Corn bran bacterial protein fermented feed and preparation method thereof

A technology of bacterial protein and fermented feed, applied in animal feed, animal feed, food processing and other directions, can solve the problems of high cellulose and hemicellulose content, poor palatability and feeding effect, and increased cost of main products. , to achieve a balanced ratio of amino acids, improve feed utilization, and improve the effect of disease resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1, the preparation of corn hull thalline protein fermented feed

[0062] 1. Preparation of corn husk protein fermented feed

[0063] 1. Preparation of primary fermentation agent

[0064] Aspergillus niger (Aspergillus niger) CGMCC 3.17612 was cultured on a slant in a wort agar medium at a temperature of 25°C; after the slant culture was completed, the fungus was picked and inoculated into a wort liquid medium for shake flask culture at a temperature of 25°C , 3d; after the shaking flask culture, inoculate the obtained culture solution into the corn bran solid-state fermentation basal medium for koji culture, the culture conditions are 25°C, 2-7d, and the Aspergillus niger inoculant is obtained after the culture is completed. The live bacteria content in the medium is 6.52×10 9 cfu / kg.

[0065] Bacillus subtilis (Bacillus subtilis) CGMCC 1.15792 was cultured on a slant in LB agar medium at a temperature of 37°C; 1d; After the shake flask culture is complet...

Embodiment 2

[0133] Embodiment 2, the detection of corn hull thalline protein fermented feed

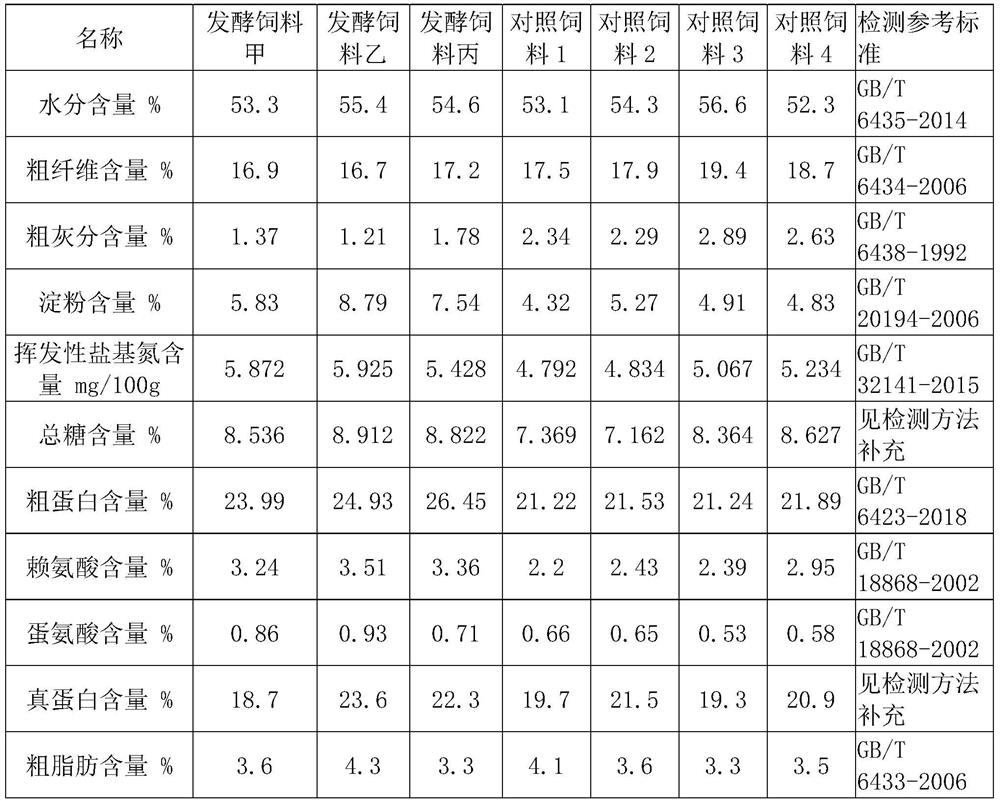

[0134] 1, the physicochemical index and the hygienic index of corn hull thalline protein fermented feed A-C that embodiment 1 obtains and contrast feed 1-4 are shown in Table 1 and 2.

[0135] Table 1 Test results of physical and chemical indicators of corn husk bacterial protein fermented feed

[0136]

[0137] As seen from Table 1, fermented feed A-C crude fiber content of the present invention is lower than the 18% that protein feed stipulates, meets the protein feed requirement, and contrast feed 3-4 is higher than 18%, does not meet the protein feed requirement; Fermented feed A-C The crude protein content of C and control feeds were all greater than 20% of the protein feed requirement, meeting the requirements of protein feed, and the crude protein content of each fermented feed was significantly higher than that of the control feed.

