Square and flat steel cold rolling and drawing integrated equipment

A square flat steel, integrated technology, applied in metal processing equipment, forming tools, feeding devices, etc., can solve problems such as difficulty in accelerating the liquid flow of cold-rolled pickling tanks, inability to improve pickling efficiency of steel, and limited pressing range of pressing plates , to achieve the effects of easy operation, improved drawing efficiency and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

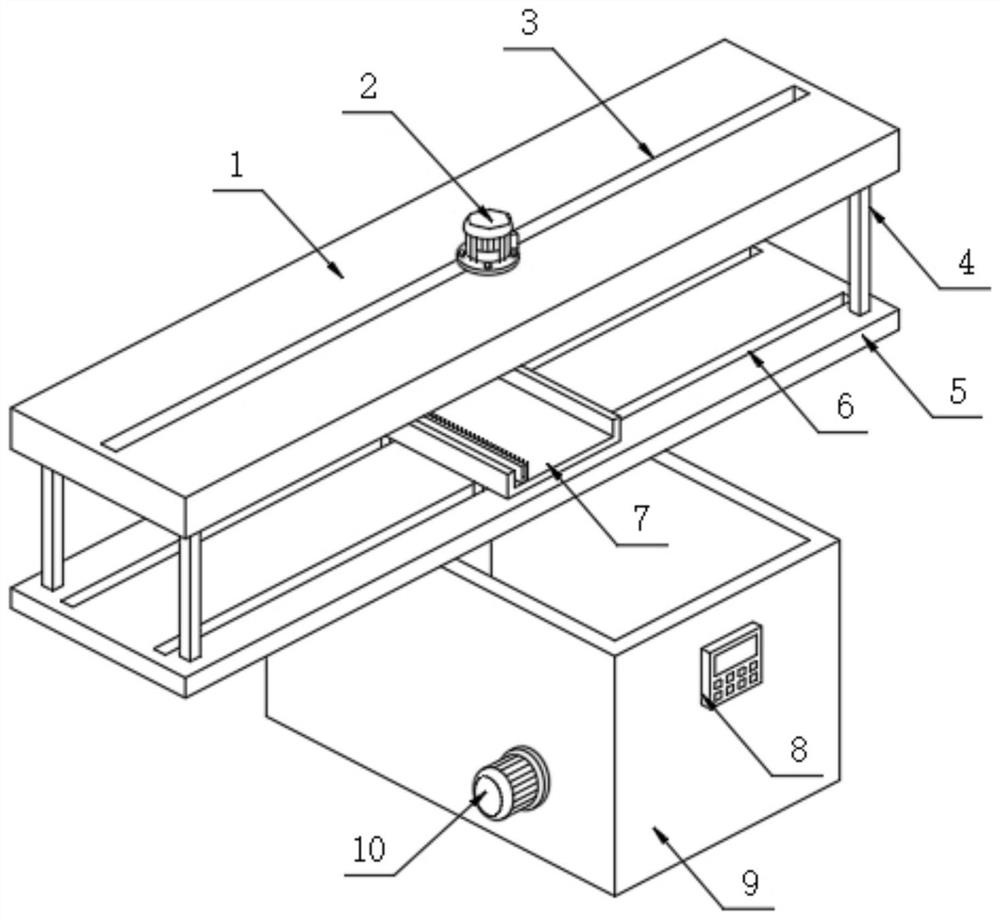

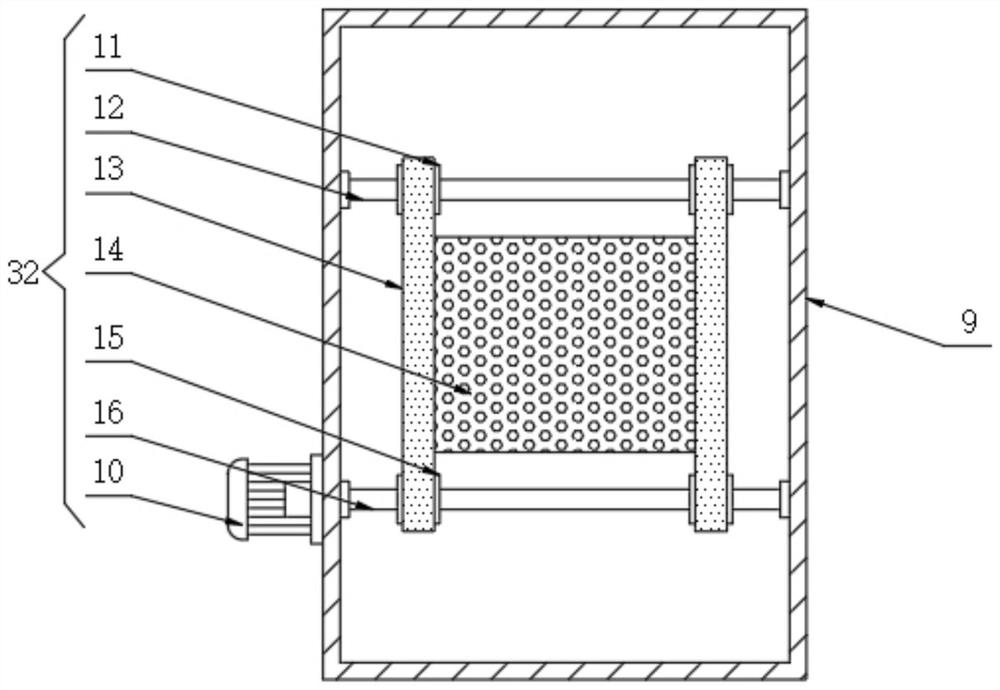

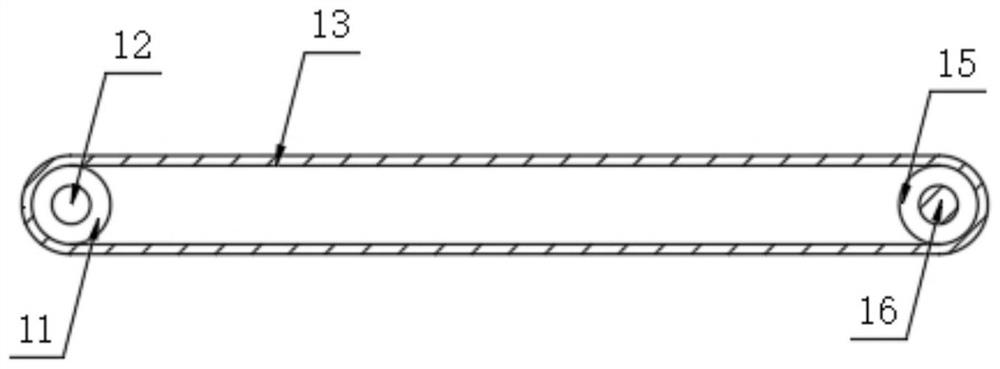

[0027] see Figure 1~5 , in an embodiment of the present invention, a square flat steel cold rolling, drawing integrated equipment, including a cold rolling pickling box 9, a controller 8 is fixed on the front surface of the cold rolling pickling box 9, and the cold rolling pickling box 9 The rear side of the upper surface of the box 9 is fixedly connected with a support plate 5, the model of the controller 8 is DKC-Y110, the drive box 1 is installed above the support plate 5, and four alloys are fixedly connected between the support plate 5 and the drive box 1. Steel bracket 4, the middle part of the upper surface of support plate 5 is provided with two limit grooves 6 horizontally, and a clamping seat 7 is installed above the two limit grooves 6, and a slider is fixedly connected to the lower surface of the clamping seat 7. The block is slidingly connected to the inside of the limit groove 6, and the inside of the clamping seat 7 is movably equipped with a clamping plate 30,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com