Functional compression towel block and manufacturing method thereof

A production method and functional technology, applied in the field of compressed towels, can solve the problems of complex process, uncontrollable molding size, and uncontrollable molding quality, and achieve the effect of simple process, guaranteed molding quality, and controllable molding size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

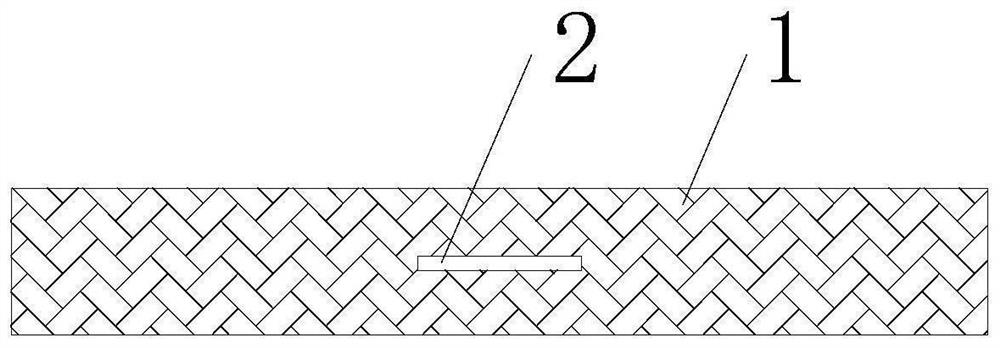

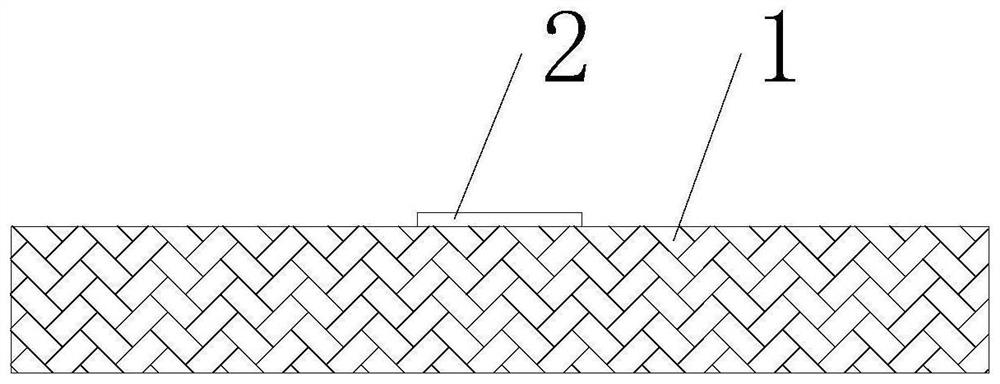

[0042] Embodiment 1, a method for making a functional compressed towel block of the present invention includes the following steps:

[0043] A. According to the required shape and size specifications, make a compressed towel block main body 1 of corresponding shape and size. The compressed towel block main body 1 can be circular, triangular, rectangular, polygonal, heart-shaped, star-shaped, animal-shaped, plant-shaped, etc.;

[0044] B. According to the required shape and size specifications, make a functional sheet 2 of corresponding shape and size. The shape of the functional sheet 2 can be circular, triangular, rectangular, polygonal, heart-shaped, star-shaped, animal-shaped, plant-shaped, etc.;

[0045] C. Pack the main body 1 of the compressed towel block and the functional sheet 2 that have been made separately.

[0046] The functional sheet 2 has one or more functions of fragrance, whitening, sterilization and disinfection, mosquito repellent, refreshment, skin care, s...

Embodiment 2

[0058] Embodiment 2, the difference between this embodiment and embodiment 1 is: the step C includes the following steps:

[0059] C21. Make packaging containers 3 of corresponding shapes and sizes according to the required shapes and sizes;

[0060] C22. Compress and mold the main body 1 of the compressed towel block according to the required shape and size;

[0061] C23. Set the prepared functional sheet 2 on the inner wall of the packaging container 3, and put the compressed towel block main body 1 after compression molding into the packaging container 3; The effect will slowly diffuse and penetrate into the main body 1 of the compressed towel block, so that the compressed towel block has functions such as fragrance;

[0062] The remaining parts are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0063] Embodiment 3, the difference between this embodiment and Embodiment 1 is that: the step C includes the following steps:

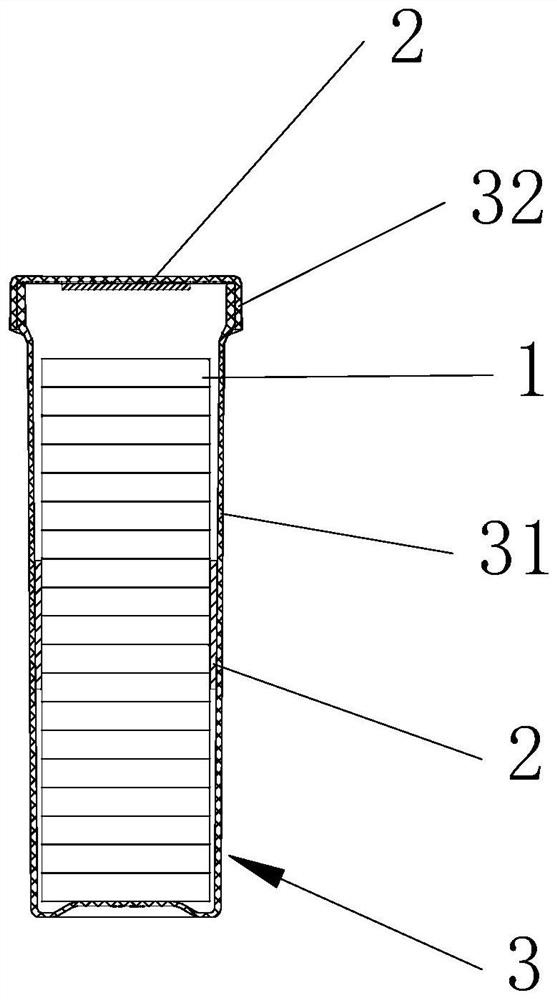

[0064] C31. Make packaging containers 3 of corresponding shapes and sizes according to the required shapes and sizes, such as image 3 As shown, the packaging container 3 includes a packaging storage body 31 and a packaging storage cover 32 covered on the packaging storage body 31. The packaging container 3 in this embodiment is a packaging bottle, and the packaging storage body 31 is a packaging bottle body. Accommodating cap 32 is a packaging bottle cap;

[0065] C32. Compress and mold the main body 1 of the compressed towel block according to the required shape and size;

[0066] C33. Set the prepared functional sheet 2 on the inner side wall of the packaging containing body 31 and / or on the inside of the packaging containing cover 32, and put the compressed towel block main body 1 after compression molding into the packaging containing body 31; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com