Device and method for testing performance of electromagnetic interference noise separator

A technology of noise separation and electromagnetic interference, which is used in measurement devices, environmental/reliability testing, measurement of interference from external sources, etc., to achieve the effect of effective targeted guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

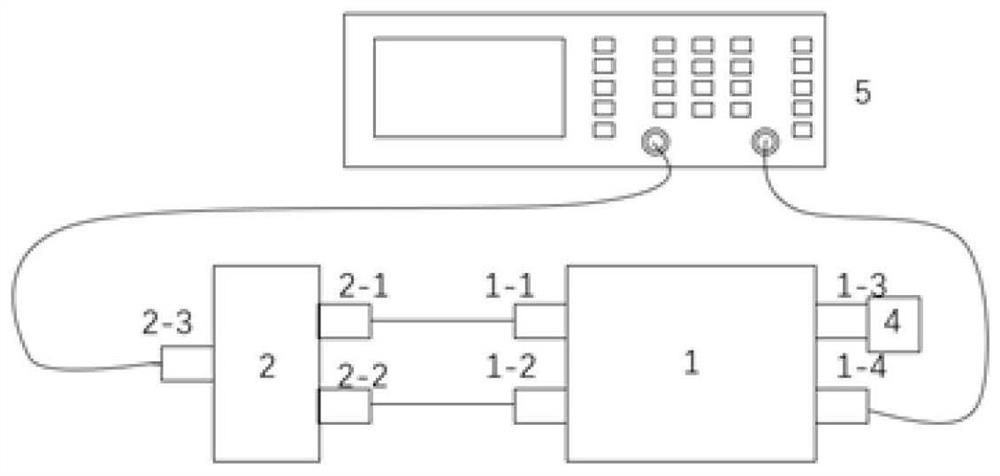

[0053] Common Mode Insertion Loss Test

[0054] The tested conducted noise separator 1 and the in-phase power divider 2 are respectively connected to the dual-port network analyzer 5 through a 50Ω coaxial cable, and the tested conducted noise separator 1 is connected to the in-phase power divider 2 through a 50Ω coaxial cable, The 50Ω matching load 4 is connected to the conducted noise separator 1 under test through a 50Ω coaxial cable.

[0055] The input port I11 is connected to the output port III21, the input port II12 is connected to the output port IV22, the output port I13 is connected to the 50Ω matching load 4, and the input port III23 and the output port II14 are respectively connected to the dual-port network analyzer 5.

Embodiment 2

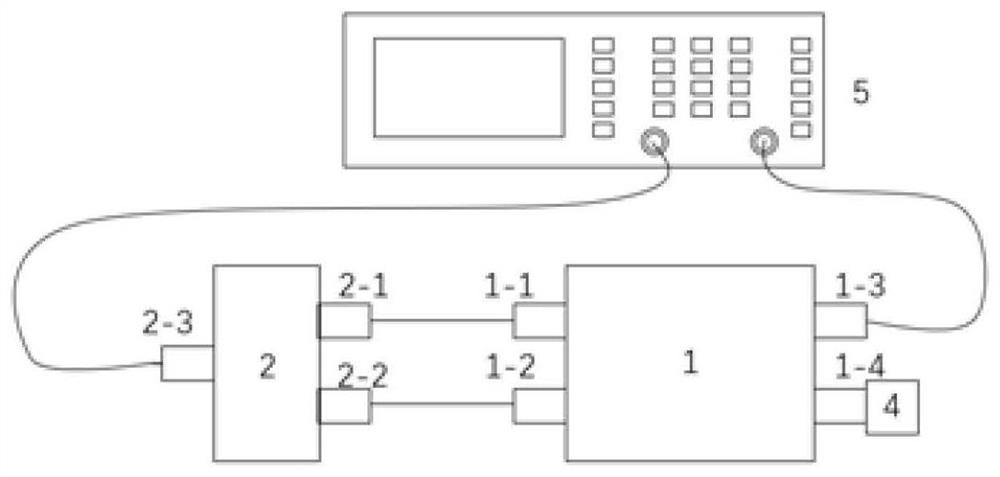

[0057] Common mode-differential mode isolation test

[0058] The tested conducted noise separator 1 and the in-phase power divider 2 are respectively connected to the dual-port network analyzer 5 through a 50Ω coaxial cable, and the tested conducted noise separator 1 is connected to the in-phase power divider 2 through a 50Ω coaxial cable, The 50Ω matching load 4 is connected to the conducted noise separator 1 under test through a 50Ω coaxial cable.

[0059] The input port I11 is connected to the output port III21, the input port II12 is connected to the output port IV22, the output port II14 is connected to the 50Ω matching load 4, and the input port III23 and the output port I13 are respectively connected to the dual-port network analyzer 5.

Embodiment 3

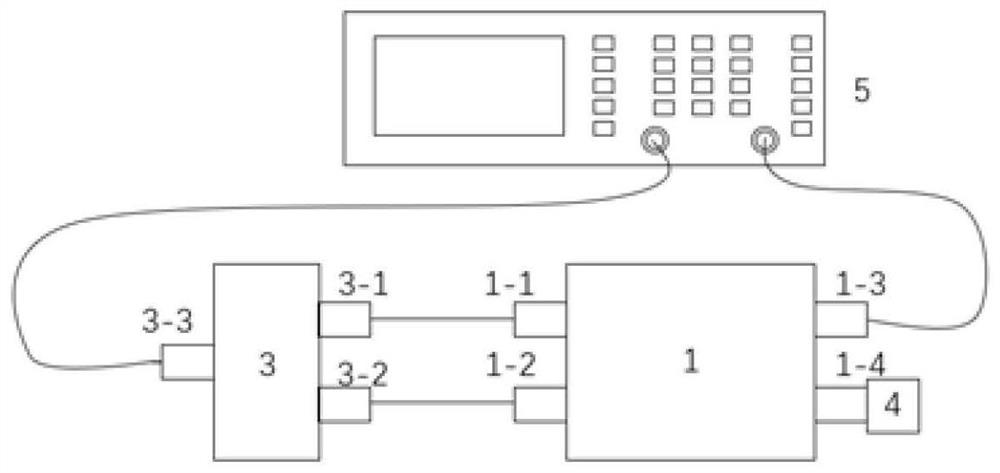

[0061] Differential Mode Insertion Loss Test

[0062] The tested conducted noise separator 1 and the inverting power divider 3 are respectively connected to the two-port network analyzer 5 through a 50Ω coaxial cable, and the tested conducted noise separator 1 is connected to the inverting power divider 3 through a 50Ω coaxial cable The 50Ω matching load 4 is connected to the tested conducted noise separator 1 through a 50Ω coaxial line.

[0063] The input port I11 is connected to the output port V31, the input port II12 is connected to the output port VI32, the output port II14 is connected to the 50Ω matching load 4, and the input port IV33 and the output port I13 are respectively connected to the dual-port network analyzer 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com