SCR urea mixer

A mixer and urea technology, which is applied in the field of hot tail gas post-treatment and SCR urea mixer, can solve the problems of low ammonia conversion rate and insufficient atomization, and achieve the goal of solving urea crystallization, improving conversion rate, and uniform and full mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

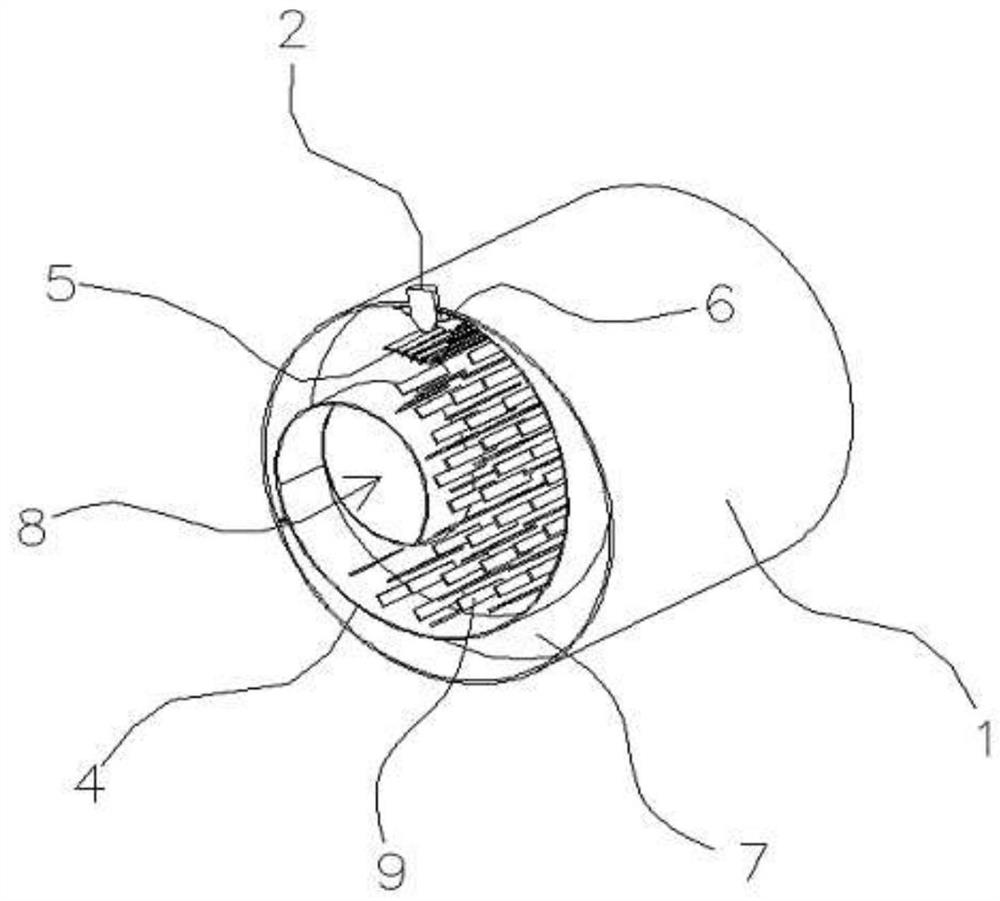

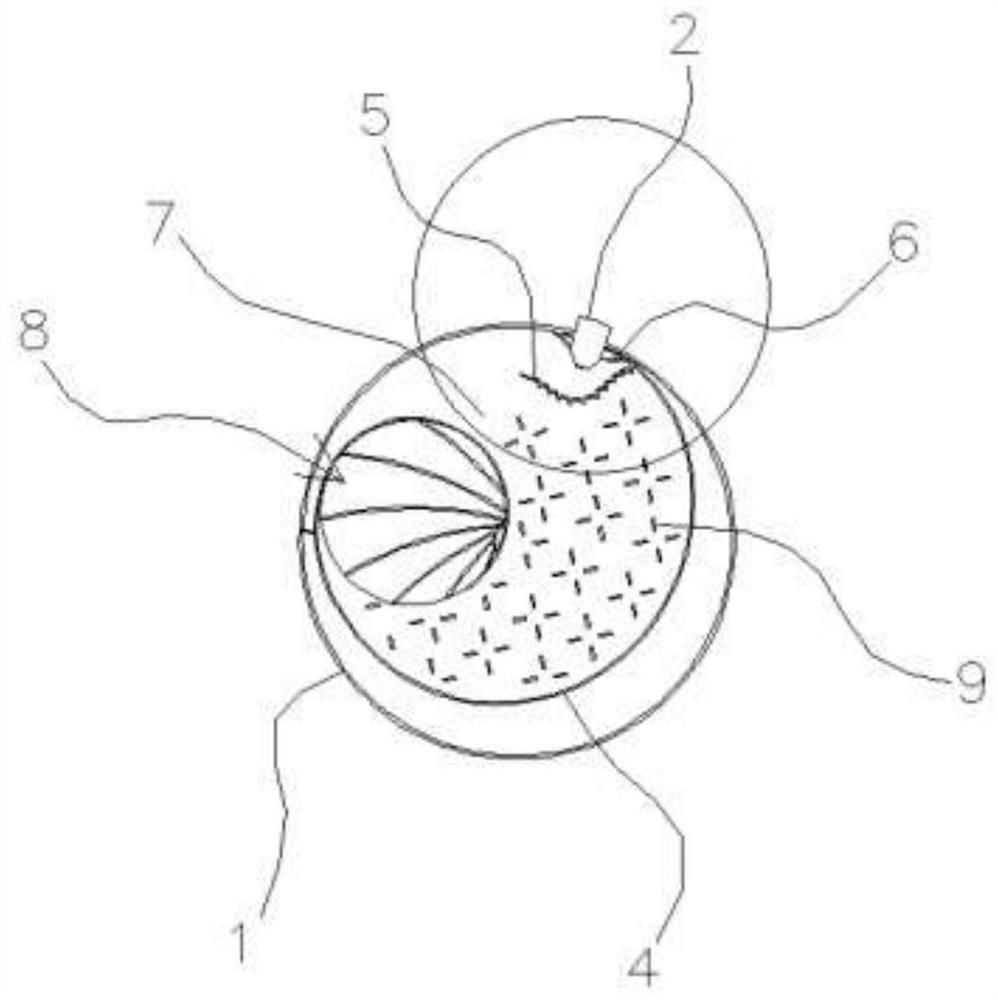

[0032] Attached below Figure 1-Figure 7 The specific structure of the SCR urea mixer given in this embodiment is described and explained.

