Use method and application of natural antioxidant

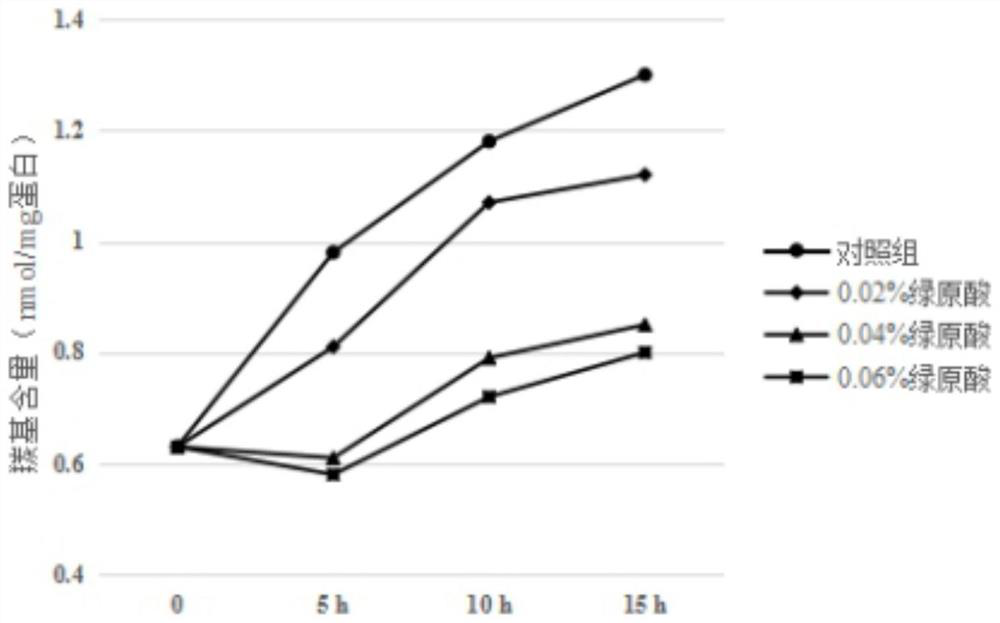

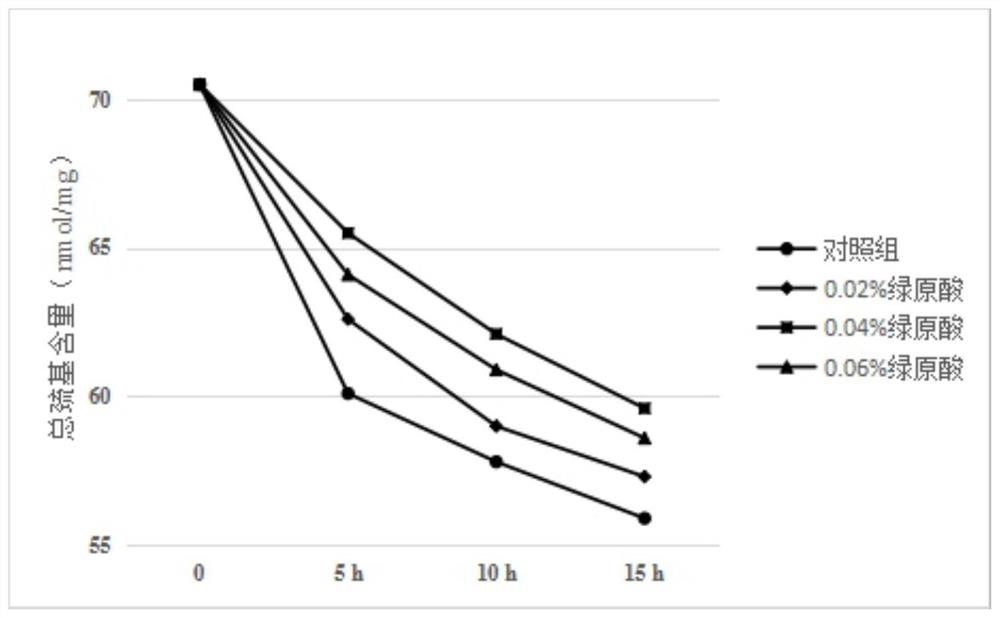

A natural antioxidant, myofibrillar protein technology, applied in the direction of food ingredients as antioxidants, application, preservation of meat/fish with chemicals, etc. Inhibiting protein oxidation process, retaining color and flavor, and anti-oxidative free radicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Preparation of minced beef