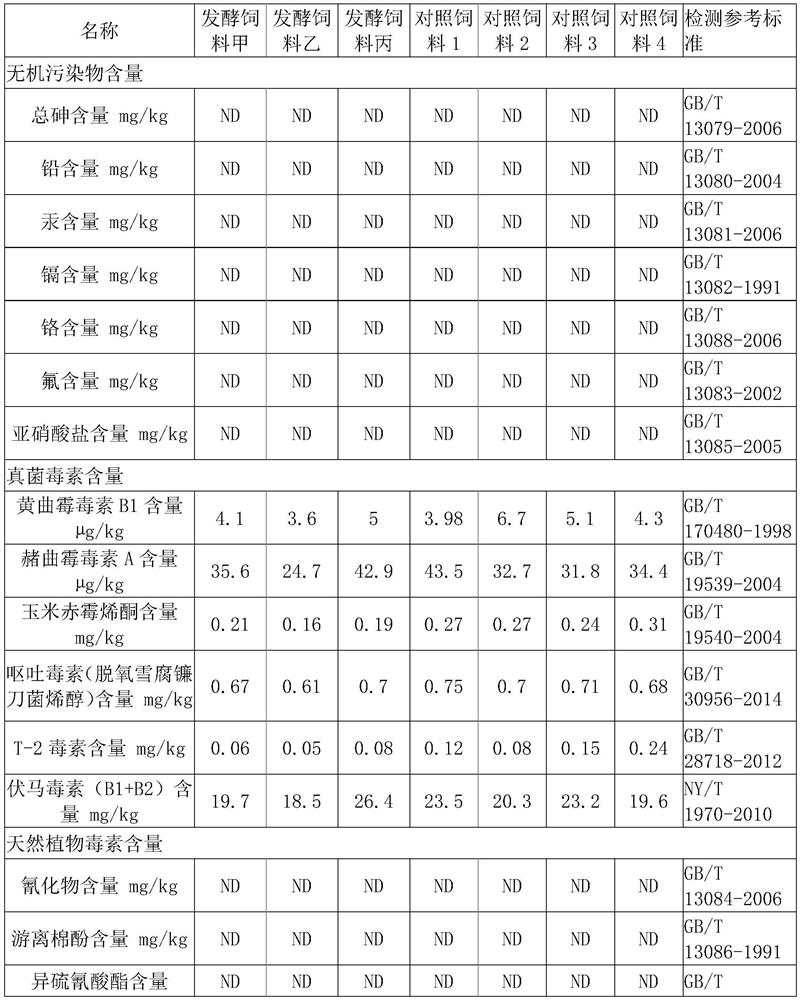

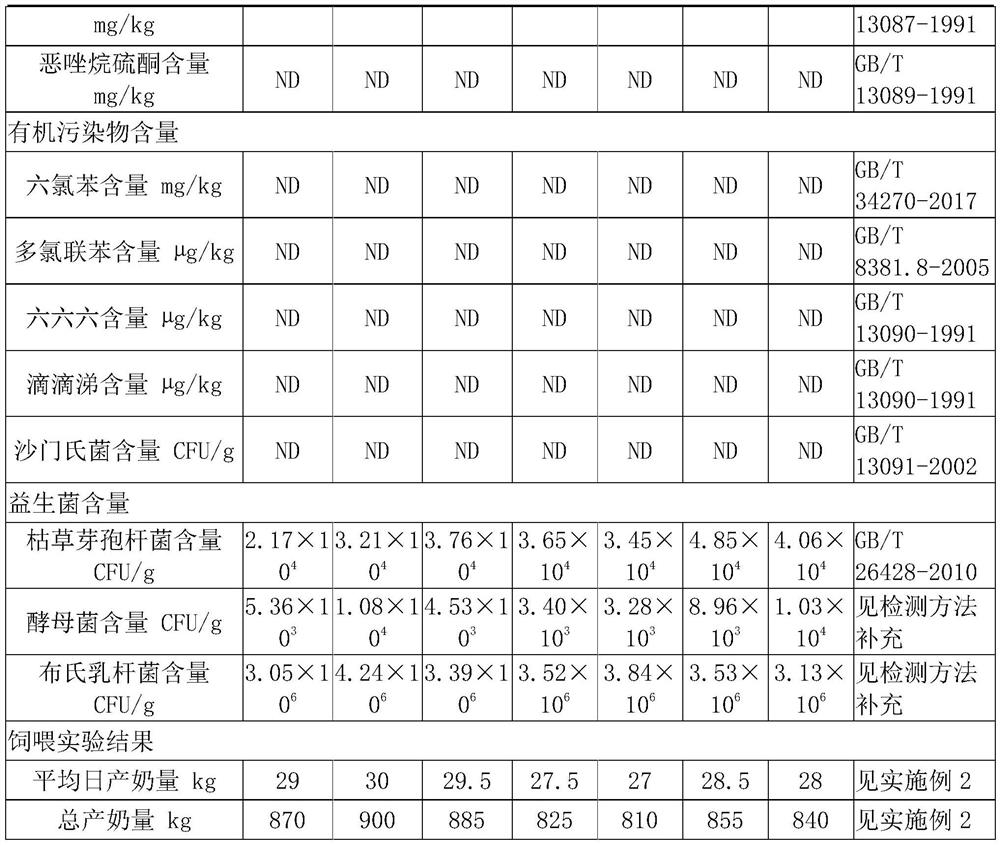

[0138] Table 2 The detection results of hygienic in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com