Braille printing equipment and braille printed matter preparation method

A technology for printing equipment and printed matter, which is applied in the direction of printing, printing and printing devices for producing special varieties of printed matter, etc., can solve the problems of reduced printing efficiency, high requirements on substrates, rising costs, etc., and achieves saving of paper and ink, good touch, The effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

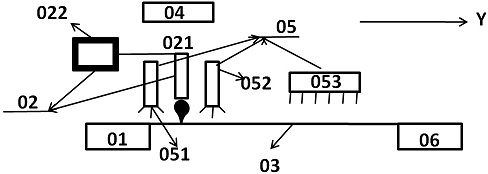

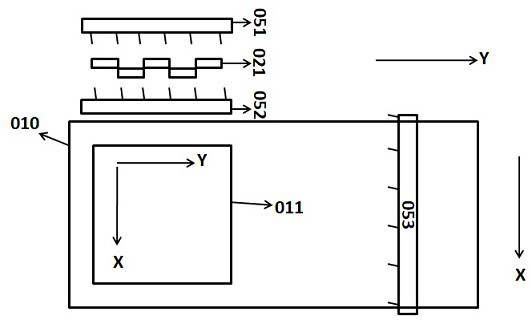

[0037] Braille printing devices such as Figure 1~2 , including a paper loading unit 01, a printing device 02, a conveying device 03, a visual positioning system 04, a curing device 05 and a delivery unit 06. The conveying device 03 conveys the substrate 011 along the Y direction of the Braille printing device 010 to the delivery unit 06 through the printing device 02 and the curing device 05; the printing device 02 can limit the printing area of the Braille printing device 010, and at least one printing nozzle 021 and print nozzle control system 022; the print nozzle 021 moves back and forth in a straight line along the Braille printing device 010X direction; the print nozzle control system 022 can control the number of ink jet holes and ink output of all print nozzles 021; The print nozzle 021 is installed by splicing, and the length of the print n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com