Amorphous silicon target material bearing device

A carrier device, amorphous silicon technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as increasing the cost of amorphous silicon targets, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The following examples are for more clearly explaining the technical solutions of the present invention without limiting the scope of the invention.

[0022] The technical solution of the specific implementation of the invention is:

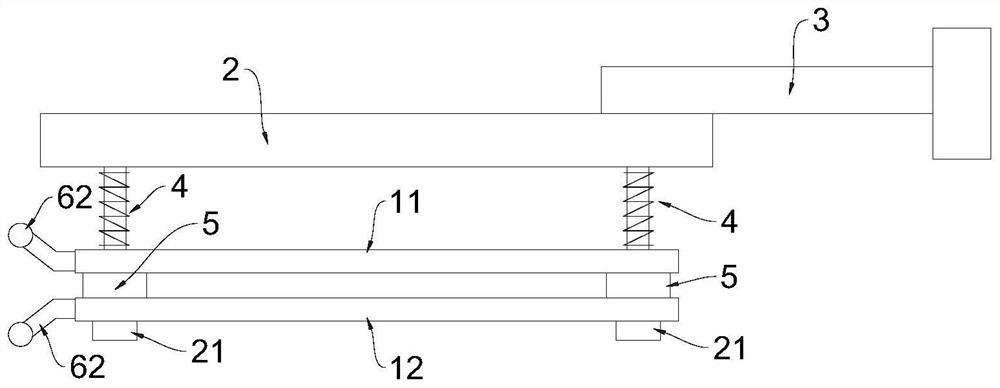

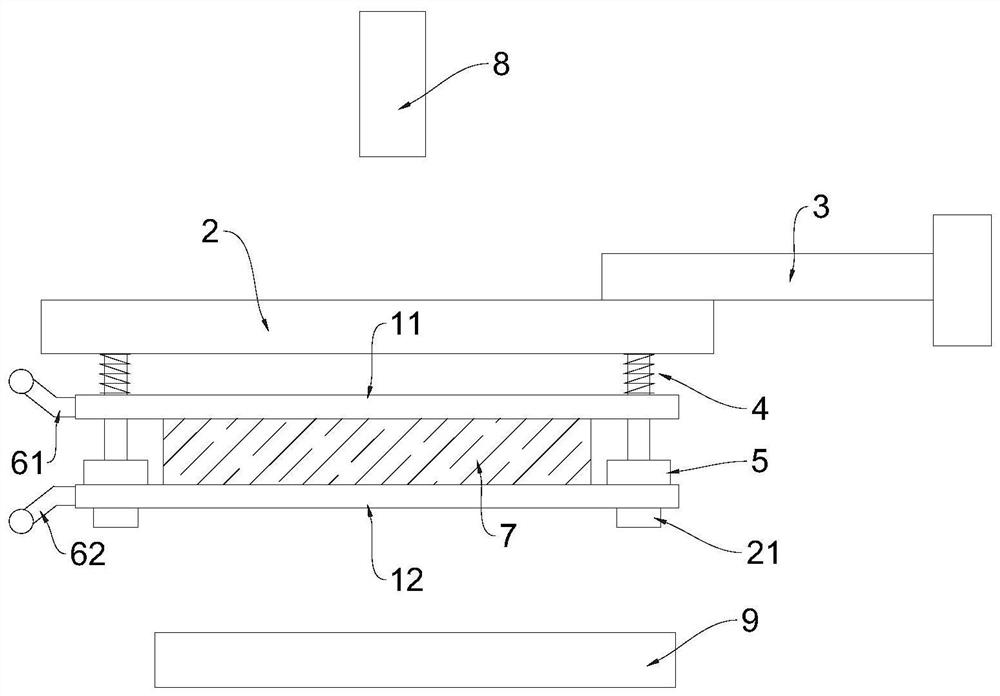

[0023] Such as figure 1 with figure 2 As shown, an amorphous silicon target carrier, including: a top panel 11 and a lower clamp 12 for clamping the plate-shaped amorphous silicon target 7 for supporting the top plate 2 of the upper splint 11 and the lower splint 12, And the top plate 2 is connected, and the moving device 3 for driving the top plate 2; the top plate 2, the upper splint 11 and the lower pinch 12 are rectangular; the upper splint 11 and the lower clamp 12 have a thickness of 0.05 to 2 mm;

[0024] The top plate 2 is disposed, and the top plate 2 is provided with a rectangular first hollow region, and the top plate 2 is also threaded to four vertical screws 21, which are located p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com