Flexible silver selenide-based thermoelectric thin film and preparation method thereof

A technology of thermoelectric thin film and silver selenide, which is applied in the manufacture/processing of thermoelectric devices, and lead wire materials of thermoelectric device junctions, can solve the problems of high cost and poor thermoelectric performance of silver selenide thin film, and achieves low cost, Suitable for large-scale industrial production, high-purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Ag 2 Preparation of Se flexible thermoelectric thin film:

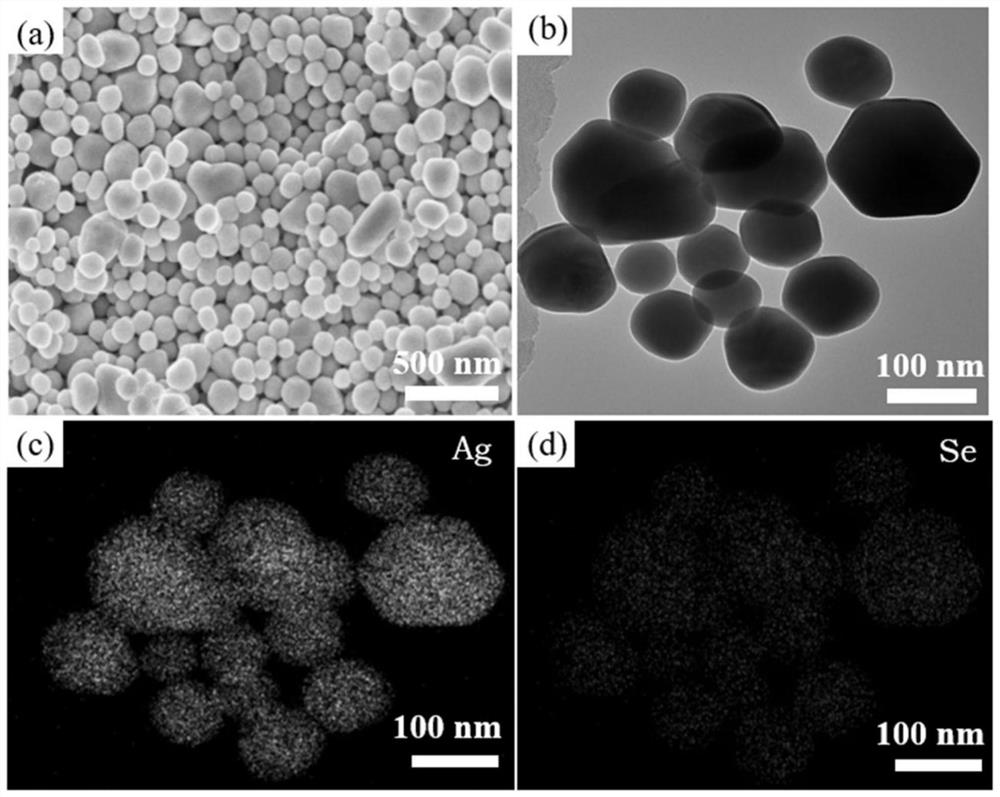

[0047] 1) Weigh 0.5g PVP and dissolve it in 20mL DMF, then add 26.3mg selenium dioxide and 82.9mg silver nitrate while stirring, then add 10mL OA, stir magnetically at room temperature for 8-10min, then pour the mixed solution into a 50mL reaction kettle and heated to 120°C for 12 hours. After the reaction is complete, wait for the reaction kettle to cool down to room temperature, centrifuge the reacted solution at a speed of 8000r / min for 10min, remove the upper layer solution, wash the obtained black powder by centrifugation, and then add absolute ethanol and Acetone was centrifuged at 8000r / min for 5min, washed three times respectively, and finally the centrifuged powder was dried under vacuum at 60°C for 6h to obtain Ag 2 Se nanopowder. figure 1 The field emission scanning electron micrograph and transmission electron micrograph of the silver selenide nanopowder synthesized in this example are given, an...

