Bread making equipment for promoting starch digestion of wheat bread and working method of bread making equipment

A bread and starch technology, which is applied in the fields of dough homogenization, baking, food science, etc., can solve the problems of low rounding efficiency, difficult to use in batches, cumbersome steps, etc., to reduce the volume, facilitate purchase and use, and enhance the rounding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

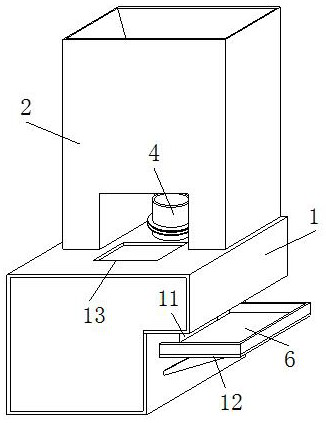

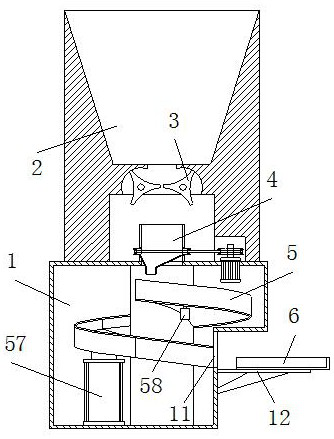

[0031] as attached figure 1 and 2 As shown, a kind of bread making equipment that promotes the digestion of wheat bread starch includes a frame 1, a distribution wheel 3, a feed pipe 4 and a rounding frame 5.

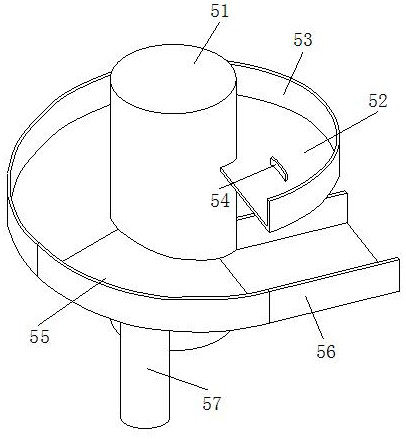

[0032] as attached figure 2 As shown, the upper surface of the frame 1 is provided with a downwardly recessed hopper 2, the hopper 2 is used to place the dough to be fermented, and the two distribution wheels 3 are symmetrically arranged below the discharge port of the hopper 2, and the distribution wheels 3 They are all three-pointed star structures. The distributing wheel 3 is used to divide the dough. During operation, the two distributing wheels 3 can be synchronously rotated in opposite directions through the motor, and the dough falling from the outlet can be extruded and cut to divide the dough. Form several small doughs of equal volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com