Tea leaf wrapping-kneading machine and tea leaf wrapping-kneading method

A technology of tea bags and tea leaves, which is applied in tea processing before extraction, etc., can solve problems such as difficulty in ensuring stable product quality, low work efficiency, and low cleanliness of tea bag kneading process, so as to save the operation of fast bag unpacking, Improved work efficiency and ease of processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

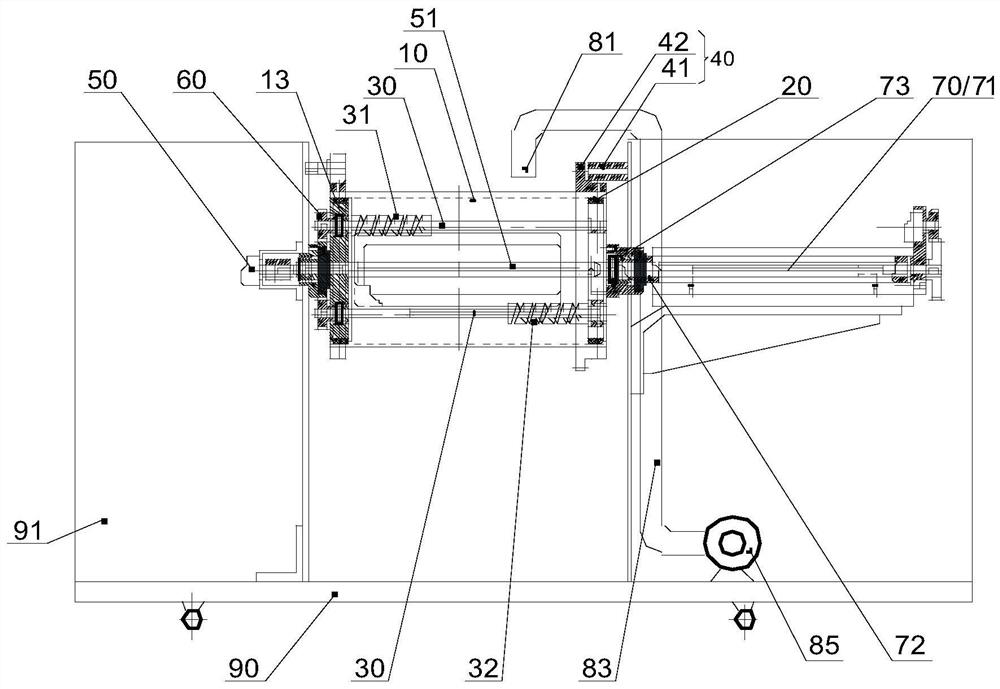

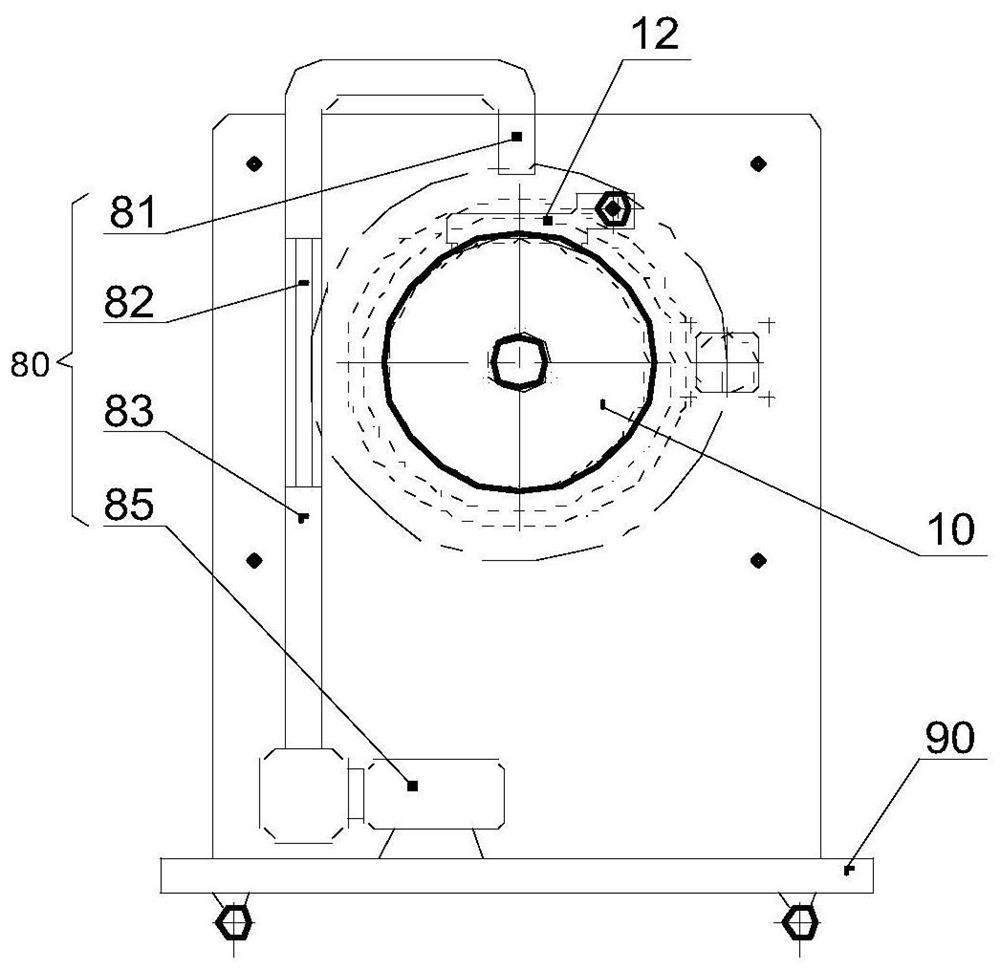

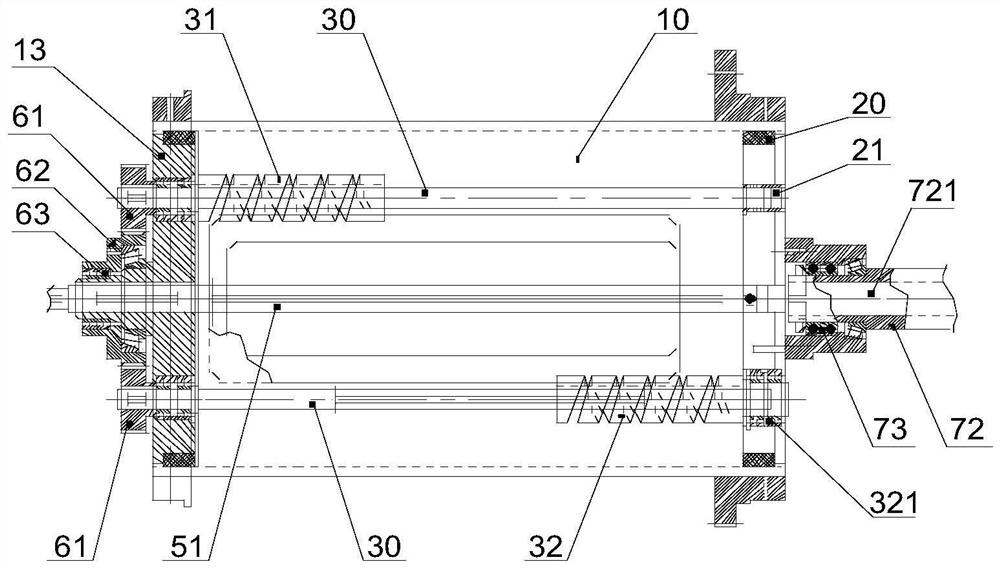

[0054] The invention provides a tea bag kneading machine, such as figure 1 and image 3As shown, the tea bag kneading machine includes a barrel 10, a side kneading disc 20 and at least one stirring rod 30 pierced in the barrel 10; the barrel 10 is horizontally arranged and connected to a first drive mechanism 40, and the first drive mechanism 40 Used to drive the barrel 10 to rotate; the side kneading disc 20 is movably arranged in the barrel 10 and connected to the translation drive mechanism 70, and the translation drive mechanism 70 is used to drive the side kneading disc 20 to translate in the barrel 10; the stirring rod 30 is connected to The second driving mechanism 50 , the second driving mechanism 50 is used to drive the stirring rod 30 to rotate around the axis of the barrel 10 in the barrel 10 .

[0055] In the tea bag kneading machine, the barrel 10 rotates, and the stirring rod 30 rotates in the barrel 10 to drive the tea leaves to roll in the barrel 10 . During ...

Embodiment 2

[0075] The invention provides a tea bag kneading method, such as Figure 8 As shown, the tea bag kneading method includes: step S10, putting the tea leaves into the barrel 10; step S20, kneading the tea leaves from one end of the barrel 10 to the other end, and during the kneading process, driving the tea leaves Tumbling in the barrel 10; step S30, keep the kneading pressure for a period of time; step S40, remove the kneading pressure, and drive the tea leaves to tumble in the barrel 10.

[0076] In the tea bag kneading method, step S20 is to knead the tea leaves, step S30 is to keep the pressure according to the pressure holding time, and step S40 is to break up the tea leaves, which saves the operation of using a cloth bag to tightly pack the tea leaves. On the one hand, the cleanliness is improved, and the The hygienic conditions are improved; on the other hand, the operation of quick packing and unpacking is omitted, manual operation is reduced, and work efficiency is impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com