Spiral milling actuator

An actuator and helical milling technology, which is applied in the field of automatic hole making in aircraft digital assembly, can solve the problems of composite material processing layering and large tool loss, achieve high-efficiency automatic hole making, avoid process defects, and ensure the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

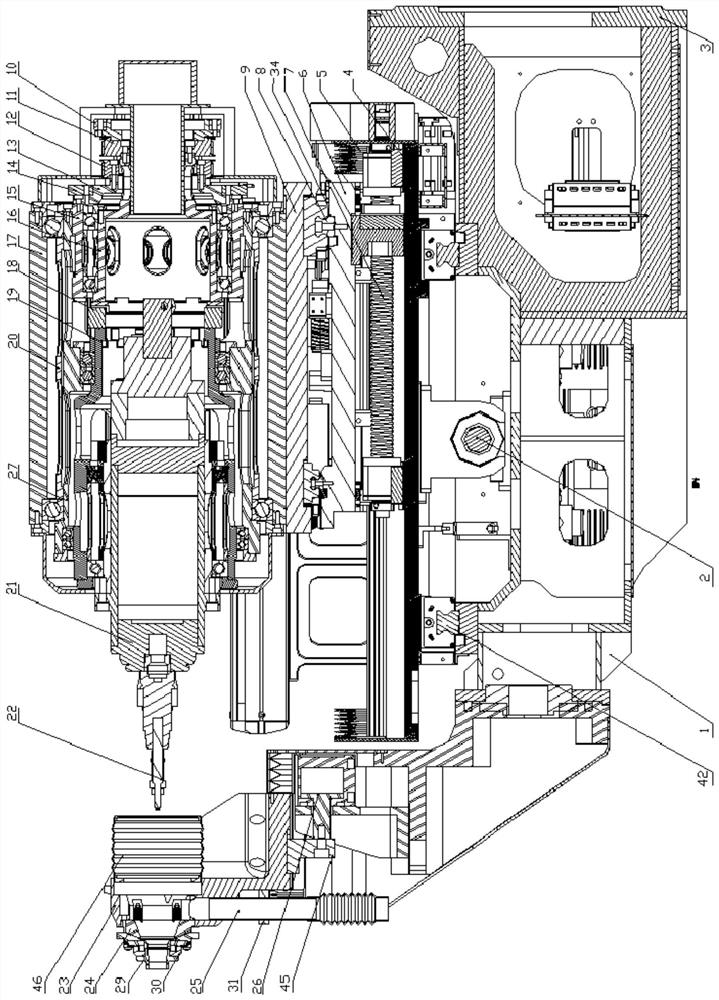

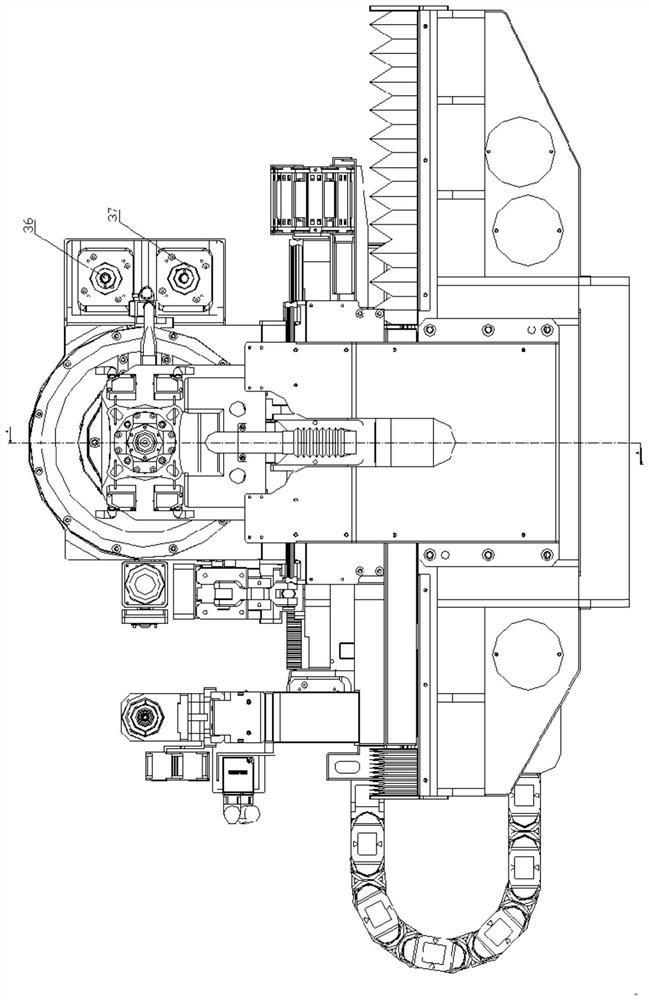

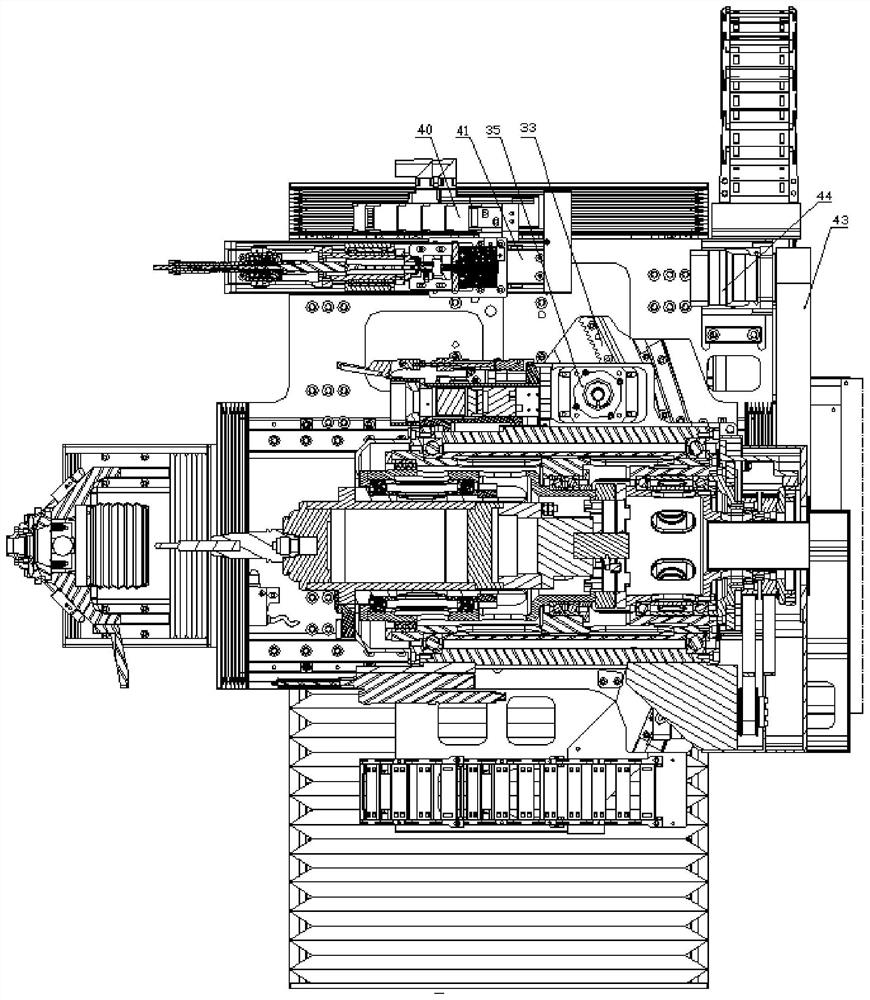

[0042] Such as figure 1 As shown, the helical milling actuator includes: a base 1 and a cutter 22;

[0043] The feeding mechanism is placed on the base 1 and is used to drive the cutter 22 to perform feeding motion;

[0044] The swing mechanism is placed on the feed mechanism and is used to drive the cutter 22 to swing in an arc;

[0045] The eccentric adjustment mechanism is used to control the radial offset distance of the tool 22, including an inner eccentric sleeve 19, an inner shaft cylinder 16 connected to the inner eccentric sleeve 19 through a sliding connection, and an outer sleeve placed outside the inner eccentric sleeve 19. Eccentric sleeve 27, the outer shaft cylinder 15 that is fixed with outer eccentric sleeve 27; Figure 5 and Figure 6 As shown, the axis of the inner and outer contours of the inner eccentric sleeve 19 and the outer eccentric sleeve 27 adopts an offset design, and the sliding connection adopts the Oldham coupling 18;

[0046] The rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com