Negative plate, battery and preparation method of negative plate

A negative electrode sheet and negative electrode technology, applied to battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problem of insufficient negative electrode margin at the head of the battery cell, reduce the risk of lithium analysis, improve energy density, Effect of good ion diffusion kinetics on performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] See Figure 6 , Figure 6 It is a flow chart of a method for preparing a negative electrode sheet provided by an embodiment of the present invention. Such as Figure 6 As shown, the preparation method of the negative electrode sheet comprises:

[0069] Step 601, forming a negative electrode current collector, the surface of the negative electrode current collector includes a coating area and an empty foil area, and the empty foil area is used to set the negative electrode tab;

[0070] Step 602, coating the first coating slurry on the coating area to form a first coating, the first coating slurry is formed by mixing the first conductive agent, the first binder and the first active material become;

[0071] Step 603, coating a second coating slurry on the first coating to form a second coating, the second coating slurry is composed of a second conductive agent, a second binder and a second active material mixed;

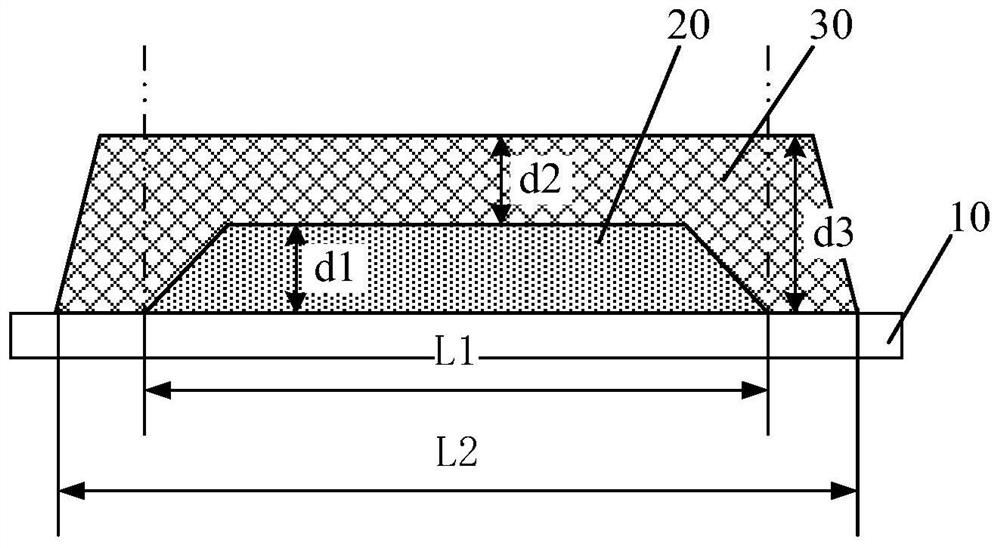

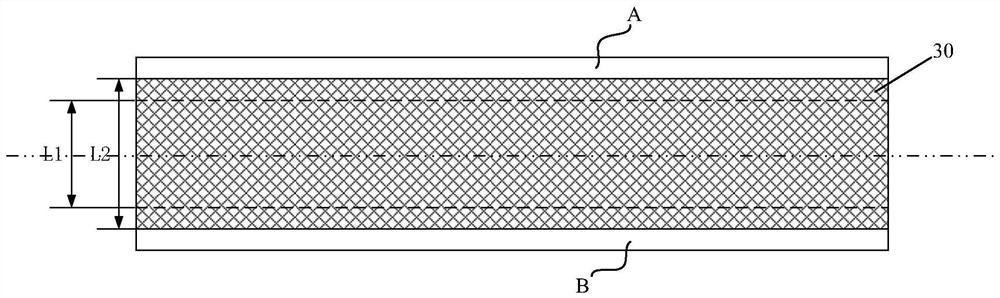

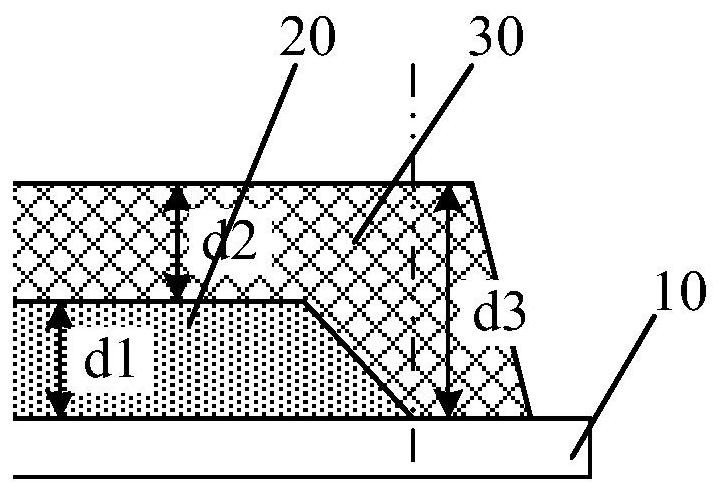

[0072] Wherein, the distance between the edge of th...

Embodiment and 3

[0079] Introduce below 3 kinds of specific embodiments and 3 kinds of comparative examples in 1 of the embodiment of the present invention:

Embodiment 1

[0081] Step 1. Prepare the first coating slurry with the first active material: according to the ratio of 96.8% of the first active material, 1.2% of the first conductive agent, and 2% of the first binder, it is prepared based on a certain batching process The first coating slurry has a viscosity of 2000-5000mPa.s and a solid content of 40%-50%.

[0082] Step 2. Prepare the second coating slurry with the second active material: according to the ratio of 96.8% of the second active material, 1.2% of the second conductive agent, and 2% of the second binder, it is prepared based on a certain batching process As for the second coating slurry, the viscosity of the second coating slurry is 2000-5000mPa.s, and the solid content is 40%-50%.

[0083] Step 3. After passing the first coating slurry prepared by step 1 above through a screen, coat the coating area with the negative electrode current collector to form a first coating, and then apply the slurry prepared by step 2 After the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com