A cable winding machine

A coiling machine and cable technology, applied in the direction of thin material processing, tobacco, tobacco processing, etc., can solve the problems of looseness between cables and wires, damage to electrical performance, and inability to guarantee the degree of bending of cables, so as to ensure the degree of bending and flatness, The effect of protecting electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

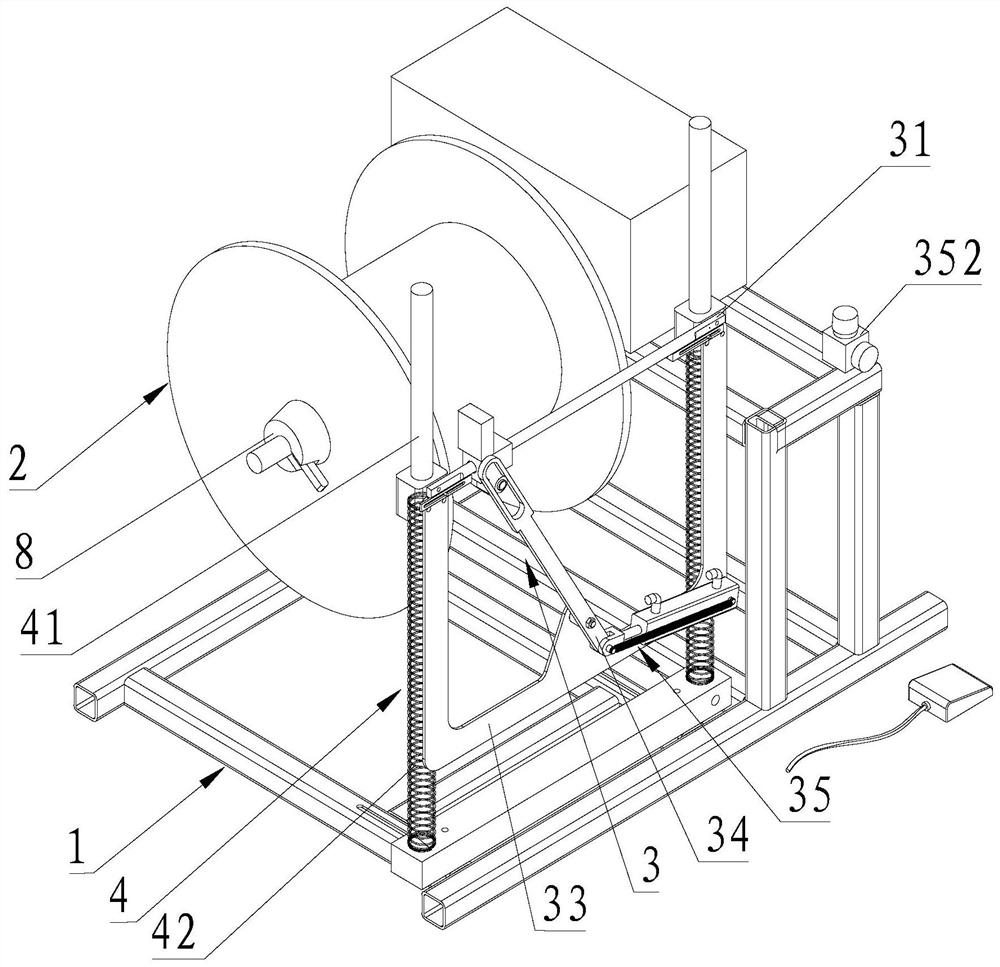

[0036] Further, the power assist device includes a swing mechanism, which is parallel to the direction of the connecting line from one end to the other end of the roller.

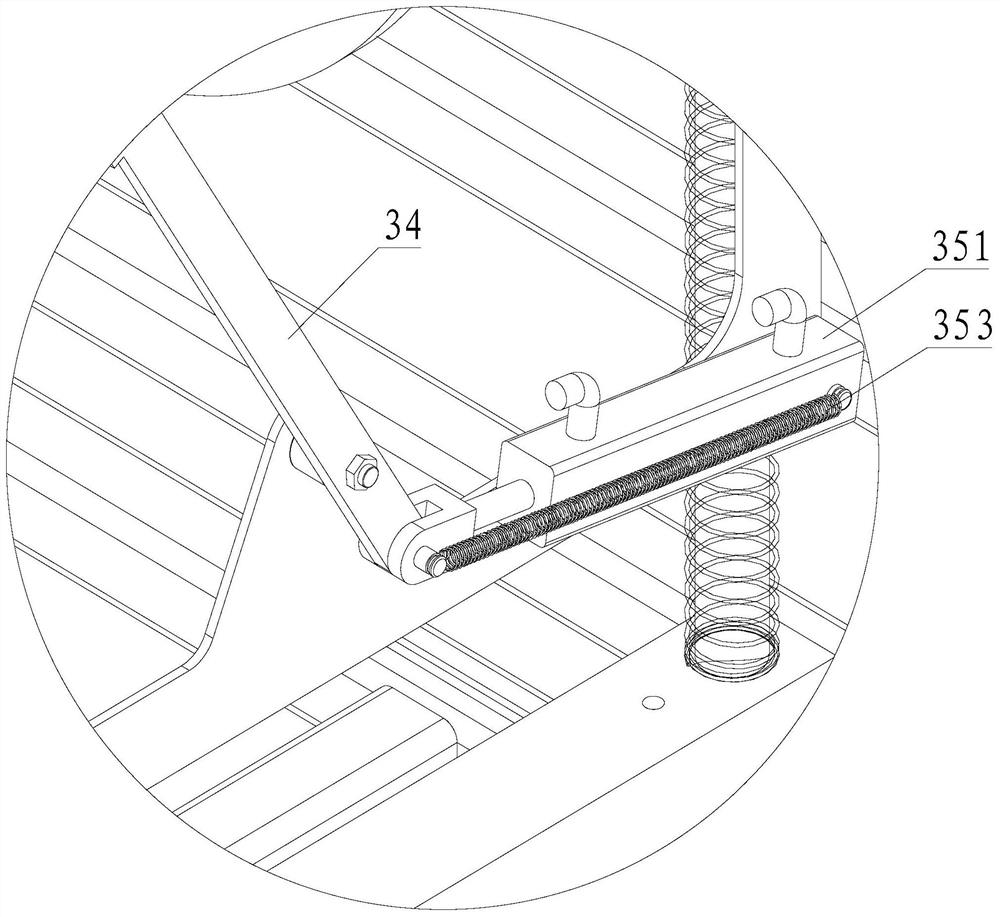

[0038] Further, the swing mechanism includes a U-shaped swing rod bracket, a swing rod and a drive mechanism;

[0043] Further, the U-shaped bottom side wall corresponding to the pendulum support is provided with a bump;

[0045] The middle of the swing rod is hinged with the projection;

[0052] Further, the driving mechanism also includes an air pressure regulating valve, and the air pressure regulating valve is connected with the cylinder.

[0053] From the above description, it can be known that the movement of the cylinder through the air pressure adjusts the valve hole.

[0055] The direction of the connecting line from one end to the other end of the roller is in the horizontal direction, and the power assist device is arranged on the sliding rod

[0056] It can be seen from the above description that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com