A route planning method and system for transport vehicles in a scrap steel base

A path planning and transport vehicle technology, which is applied in manufacturing computing systems, general control systems, control/regulation systems, etc., to achieve the effect of improving scrap steel recycling efficiency and saving queuing and waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

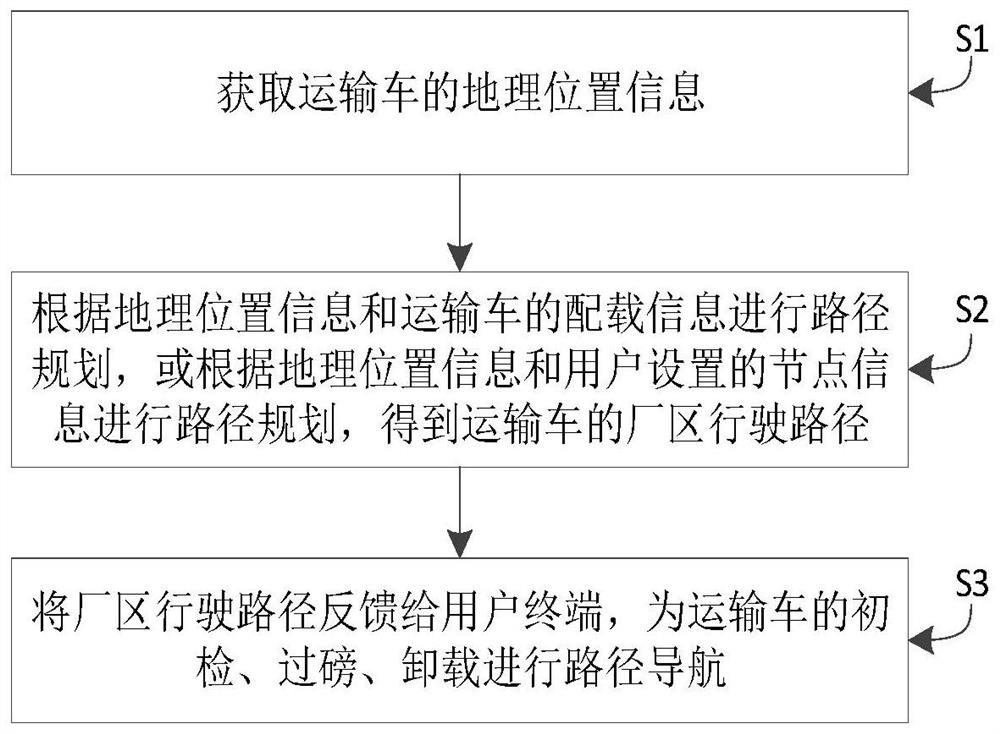

[0055] This embodiment provides a method for planning the route of a transport vehicle in a scrap steel base, such as figure 1 shown, including the following steps:

[0056] S1, obtaining the geographic location information of the transport vehicle;

