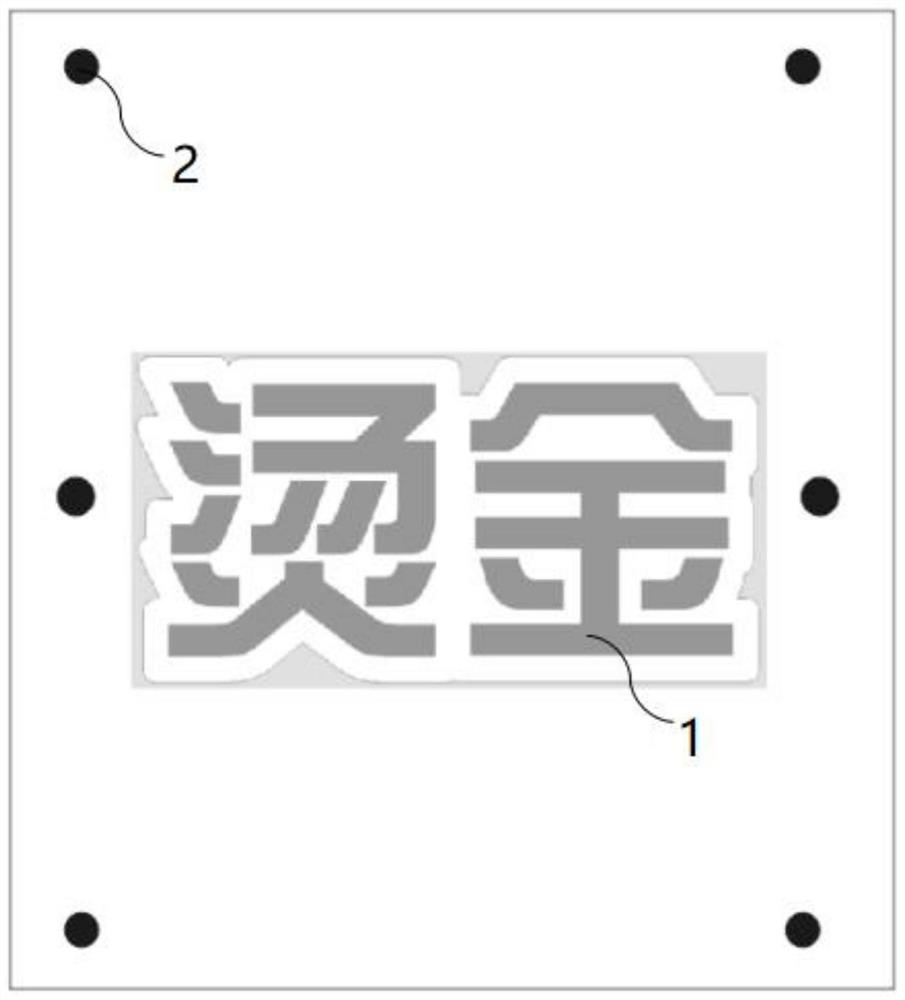

[0059] Such as figure 1 As shown, the material is white paper, and the pattern 1 and marking point 2 on the printing carrier are printed by a laser printer. The color of pattern 1 is black, and the shape of marking point 2 is circular with a diameter of 6mm. The color is preferably yellow, One of red, green, blue, orange, purple.

Embodiment 2

[0061] Such as figure 1 As shown, the pattern 1 and marking point 2 are printed on the self-adhesive in color, the background color of the self-adhesive is white, the color of pattern 1 is black and contains black toner, and the shape of the marking point 2 is a circle with a diameter of is 6mm, and the color is yellow; since bronzing only works with black toner, when this self-adhesive material is in the bronzing process, the top of the pattern 1 is bronzed, but the marking point 2 is not bronzed; the bronzing When the material is cut with a die-cutting machine, the die-cutting machine can accurately identify the marking point 2 that has not been stamped, so as to achieve accurate alignment of the cutting position, and the scrap rate of the cut finished product is low, which reduces the production cost.

[0062] The second digital die-cutting material

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com