Cutting assembly of cutting pump

A technology of components and cutting blades, which is applied to pump elements, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of small water inlet area, incomplete crushing of fibrous objects, and poor crushing effect of debris. , to achieve the effect of increasing the water inlet area, increasing the practical efficiency and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

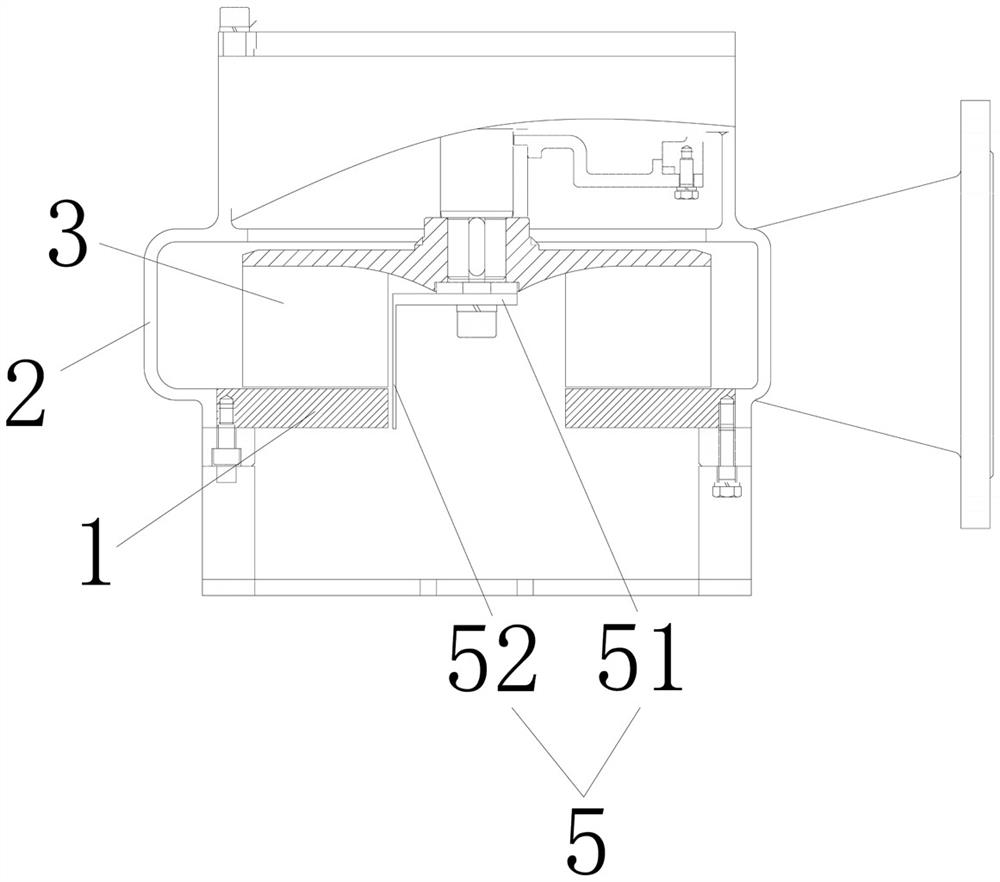

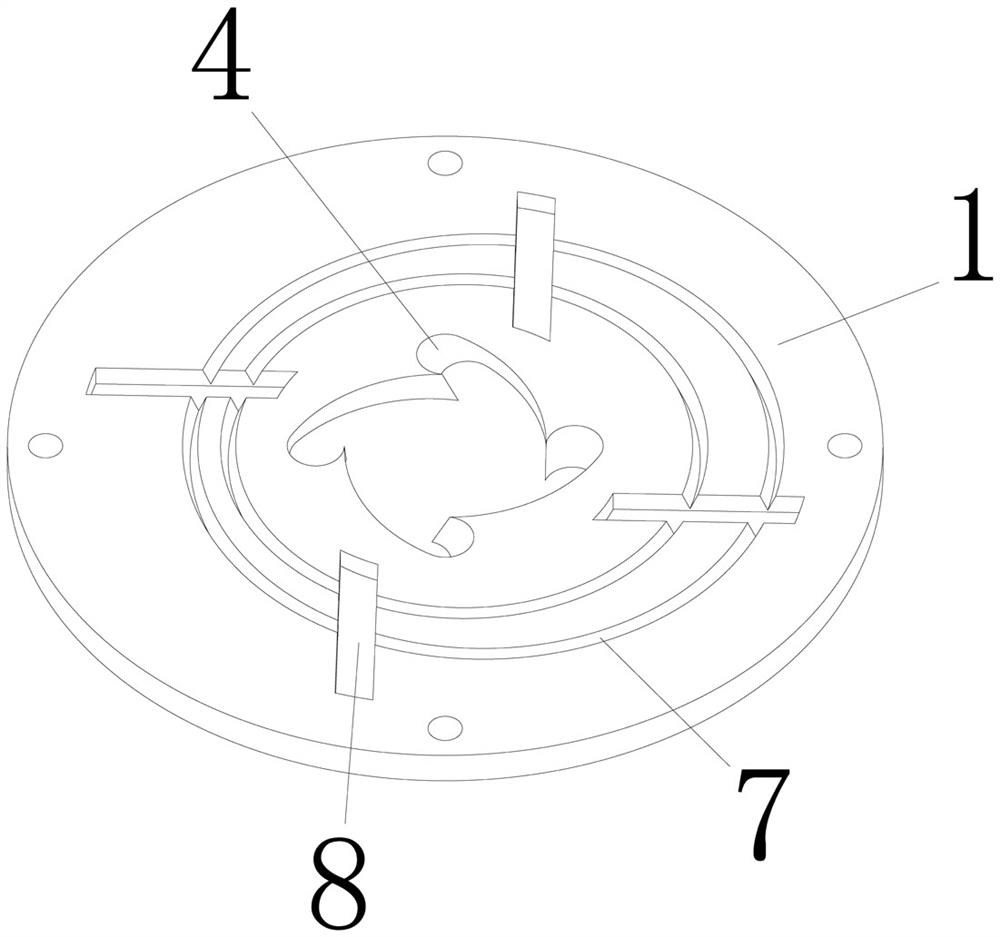

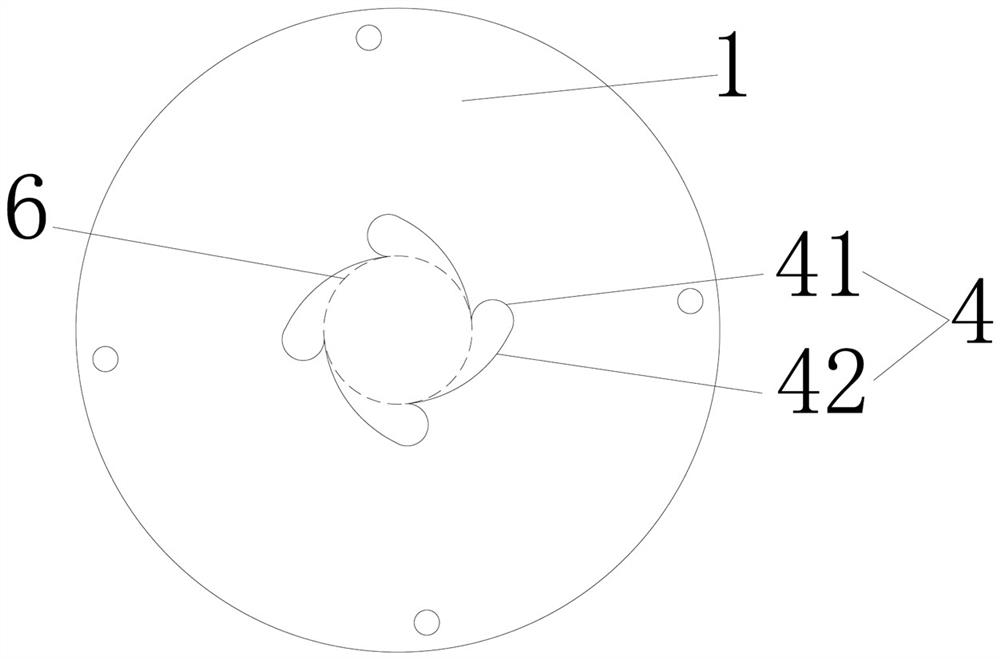

[0018] Embodiment 1: A cutting assembly of a cutting pump, including a pump cover 1, a volute 2 and a semi-open impeller 3, the pump cover 1 is arranged at the lower part of the volute 2, and the semi-open impeller 3 is arranged on the volute 2 in a rotational manner Inside, the semi-open impeller 3 has blades arranged along the circumference, and the pump cover 1 is provided with a water inlet channel, which is surrounded by a number of arc walls 4, compared with a simple round hole water inlet structure , increasing the water inlet area; the arc wall 4 is evenly arranged along the circumference 6 with the axis of the pump cover 1 as the center, and the cross section of the arc wall 4 includes a first arc segment 41 and a second arc segment 42, adjacent to the first The circular arc section 41 is connected end to end by the second circular arc section 42. This structure divides a single water inlet into a large water suction port and several vortex-shaped small water suction p...

Embodiment 2

[0023] Embodiment 2: On the basis of Embodiment 1, the water inlet channel is arranged as a spiral structure along its axial direction, and the spiral rotation direction is the same as that of the semi-open impeller 3. The first circular arc segment 41 and the second circular arc segment The arc section 42 deflects along the axis of the pump cover 1 and the deflection angle is γ, the range of γ is 0°<γ≤90°, the water flow through the water inlet channel is smoother, and it rotates like a vortex in each small water suction port; in this embodiment γ is set to 20°, and in other embodiments, γ can also be set to 5°, 30°, 40°, 50°, 60°, 70°, 80°, 90° or other angles; the first arc segment One end of 41 is circumscribed to the circumference 6, and the other end of the first arc segment 41 is inscribed to one end of the second arc segment 42. The tangent structure makes the water flow smoother and easier to form a vortex. The other end of the second arc segment 42 is in contact with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com