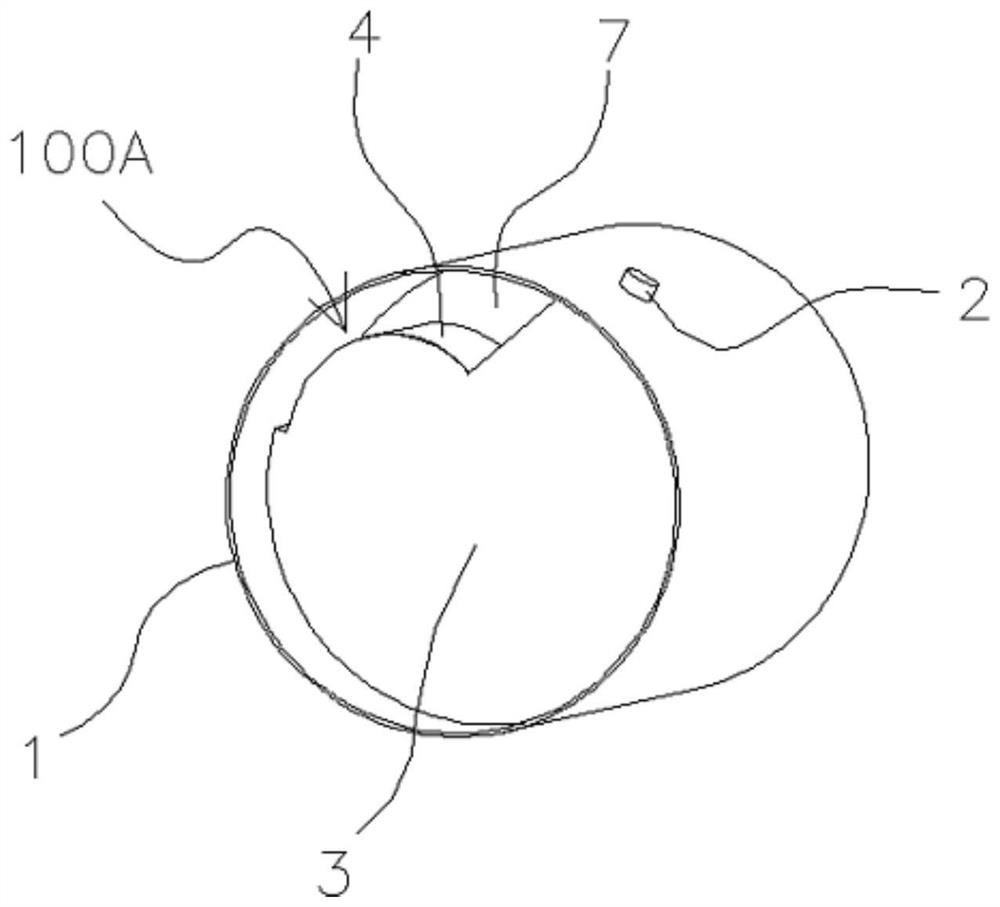

[0033] figure 1 It is the front view of the structure of the SCR urea mixer given in this example. The SCR urea mixer includes a cylinder 1, a urea nozzle mount 2 installed on the outer wall of the cylinder 1, an air inlet panel 3 arranged at the front end of the SCR urea mixer and an air outlet panel 7 at the rear end.

[0034] The axial air inlet 100A of the SCR urea mixer is formed by the cylinder body 1 , the air inlet end panel 3 and the spiral swirl deflector 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com