On-line circulating dialysis device and method for hydraulic oil of gas pocket in steelmaking production

A technology of dialysis device and hydraulic device, which is applied in the direction of separation method, chemical instrument and method, feeding/discharging device of settling tank, etc., can solve problems such as inability to recycle waste engine oil, time-consuming and labor-intensive replacement, and delay in production, etc., to achieve The effect of protecting the service life of equipment, reducing production costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

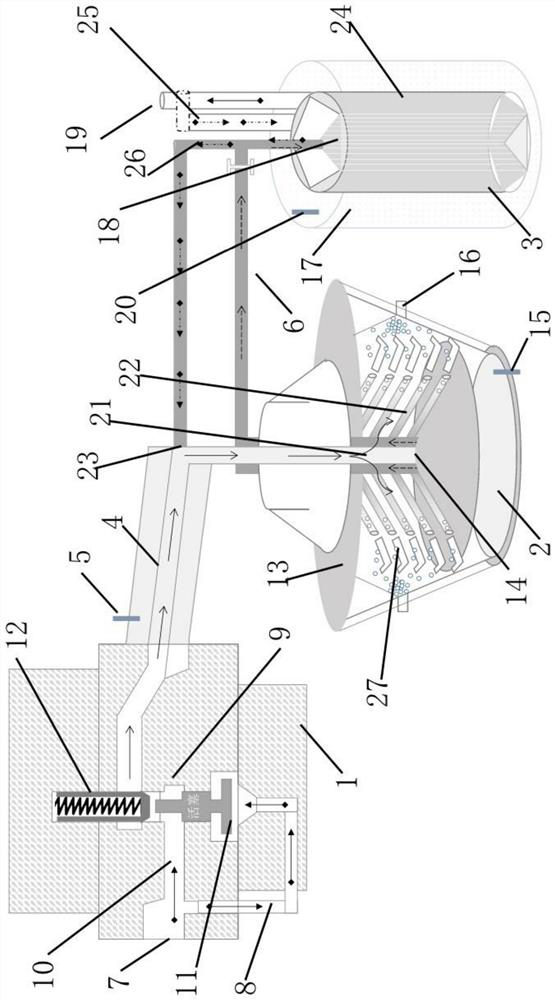

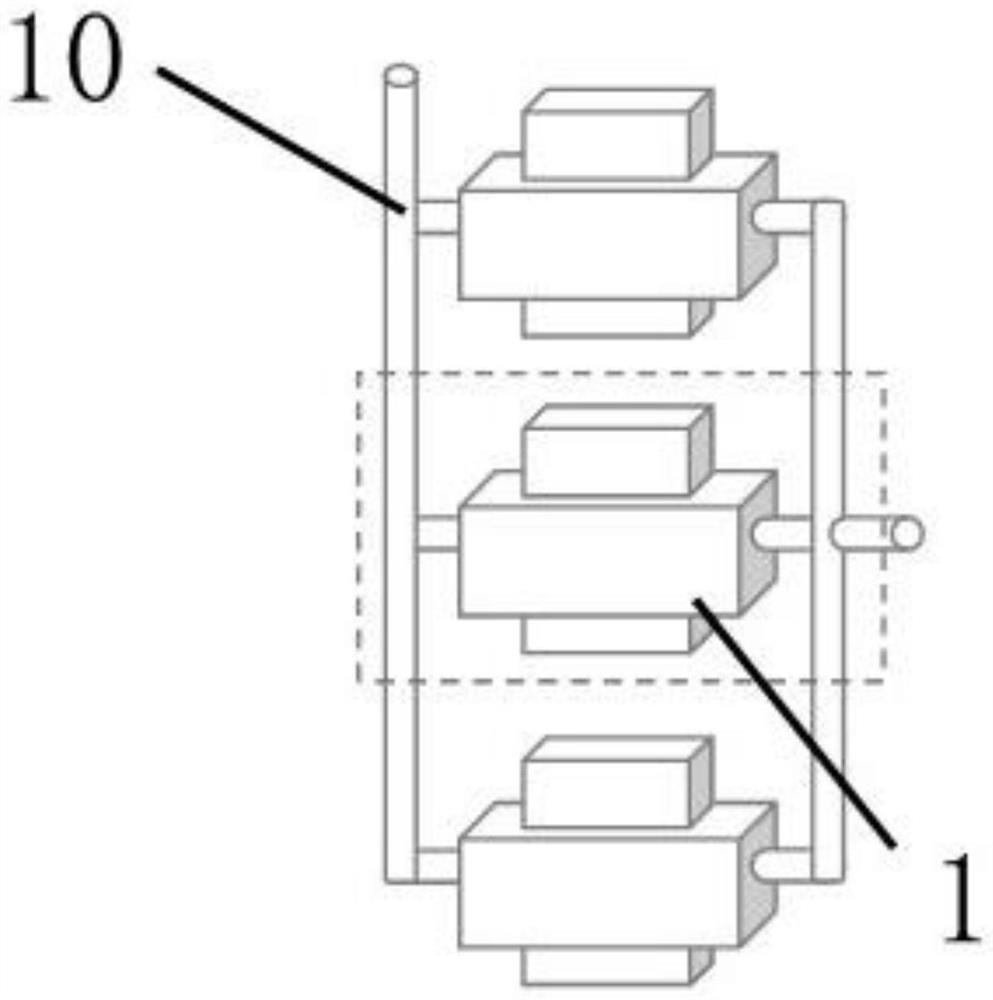

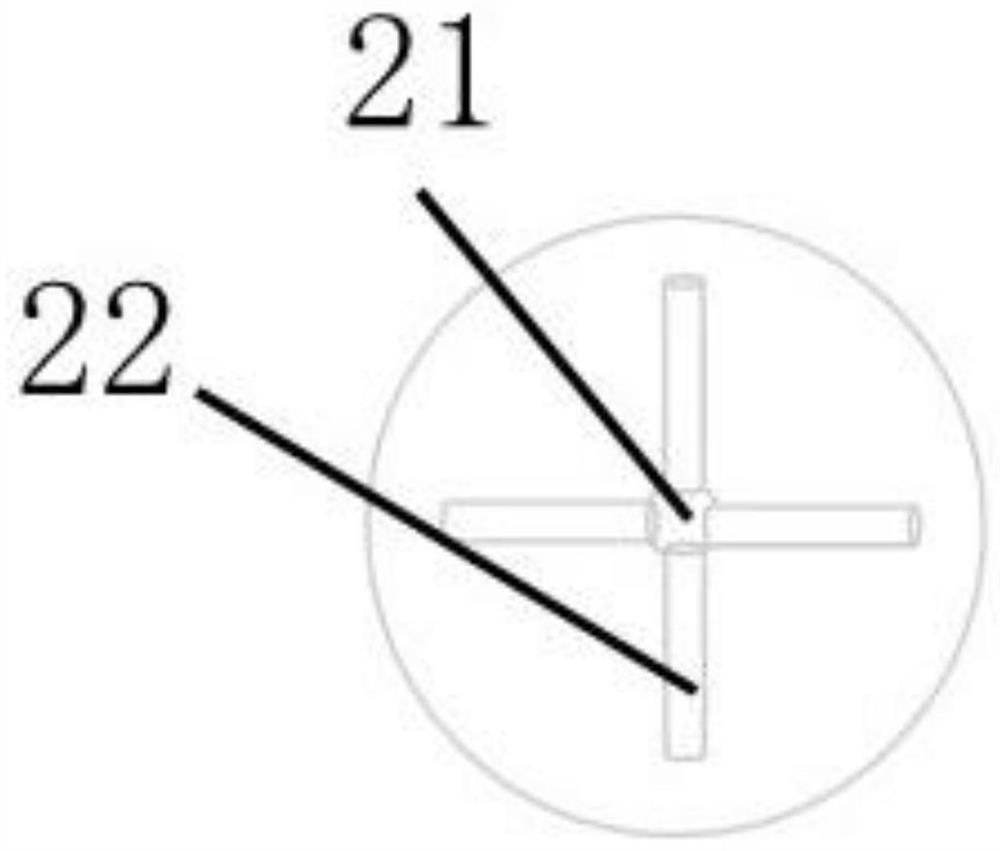

[0028] Such as figure 1 , figure 2 and image 3 As shown, an online circulation dialysis device for gas-laden hydraulic oil in steelmaking production includes an oil inlet control device 1, an online oil liquid dialysis device 2 and a staggered filter cartridge device 3, and the oil inlet control device 1 and the online The oil dialysis device 2 is connected through a steam heating pipeline 4, the steam heating pipeline 4 is provided with a steam injection port 5, and the online oil dialysis device 2 is connected to the split-layer filter cartridge device through a discharge pipeline 6 3 connection, the oil inlet control device 1 includes an oil inlet 7, a control oil circuit 8 and a plurality of hydraulic devices 9, the oil inlet 7 is connected to the hydraulic device 9 through an oil inlet pipeline 10, and the control oil circuit 8 Control the activity of the hydraulic device 9, the hydraulic device 9 includes a piston 11 and an adjustment spring 12, the control oil circu...

Embodiment 2

[0037] The present embodiment adopts the method for on-line circulation dialysis of the hydraulic oil in the steelmaking gas drum produced by the device provided in Embodiment 1, comprising the following steps:

[0038] S1: The oil to be regenerated enters one or more hydraulic devices 9 through the oil inlet 7 of the oil inlet control device 1, and then enters the steam heating pipeline 4 through the hydraulic device 9, and passes through the steam injection port 5 in the steam heating pipeline 4 Inject steam to raise the temperature of the oil in the steam heating pipeline 4 to 40°C-60°C, and then the oil to be regenerated passes through the feed port 23 and enters the centrifugal shaft 21 of the line circulating oil dialysis device 2 ;

[0039] S2: The centrifugal mechanism 14 rotates and controls the rotational speed at 25,000r / min to 30,000r / min, quickly centrifugally disperses the oil to be regenerated in the centrifugal shaft into the dispersion pipelines 22 of each lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com