Embodiment 2

[0051] Ag 1.9 Preparation of Se flexible thermoelectric thin film:

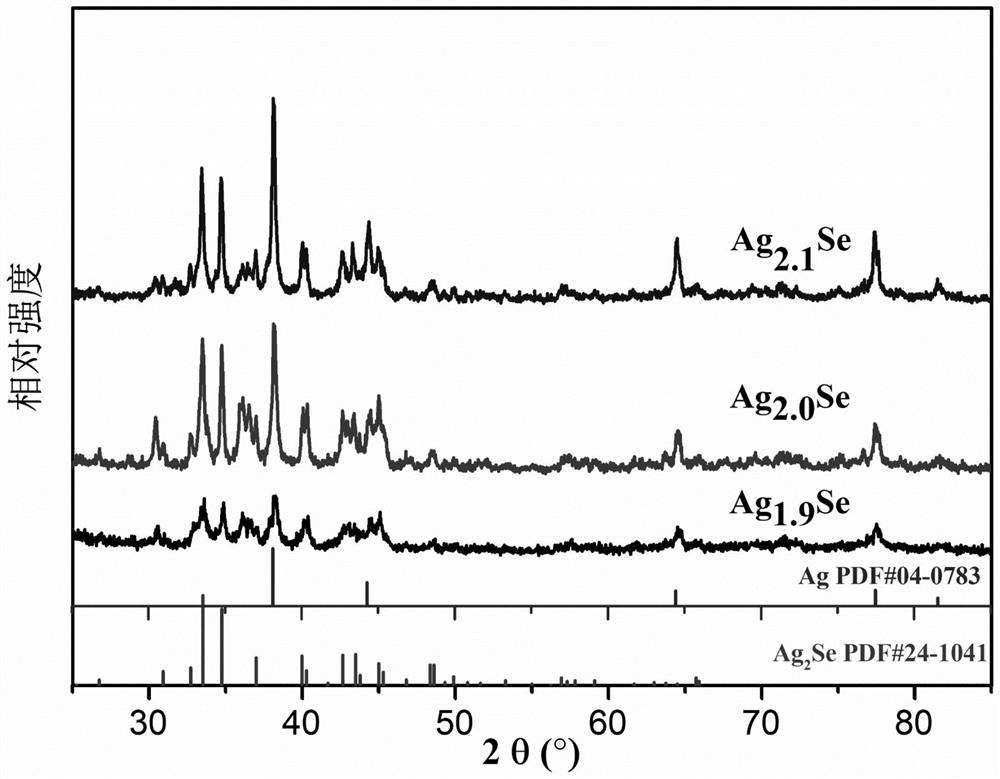

[0052] According to embodiment 1, change the silver nitrate consumption into 77.2mg in embodiment 1 step (1), all the other are identical with embodiment 1, obtain Ag 1.9 Se nanopowder, figure 2 The Ag synthesized in this example is given 1.9 Se nanopowder X-ray diffraction pattern, it can be seen from the figure: the synthesized Ag 1.9 The main phase of Se nanopowder is low-temperature silver selenide phase, which is consistent with its standard card (PDF#24-1041).

[0053] Ag 1.9 Preparation of Se nanopowder to obtain Ag 1.9 Se thermoelectric thin film, the specific process is the same as in Example 1.

[0054] The electrical conductivity of the film was measured by Loresta-GX high-precision four-probe instrument MCP-T700 to be 28.8 S / cm. The laboratory built a Seebeck coefficient test system based on the slope method, and recorded the potential difference ΔV generated by the film under different te...

Embodiment 3

[0056] Ag 2.1 Preparation of Se flexible thermoelectric thin film:

[0057] According to embodiment 1, change the silver nitrate consumption into 85.6mg in embodiment 1 step (1), all the other are identical with embodiment 1, obtain Ag 2.1 Se nanopowder. figure 2 The Ag synthesized in this example is given 2.1 Se nanopowder X-ray diffraction pattern, it can be seen from the figure: the synthesized Ag 2.1 The main phase of Se nanopowder is low-temperature silver selenide phase, which is consistent with its standard card (PDF#24-1041).

[0058] Ag 2.1 Preparation of Se nanopowder to obtain Ag 2.1 Se thermoelectric thin film, the specific process is the same as in Example 1.

[0059] The conductivity of the film was measured by Loresta-GX high-precision four-probe instrument MCP-T700 to be 48.3 S / cm. Using the self-built Seebeck coefficient test system based on the slope method in the laboratory, using Pall patch, infrared thermal imager (FOTRIC226) and nanovolt meter (Ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com