Side cloud collaborative digital twin intelligent production scheduling application operation position adaptation method

A kind of application operation and digital technology, applied in the field of edge computing, industrial intelligent production scheduling, and digital twin, can solve the problem that it is difficult to carry digital twin intelligent production scheduling application, so as to reduce performance loss, reduce production scheduling decision-making cycle, and improve performance effect on reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] like Figure 4 As shown, the deterministic adaptation method of the deployment location of the industrial digital twin intelligent production scheduling application based on edge-cloud collaboration of the present invention includes the following steps:

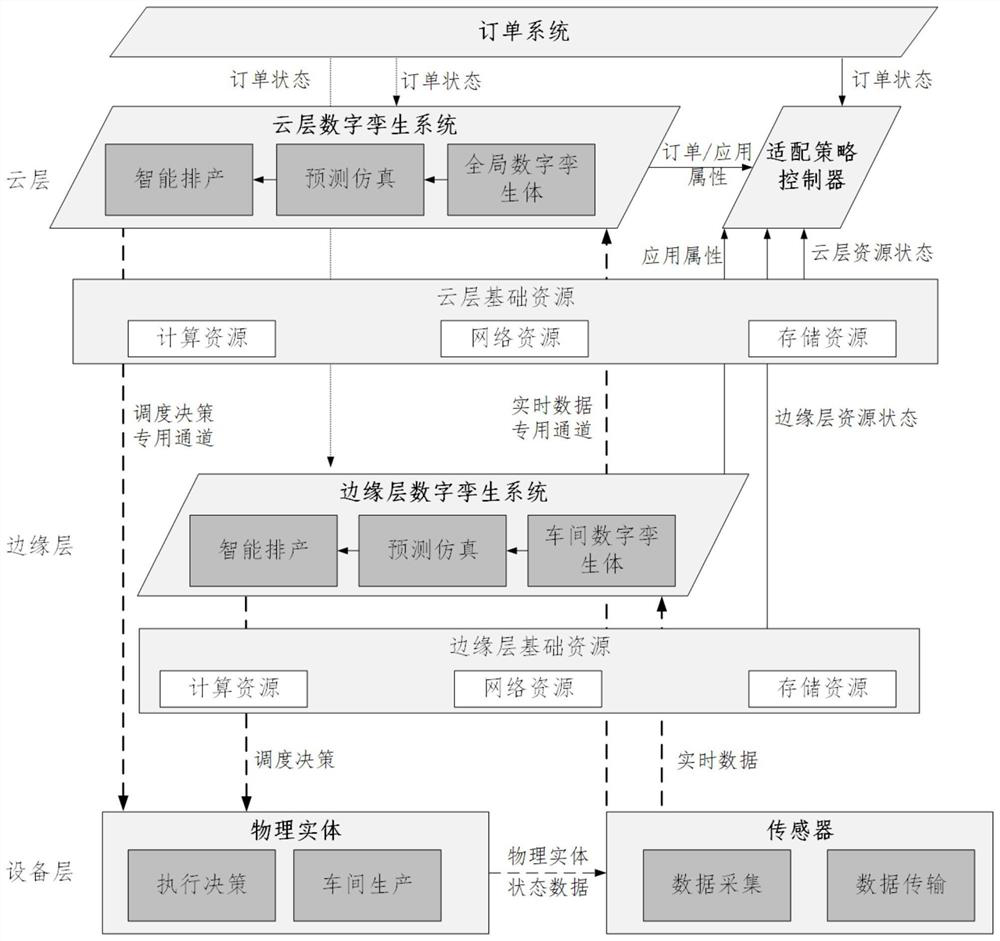

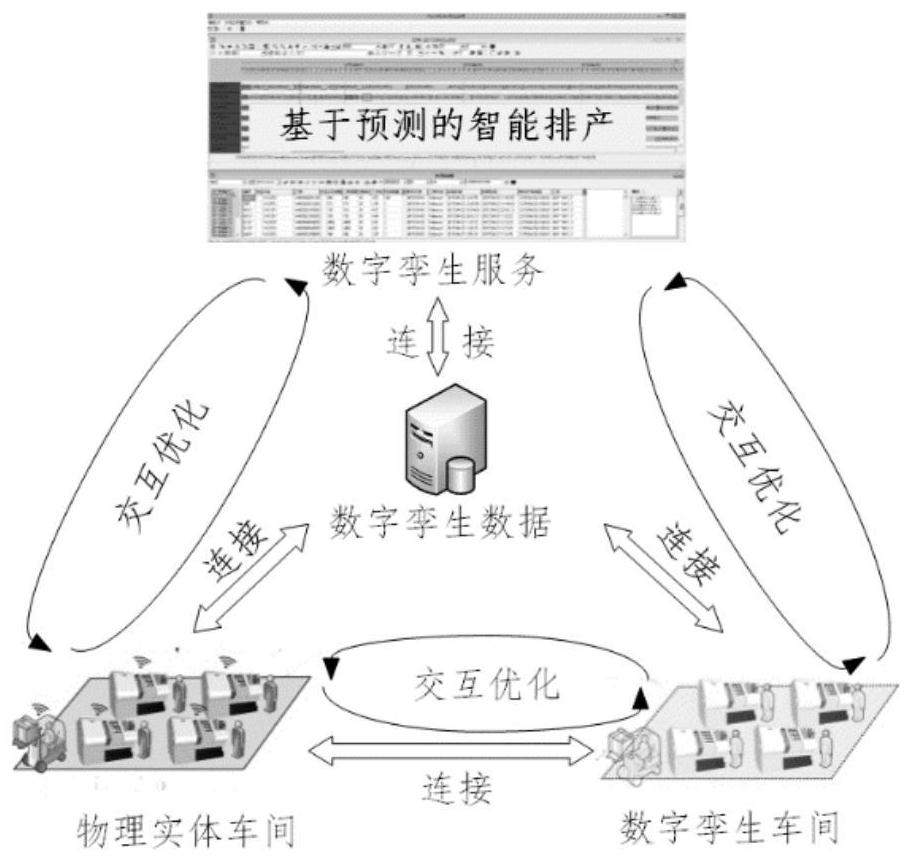

[0096]First, build a digital twin intelligent scheduling system architecture based on edge-cloud collaboration. This architecture has three layers, including the device layer, edge layer, and cloud layer.

[0097] In the embodiment of the present invention, in the constructed device layer, it is considered that there are 5 sensor devices in the workshop, and the generated data volumes are respectively [0.5, 0.9, 0.6, 0.8, 0.7] Mb.

[0098] In the embodiment of the present invention, considering the dynamic change of computing resources at the edge layer, a Markov process is used to establish a dynamic change process of computing resource capabilities at the edge layer. Among them, the possible values of computing po...

Embodiment 2

[0105] like Image 6 As shown, the flow of the non-deterministic adaptation method for the deployment location of the industrial digital twin intelligent production scheduling application based on edge-cloud collaboration in the present invention is as follows.

[0106] First, build a digital twin intelligent scheduling system architecture based on edge-cloud collaboration. This architecture has three layers, including the device layer, edge layer, and cloud layer.

[0107] In the embodiment of the present invention, at the device layer, it is considered that there are 5 sensor devices in the workshop, and the generated data volumes are respectively [0.5, 0.9, 0.6, 0.8, 0.7] Mb.

[0108] In the embodiment of the present invention, considering the dynamic change of computing resources at the edge layer, a Markov process is used to establish a dynamic change process of computing resource capabilities at the edge layer. Among them, the possible values of computing power are [2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com