Cable coiling machine

A coiling machine and cable technology, applied in the direction of thin material processing, tobacco, tobacco processing, etc., can solve the problems of looseness between cables and wires, damage to electrical performance, and inability to guarantee the degree of bending of cables, so as to ensure the degree of bending and flatness, The effect of protecting electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

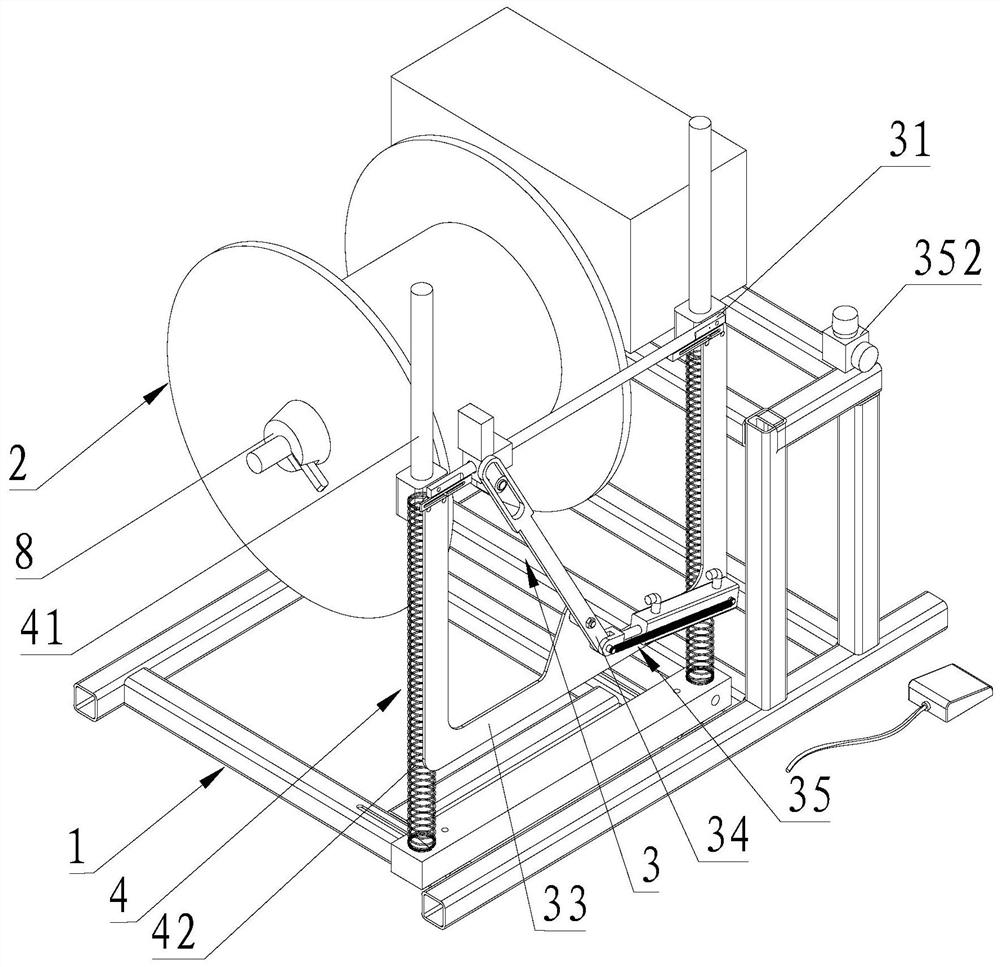

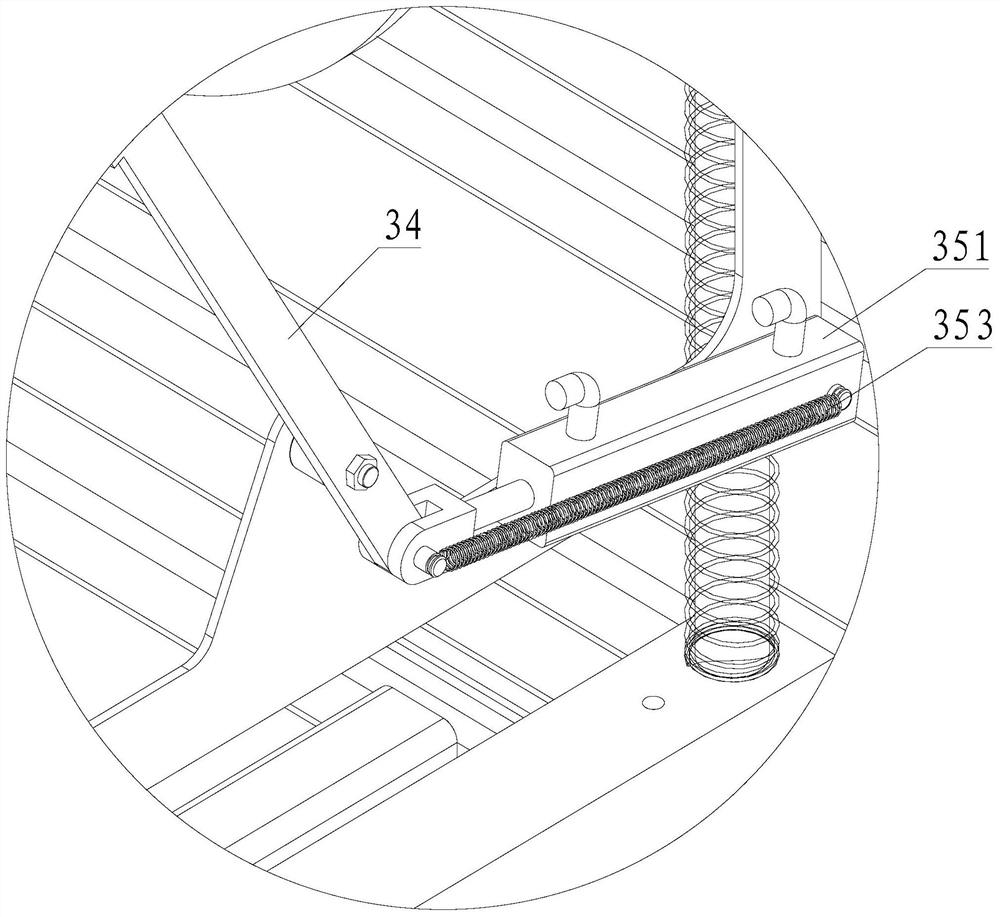

[0034] Please refer to Figure 1 to Figure 4 As shown, a cable winding machine provided by the present invention includes a roller for winding a cable and a booster device arranged on one side of the roller; the booster device is configured to wind the cable from one end of the roller to the other end. At this time, a force is exerted on the cable from the other end of the roller to one end.

[0035] It can be seen from the above description that the beneficial effects of the present invention are: to provide a cable coiling machine, which generates a force opposite to the cable winding direction on the cable through the assisting device, so that the cables are always in close contact with each other during the winding process, forming a tight The arrangement e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com