[0021] Take the longest muscle of the back of the beef and chop it, add 5% salt, 20% ice water and 20% fat to the chopping machine. After chopping and mixing is completed, take 500g of minced meat and perform blank chopping and mixing for 5 minutes.

[0022] (2) Extraction of myofibrillar protein

[0023] Get prepared ground beef 1.5g, add 4 times the volume of myofibrillar protein extract (10mmol / LK 2 HPO 4 , 100mmol / LNaCl, 2mmol / LMgCl 2 , 1 mmol / L EGTA, pH 7.0). Homogenize at 4°C for 1 min at 8,000 r / min, centrifuge for 10 min at 1,000×g, and collect the precipitate. Repeat 3 times. Add 5 times the volume of 100mmol / L NaCl eluent to the precipitate, and then homogenize for 1min at a speed of 8000r / min. The homogenate was centrifuged for 10 min at a speed of 1000 × g, and the precipitate was collected and repeated 3 times.

[0024] (3) Preparation of myofibrillar protein solution

[0025] Use 20mmol / L pH 6.0 phosphate buffer so...

Embodiment 2

[0029] (1) Preparation of minced beef

[0030] Take the longest muscle of the back of the beef and chop it, add 5% salt, 20% ice water and 20% fat to the chopping machine. After chopping and mixing is completed, take 500g of minced meat and perform blank chopping and mixing for 5 minutes.

[0031] (2) Extraction of myofibrillar protein

[0032] Get prepared ground beef 1.5g, add 4 times the volume of myofibrillar protein extract (10mmol / LK 2 HPO 4 , 100mmol / LNaCl, 2mmol / LMgCl 2 , 1 mmol / L EGTA, pH 7.0). Homogenize at 4°C for 1 min at 8,000 r / min, centrifuge for 10 min at 1,000×g, and collect the precipitate. Repeat 3 times. Add 5 times the volume of 100mmol / L NaCl eluent to the precipitate, and then homogenize for 1min at a speed of 8000r / min. The homogenate was centrifuged for 10 min at a speed of 1000 × g, and the precipitate was collected and repeated 3 times.

[0033] (3) Preparation of myofibrillar protein solution

[0034] Use 20mmol / L pH 6.0 phosphate buffer so...

Embodiment 3

[0038] (1) Preparation of minced beef

[0039] Take the longest muscle of the back of the beef and chop it, add 5% salt, 20% ice water and 20% fat to the chopping machine. After chopping and mixing is completed, take 500g of minced meat and perform blank chopping and mixing for 5 minutes.

[0040] (2) Extraction of myofibrillar protein

[0041] Get prepared ground beef 1.5g, add 4 times the volume of myofibrillar protein extract (10mmol / LK 2 HPO 4 , 100mmol / LNaCl, 2mmol / LMgCl 2 , 1 mmol / L EGTA, pH 7.0). Homogenize at 4°C for 1 min at 8,000 r / min, centrifuge for 10 min at 1,000×g, and collect the precipitate. Repeat 3 times. Add 5 times the volume of 100mmol / L NaCl eluent to the precipitate, and then homogenize for 1min at a speed of 8000r / min. The homogenate was centrifuged for 10 min at a speed of 1000 × g, and the precipitate was collected and repeated 3 times.

[0042] (3) Preparation of myofibrillar protein solution

[0043] Use 20mmol / L pH 6.0 phosphate buffer so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com