High-end equipment manufacturing process quality online monitoring method and system

A technology of manufacturing process and equipment, applied in the field of online monitoring of high-end equipment manufacturing process quality, can solve the problem of inability to accurately monitor the quality of high-end equipment manufacturing process online, and achieve the effect of accurate online monitoring results, improved processing capacity, and improved classification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

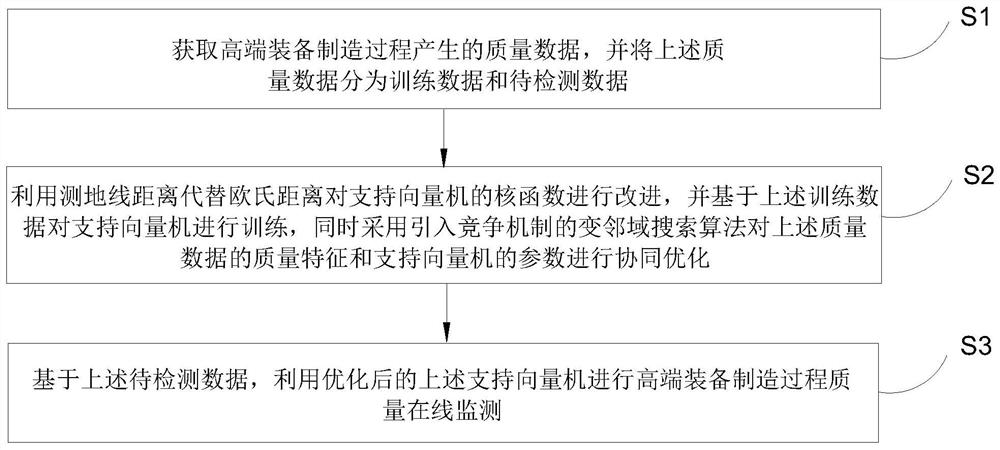

[0065] In the first aspect, the embodiment of the present invention first proposes an online monitoring method for the quality of high-end equipment manufacturing process, see figure 1 , the method includes:

[0066] S1. Obtain the quality data generated in the high-end equipment manufacturing process, and divide the above quality data into training data and data to be tested;

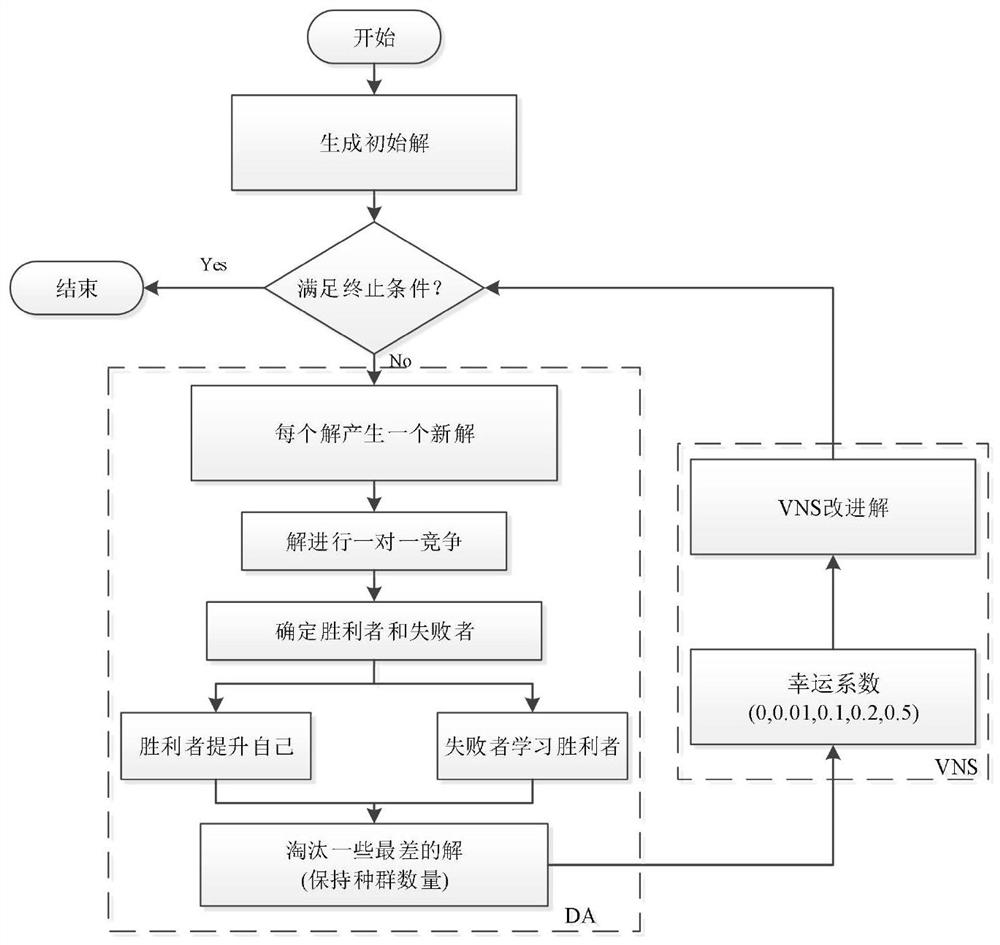

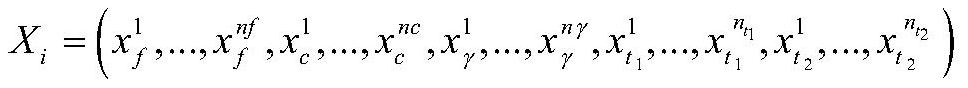

[0067] S2. Using the geodesic distance instead of the Euclidean distance to improve the kernel function of the support vector machine, and based on the above training data, the support vector machine is trained. Co-optimize the parameters of quality features and support vector machines;

[0068] S3. Based on the above-mentioned data to be detected, use the above-mentioned optimized support vector machine to perform online monitoring of the quality of the high-end equipment manufacturing process.

[0069] It can be seen that in the online monitoring method and system of high-end equipment manufacturin...

Embodiment 2

[0119] In the second aspect, the present invention also provides an online monitoring system for high-end equipment manufacturing process quality, the system includes:

[0120] A data acquisition module, configured to acquire quality data generated during the high-end equipment manufacturing process, and divide the quality data into training data and data to be tested;

[0121] The model training and optimization module is used to improve the kernel function of the support vector machine by using the geodesic distance instead of the Euclidean distance, and train the support vector machine based on the training data, and adopt the variable neighborhood search of introducing a competition mechanism at the same time The algorithm performs collaborative optimization on the quality features of the quality data and the parameters of the support vector machine;

[0122] The quality detection module is used to conduct online quality monitoring of the high-end equipment manufacturing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com