Laser cutting device and cutting method for profiled bar

A technology of laser cutting and laser cutting head, which is applied in the direction of laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of poor edge quality of laser processing, difficulty in variable section cutting, deep groove cutting interference, etc., and achieve processing efficiency , avoid hanging slag, and achieve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

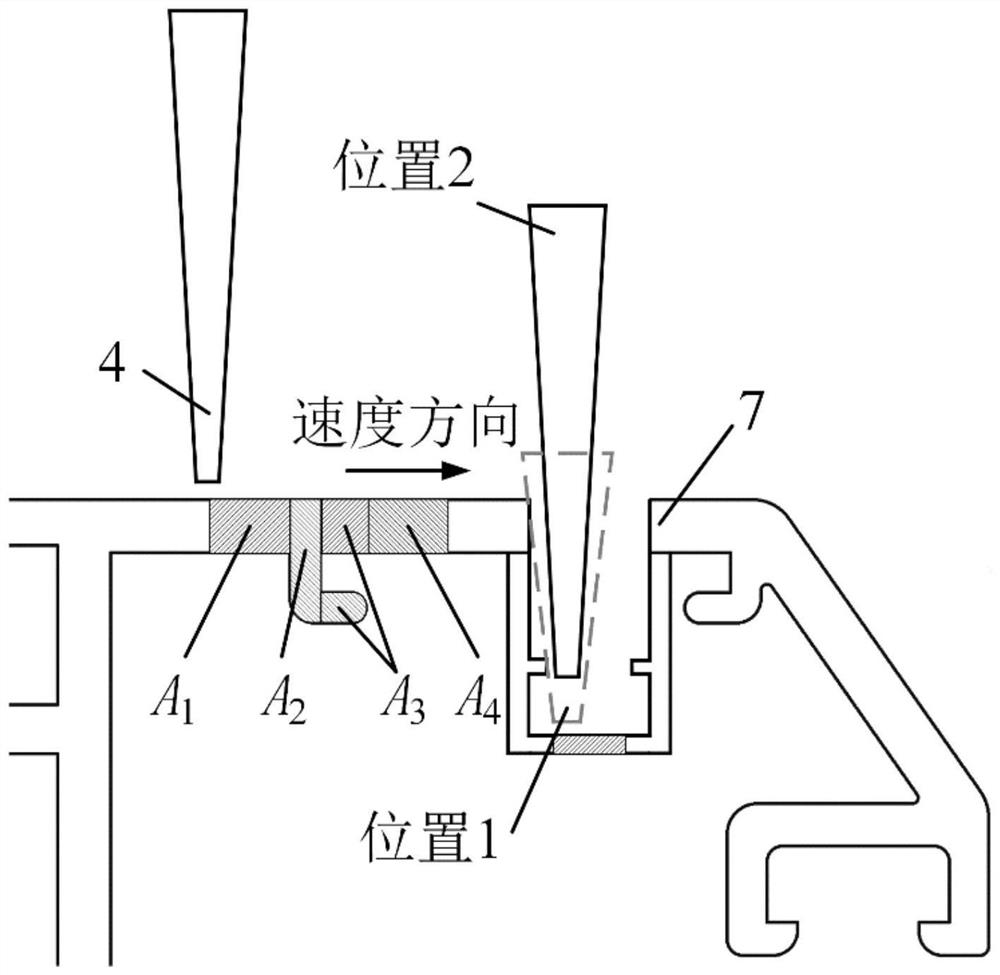

[0035] The following is attached Figure 1-3 Specific embodiments of the present invention are described in detail.

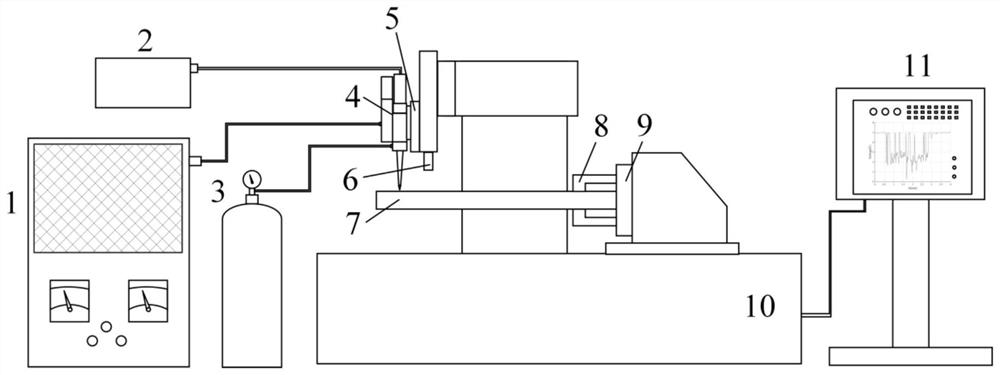

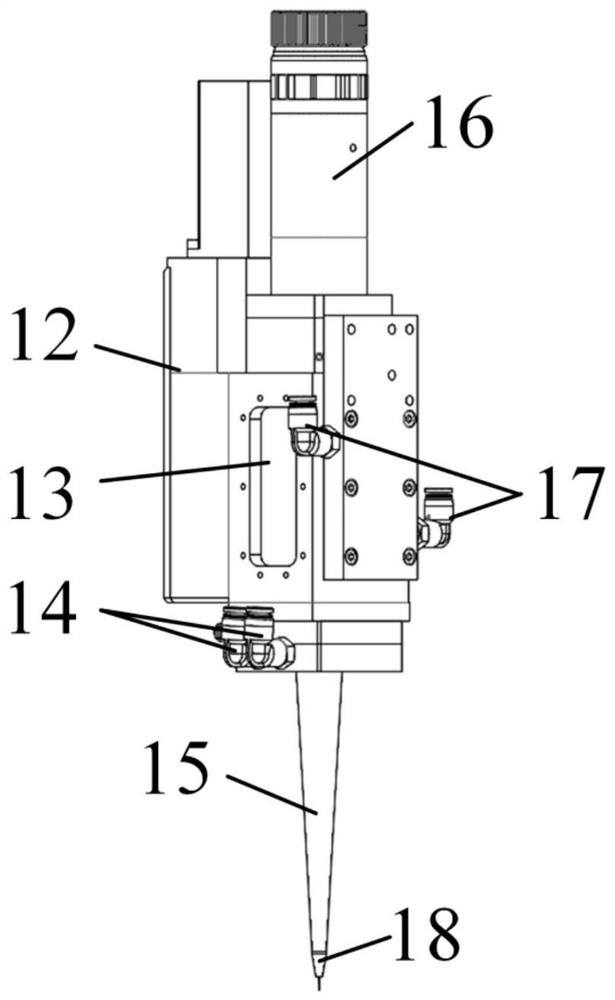

[0036] Such as Figure 1-2 As shown, this embodiment provides a special-shaped material laser cutting device, including a chiller 1, a laser 2, an air source 3, a laser cutting head 4, a laser cutting head fast-forward shaft 5, a scanning lens 6, a special-shaped material clamp 8, An ultrasonic auxiliary generating device 9 , a machine bed 10 , and a control panel 11 .

[0037] Among them: the chiller 1 is connected to the laser cutting head 4 through a waterway to cool the lens of the laser cutting head and prevent the lens from fogging; the laser 2 is connected to the laser cutting head 4 through an optical fiber to provide a laser light source for laser cutting; the air source 3 can be provided by an air tank or Provided by an air pump, it is connected to the laser cutting head 4 through a pipeline to blow away slag and protect the lens during laser cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com