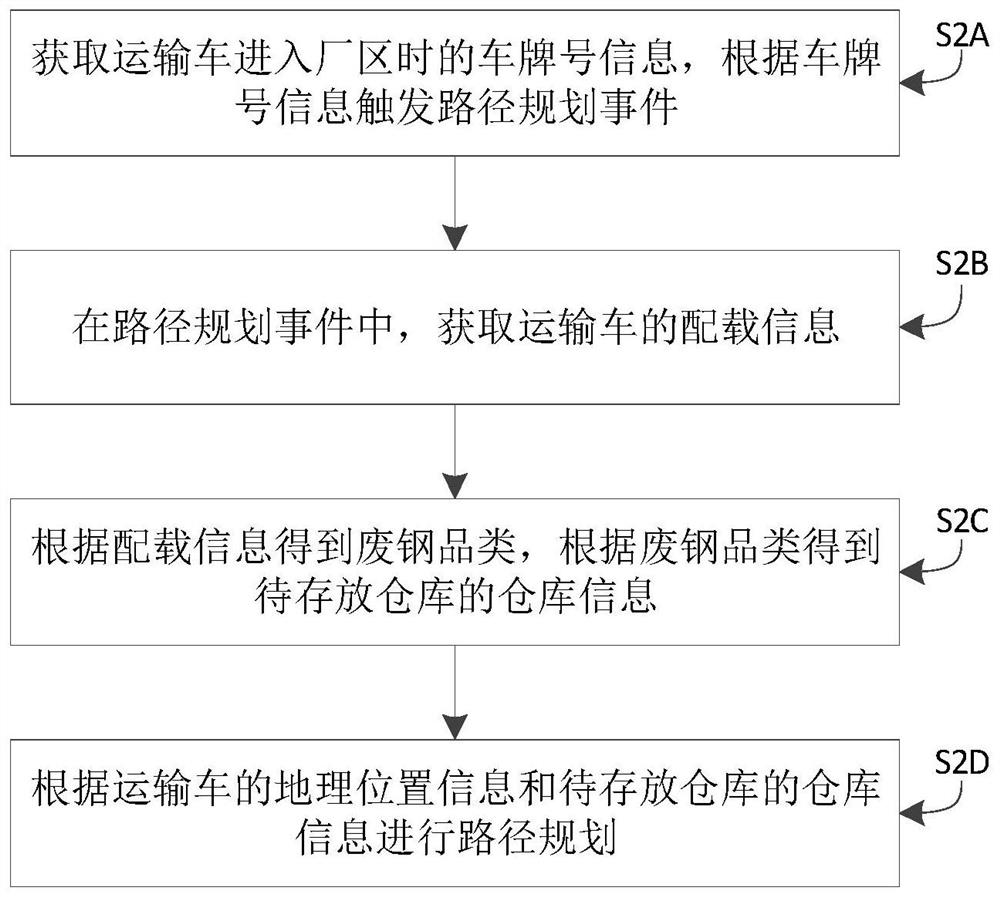

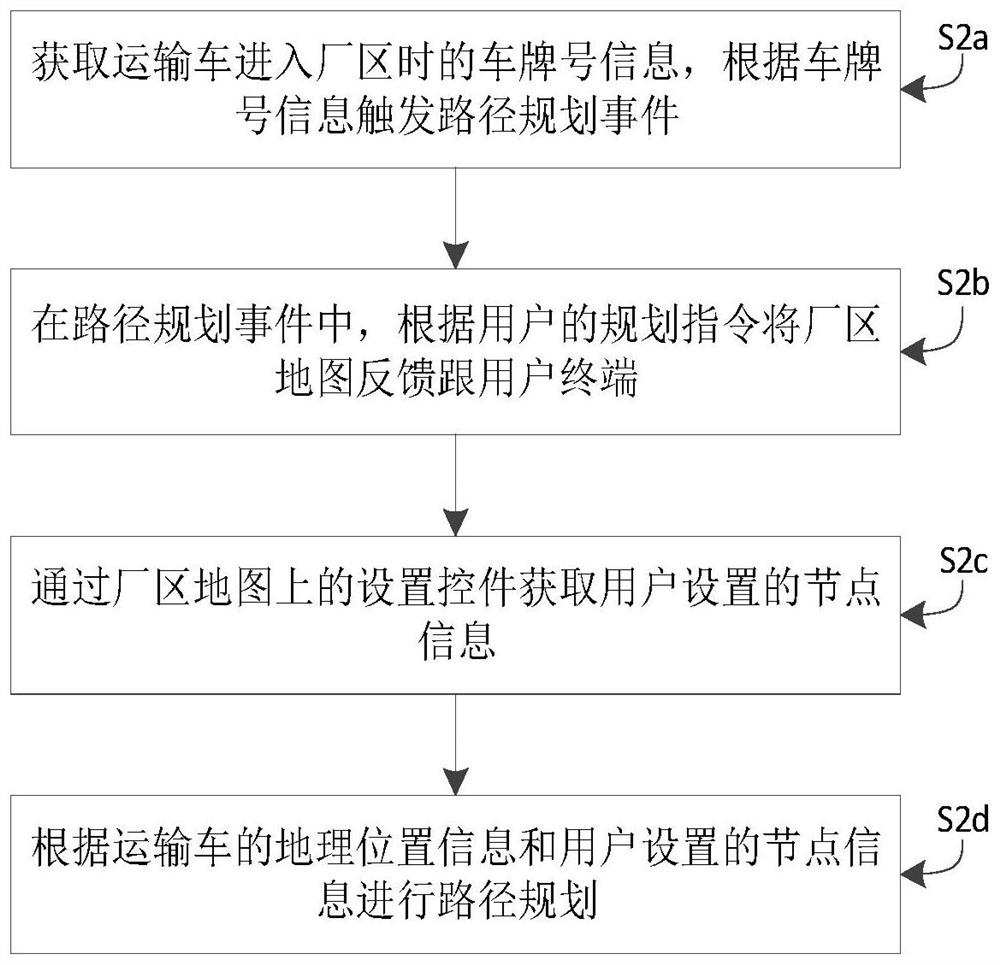

[0057] S2. Carry out path planning according to the geographical location information and the loading information of the transport vehicle, or perform path planning according to the geographical location information and the node information set by the user, and obtain the driving route of the transport vehicle in the plant area;

[0058] S3, feed back the driving path of the factory area to the user terminal, and perform path navigation for the initial inspection, weighing, and unloading of the transport vehicle.

[0059] In this embodiment, there are multiple initial inspection checkpoints and multiple warehouses in the factory area. The multiple warehouses store different types of scrap steel respectively. Each warehouse has mul...

Embodiment 2

[0103] This embodiment provides a route planning system for a scrap steel base transport vehicle, which is applicable to the route planning method for a scrap steel base transport vehicle described in Embodiment 1, such as Figure 4 As shown, the system includes a remote server and a user terminal communicating with each other, and the remote server includes:

[0104] a location acquisition unit, configured to acquire geographic location information of the transport vehicle;

[0105] The path planning unit is used to perform path planning according to the geographic location information and the loading information of the transport vehicle, or to perform path planning according to the geographic location information and the node information set by the user, to obtain the factory driving path of the transport vehicle;

[0106] The path navigation unit is used to feed back the driving path of the factory area to the user terminal, and perform path navigation for the initial inspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com