A Targeted Clean Extraction Method for Phosphorus Recovery from Sludge

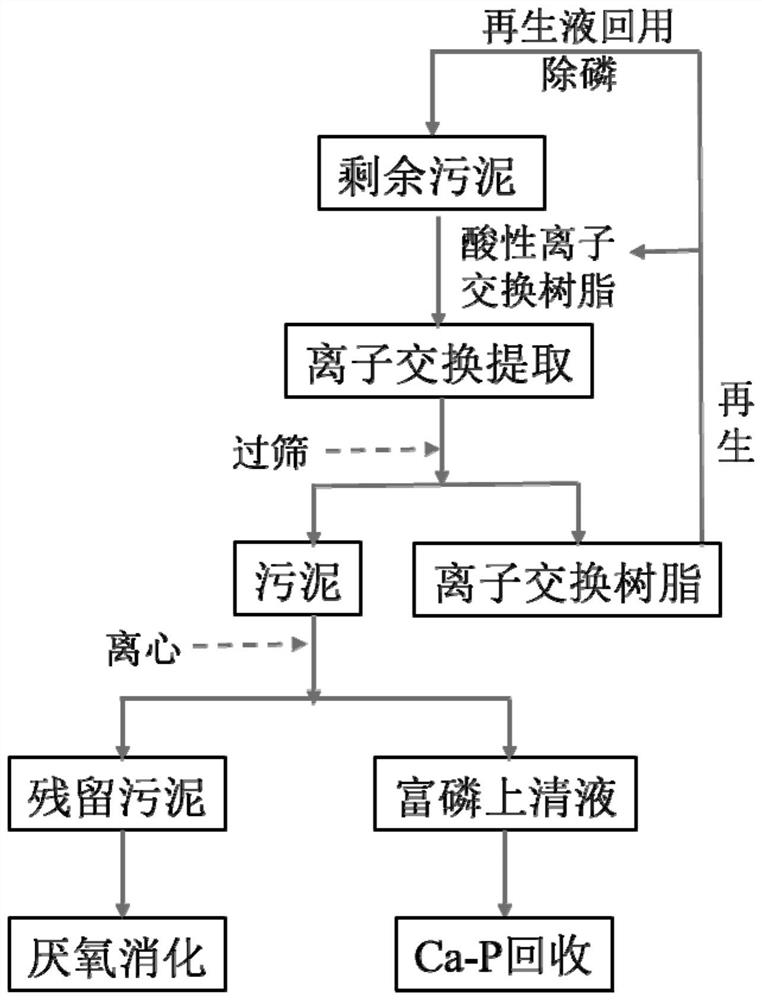

An extraction method and phosphorus recovery technology, applied in the field of sludge resource utilization, can solve the problems of low extraction efficiency of activated sludge, sludge can not be used directly as phosphate fertilizer, increase the complexity of phosphorus recovery process, etc., and achieve broad market application prospects, Important social and environmental benefits, the effect of little metal element interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The sludge used in this example is the residual activated sludge from biological phosphorus removal from Shanghai Bailonggang Sewage Treatment Plant, and its total solids (TS) and volatile solids (VS) are 2.45% and 1.47%, respectively, and the total phosphorus content is about 23.92mg / g TS, and the phosphorus content in the supernatant was about 40mg / L.

[0033] 1.225g of acidic ion exchange resin was added to 50g of sludge, which was shaken at 200rpm for 4h on a shaker at room temperature. After the reaction, the pH of the sludge dropped to 2.3. Use 55 mesh stainless steel sieve to obtain ion exchange resin and sludge respectively, carry out centrifugal filtration on the sludge, add calcium chloride to the filtrate to make the Ca / P molar ratio in the filtrate 1.5:1, and use 3M sodium hydroxide to adjust the pH to 9. Stir at 200 rpm for 30 minutes, stand for precipitation for 30 minutes, and recover phosphorus in the form of calcium phosphate precipitation. Finally, the...

Embodiment 2

[0039] The sludge used in this example is the residual activated sludge from biological phosphorus removal in a sewage treatment plant in Suzhou, where TS=2.40%, VS=1.56%, the total phosphorus content is about 24.64 mg / gTS, and the phosphorus content in the supernatant is about is 30mg / L.

[0040] Add 1.2g of acidic ion exchange resin to 50g of sludge, shake at 200rpm for 4h on a shaker at room temperature, and after the reaction ends, the pH of the sludge drops to 2. Use 55 mesh stainless steel sieve to obtain ion exchange resin and sludge respectively, carry out centrifugal filtration on the sludge, add calcium chloride to the filtrate to make the Ca / P molar ratio in the filtrate 1.5:1, and use 3M sodium hydroxide to adjust the pH to 9. Stir at 200 rpm for 30 minutes, stand for precipitation for 30 minutes, and recover phosphorus in the form of calcium phosphate precipitation. Finally, the used ion exchange resin is washed and regenerated with 5% hydrochloric acid.

Embodiment 3

[0045] The sludge used in this implementation is the mixed sludge of activated sludge for biological phosphorus removal from a sewage treatment plant in Suzhou and chemical sludge for enhanced phosphorus removal by iron salts, where TS=2.50%, VS=1.52%, and the total phosphorus content is about 24.50mg / g TS, the phosphorus content in the supernatant is about 35mg / L.

[0046] Add 1.25g of acidic ion exchange resin to 50g of sludge, shake at 200rpm for 4h on a shaker at room temperature, and after the reaction ends, the pH of the sludge drops to 2.5. Use 55 mesh stainless steel sieves to obtain ion exchange resin and sludge respectively, carry out centrifugal filtration on the sludge, add calcium chloride to the filtrate to make the Ca / P molar ratio in the filtrate 2:1, and use 3M sodium hydroxide to adjust the pH to 8. Stir at 200 rpm for 30 minutes, stand for precipitation for 30 minutes, and recover phosphorus in the form of calcium phosphate precipitation, and finally wash an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com