Packaging carton paperboard interlayer manufacturing and processing system

A processing system and cardboard technology, applied to cardboard items, etc., can solve the problems of waste of manpower and material resources, recessed cutting position, unfavorable batch production, etc., to achieve the effect of saving manpower and material resources, ensuring the strength of support and connection, and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

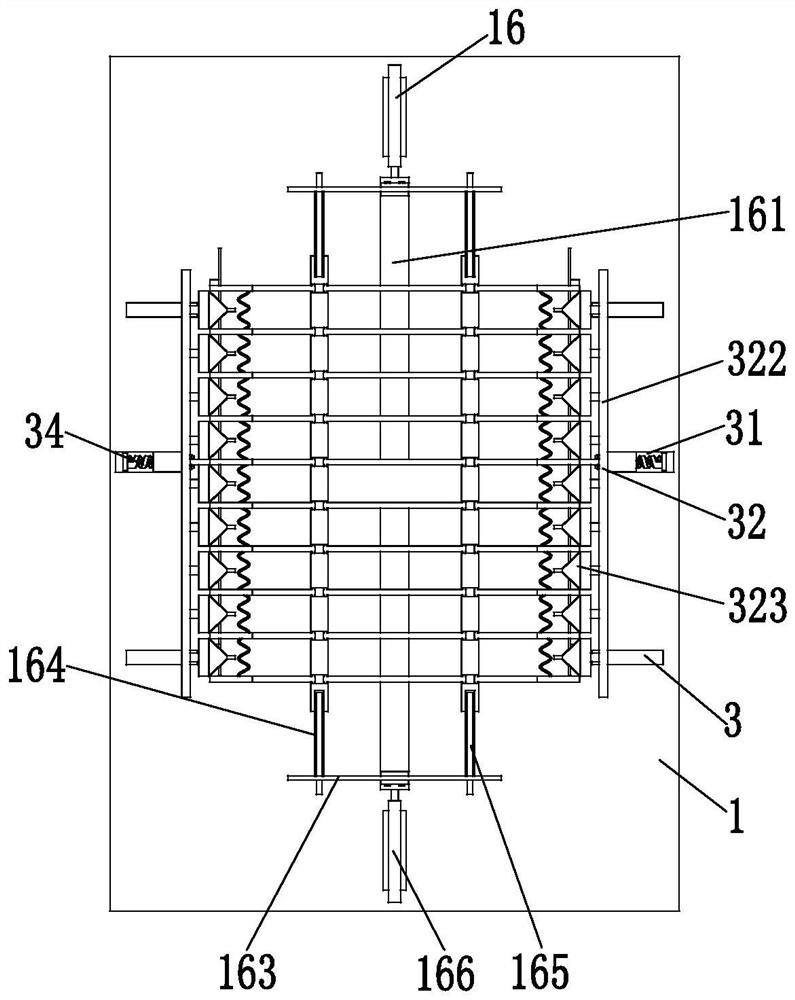

[0031] Such as Figure 1 to Figure 7 As shown, a packaging carton cardboard interlayer production and processing system includes a fixed base 1, a fixed frame 2 and a positioning mechanism 3, and the left and right sides of the lower end surface of the fixed base 1 are symmetrically fixed with fixed frames 2, and the fixed base 1 A positioning mechanism 3 is provided.

[0032]The fixed base 1 includes an installation base plate 11, a chute 12, a clamping plate 13, a cutting groove 14, a pressure-holding spring 15 and a cutting unit 16, and the front and rear sides of the upper end surface of the installation base plate 11 are symmetrically provided with chute 12, A clamping plate 13 is evenly slid in the chute 12, and cutting grooves 14 are symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com