Elastic pile foundation resistant to frost heaving damage

An elastic pile and frost heave technology, applied in infrastructure engineering, sheet pile walls, protection devices, etc., can solve the problems of increasing labor consumption, increasing construction costs, and being unfriendly to the environment, reducing construction difficulty and labor intensity, reducing Maintenance cost and the effect of facilitating post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

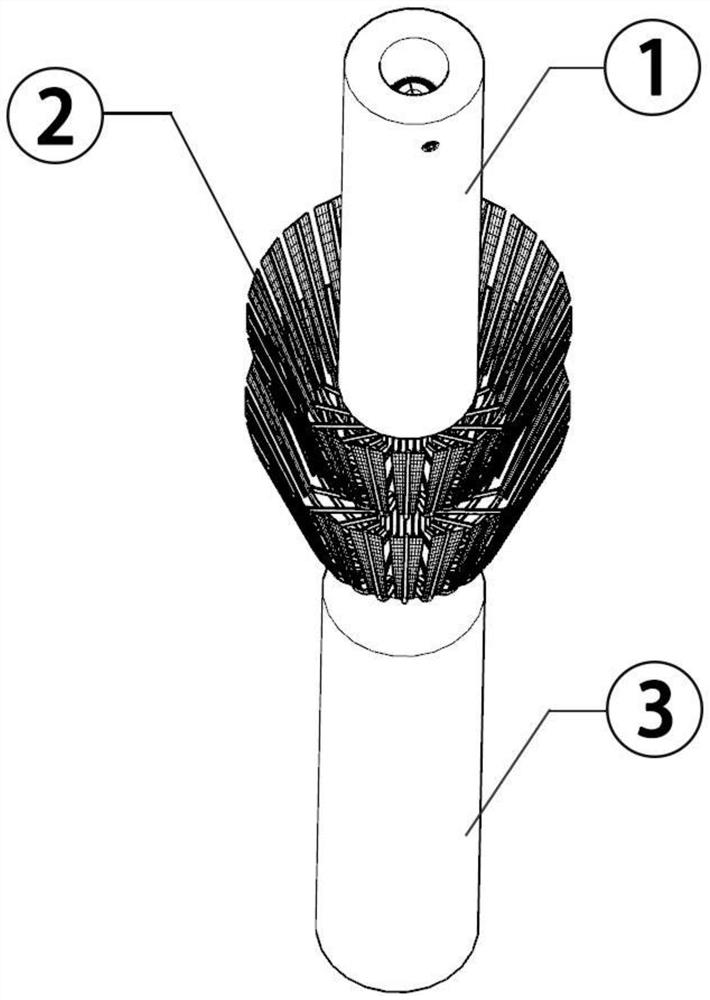

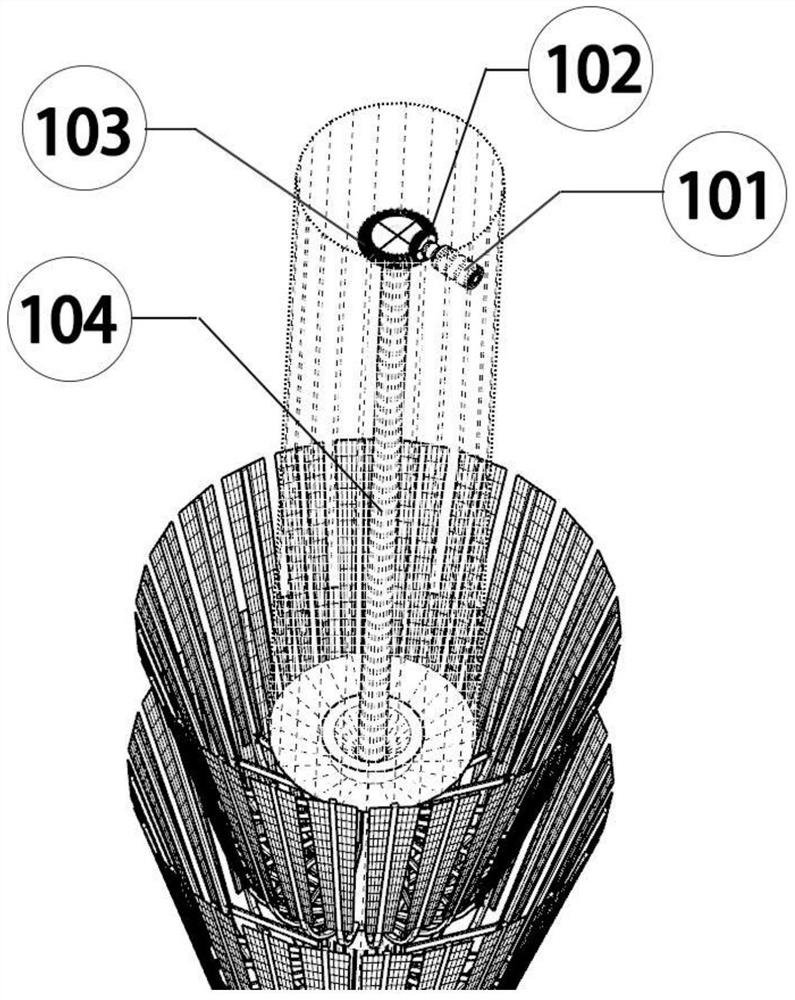

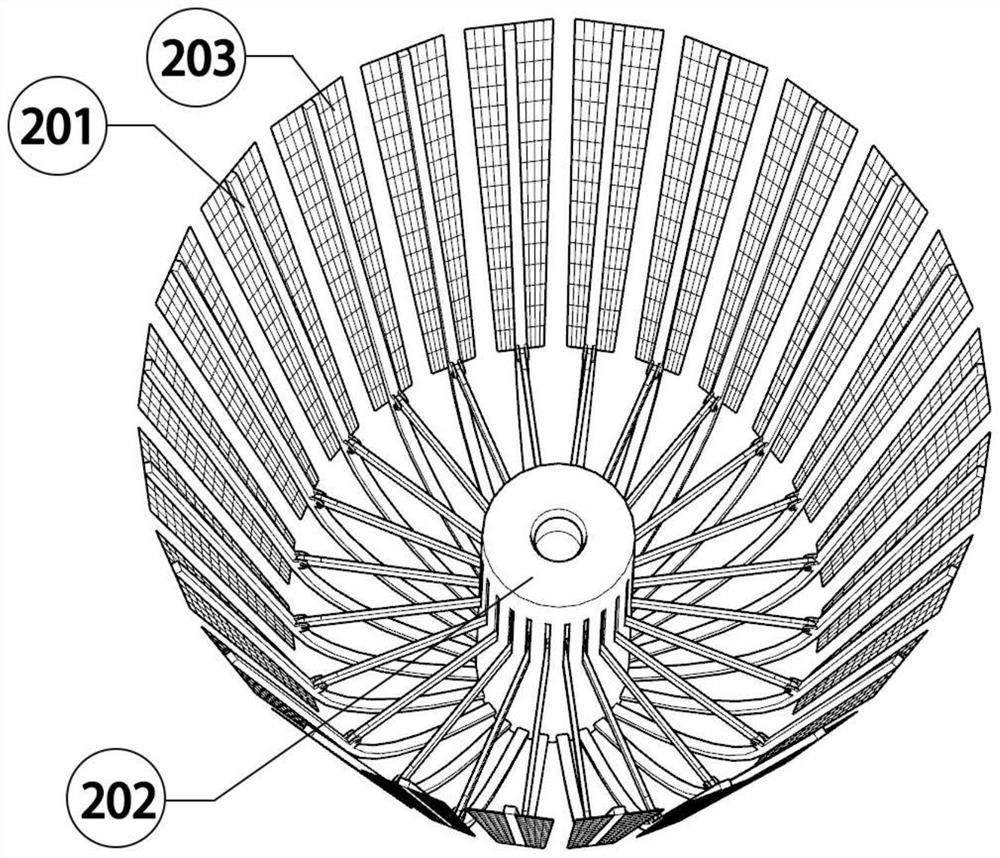

[0015] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A top connection module 1 of an elastic pile foundation resistant to frost heave damage is installed above the frost heave buffer module 2, and a gravity column module 3 is installed below the frost heave buffer module 2, and the support shaft 202 of the frost heave buffer module 2 A lifting plate 207 that can slide axially along the inside of the support shaft 202 is installed. The lifting plate 207 has an internal thread, and can cooperate with the external thread of the screw rod 104 to realize axial lifting. The edge of the lifting plate 207 is fixed. Shaft seat I 206, said shaft seat I 206 is axially connected with one end of support beam 204, and the other end of support beam 204 is axially connected with shaft seat II 205, said shaft seat II 205 is fixed on elastic buffer bar 201, said elastic buffer bar 201 A buffer net 203 is fixed on the top; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com