Dynamic mixer for urea-SCR (Selective Catalytic Reduction) system of diesel engine

A dynamic mixer, diesel engine technology, applied in machine/engine, mechanical equipment, engine components, etc., can solve problems such as increased engine exhaust back pressure and reduced fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The object of the present invention is to reduce the generation of deposits in the urea-SCR system by providing a dynamic mixer for the diesel engine urea-SCR system, improve the catalyst inlet velocity and NH 3 Concentration uniformity, while ensuring that its impact on engine exhaust back pressure is small.

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

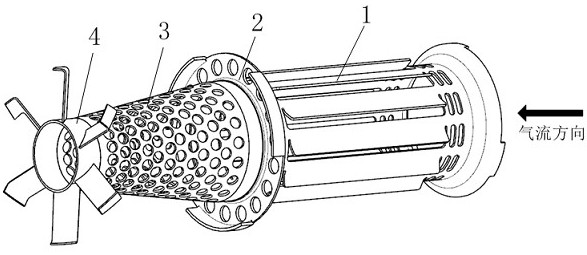

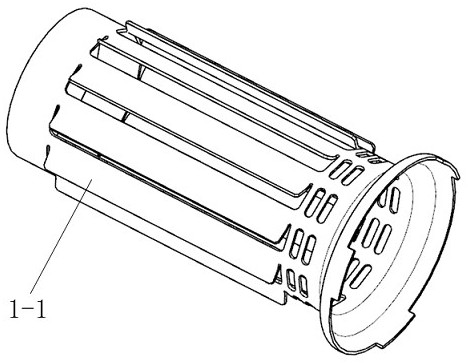

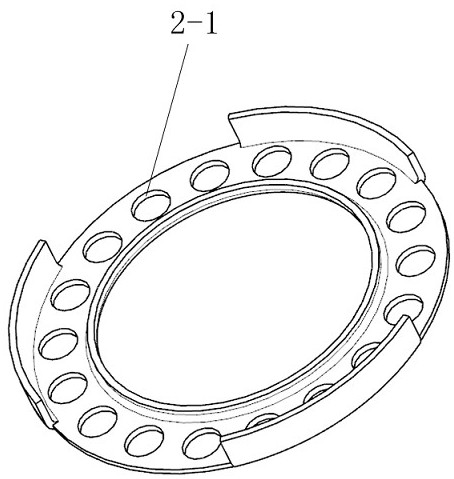

[0021] figure 1 As shown, the dynamic mixer used in the diesel engine urea-SCR system provided by this embodiment includes a swirl tube 1 , an annular baffle 2 , a porous conical tube 3 , and an impeller 4 . Connect according to the sequence of swirl tube 1, annular baffle plate 2, porous cone tube 3, and impeller 4. The side wall of the swirl tube 1 is evenly arranged with the swirl sheets 1-1 along the axial direction, such as figure 2 shown. Evenly arrange baffle plate through holes 2-1 on the annular baf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com