Preparation method, product and application of nickel-based metal organic framework compound

An organic framework and metal-based technology, applied in the field of electrocatalysis, can solve the problems of single structural components, complex operation process, unfavorable large-scale preparation and research of catalytic active sites, etc., to achieve excellent catalytic activity, good conductivity, and cycle The effect of excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Get 0.2934g of nickel nitrate hexahydrate, 0.1722g of 2,5-thiophenedicarboxylic acid, 0.1570g of 4,4'-bipyridine, and then measure H 2 O 10ml, N,N-dimethylformamide 10ml, and pour it into a beaker, stir it with a glass rod, put it into an ultrasonic wave, and ultrasonically disperse it for 30 minutes; Hours, down to room temperature, suction filtration to obtain 0.2931g emerald green powder, which is a nickel-based metal organic framework compound.

[0042] Using the emerald green powder as a precursor, take 600mg and put it into a magnetic boat, under the protection of nitrogen, pyrolyze it at 700°C for three hours, and the heating rate is 5°C·min -1 , to obtain 280mg of black powder, which is the catalyst.

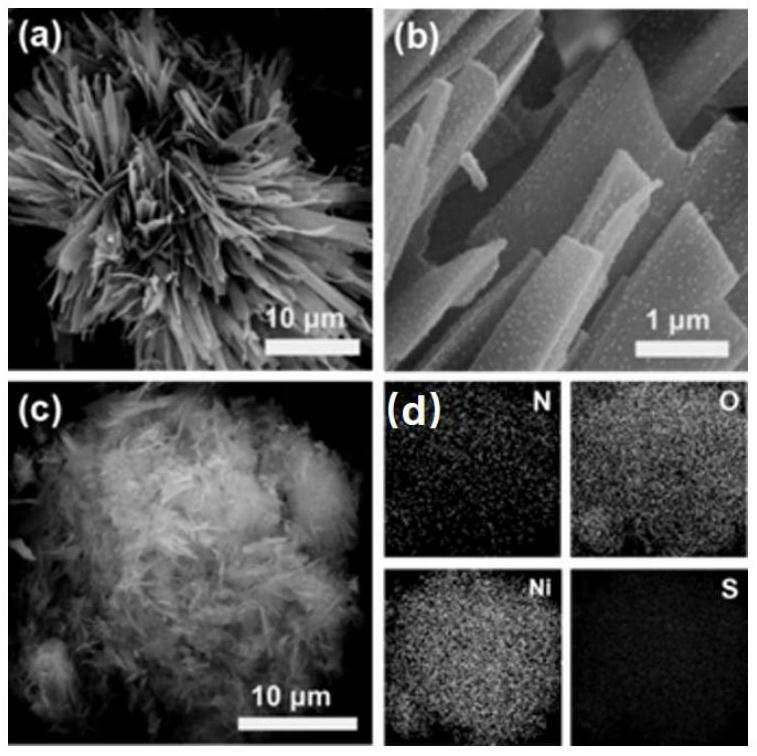

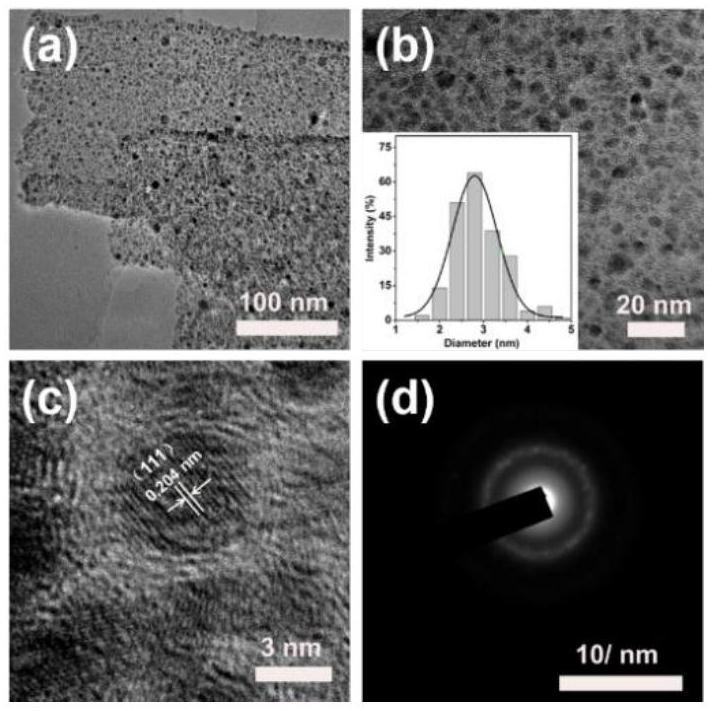

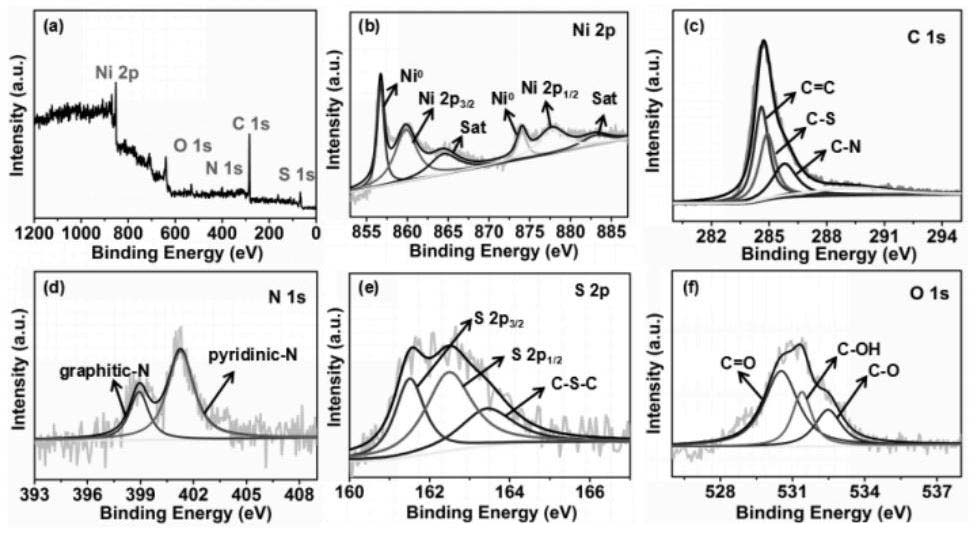

[0043] The FESEM figure of the catalyst prepared in this embodiment is shown in figure 1 ,Such as figure 1 As shown in a, the catalyst is flower-shaped composed of many long flakes with a length of 20 μm and a width of 1 μm. Depend on figure 1 b It can be see...

Embodiment 2

[0060] Same as Example 1, the only difference is that the process of preparing the black powder is pyrolysis at 600° C. for three hours. The performance of the catalyst prepared in this embodiment is shown in Image 6 ,from Image 6 It can be seen that the initial potential of the catalyst is 1.37V vs. RHE, and the maximum current density is 32.20mA cm -2 , outperforming commercial iridium carbon.

Embodiment 3

[0062] Same as Example 1, the only difference is that the process of preparing the black powder is pyrolysis at 800° C. for three hours. The performance of the catalyst prepared in this embodiment is shown in Figure 7 ,from Figure 7 It can be seen that the initial potential of the catalyst is 1.37V vs. RHE, and the maximum current density is 30.90mA cm -2 , outperforming commercial iridium carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com