Chain harrow type residual film picking mechanism and rotary tillage and residual film recovery all-in-one machine

A residual film recovery, integrated machine technology, applied in agricultural machinery and implements, collectors, solid separation and other directions, can solve the problems of increasing downtime and maintenance time and cost, inconvenient processing and recycling, affecting recycling efficiency, etc., to reduce The effect of separating debris, improving recycling efficiency, and reducing downtime and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

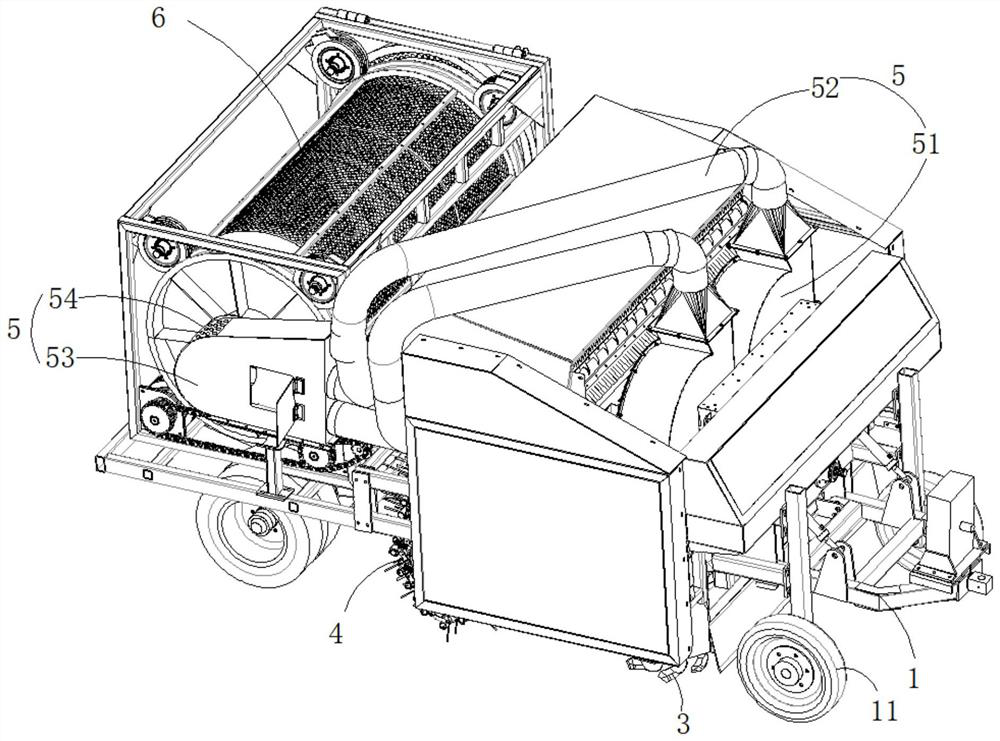

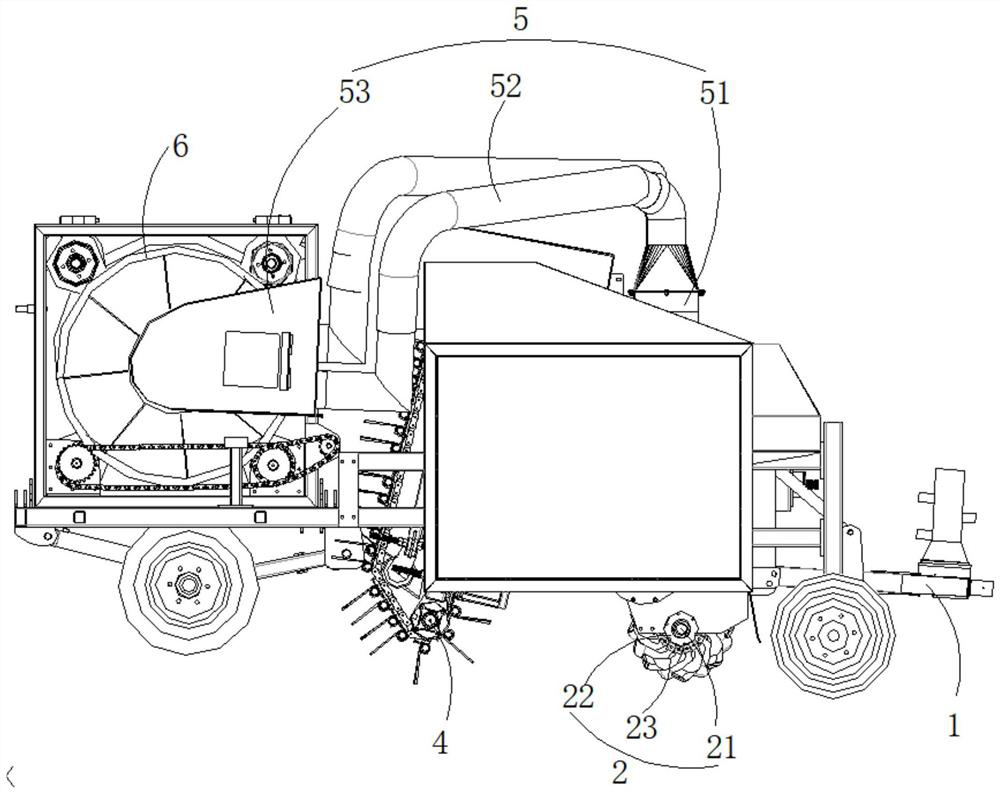

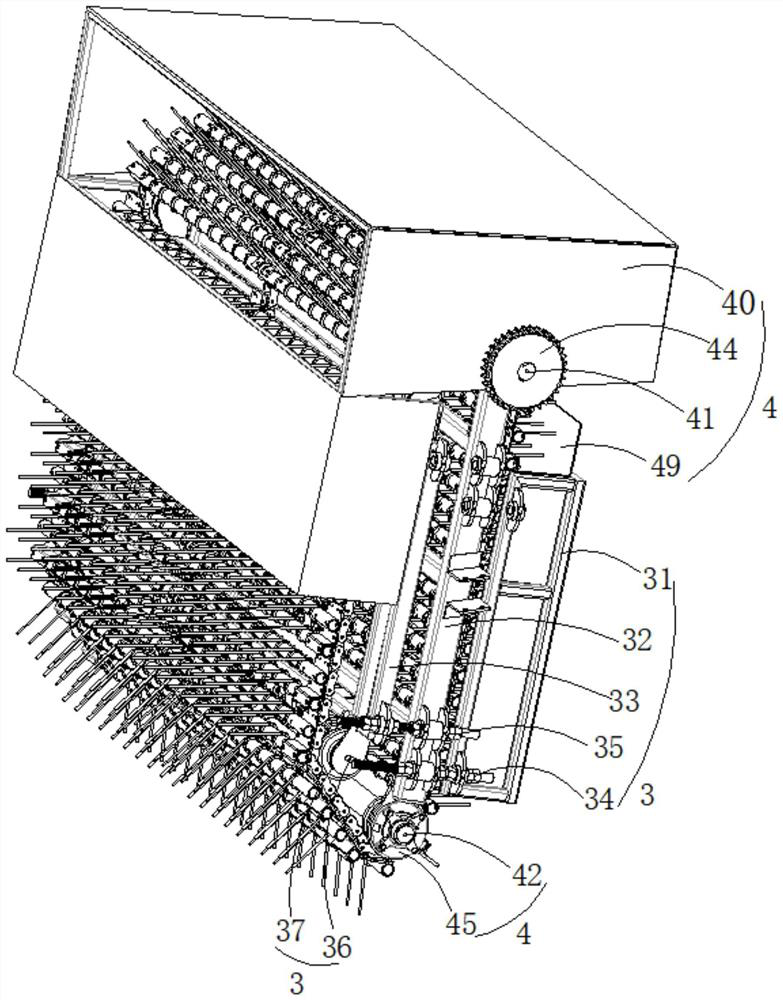

[0030] Such as Figure 1 to Figure 7 Shown:

[0031] In the chain rake type residual film picking mechanism part of this embodiment, the chain rake type residual film picking mechanism 4 includes a driving wheel shaft 41 and a driven wheel shaft 42, and the two ends of the two telescopic brackets 32 pass through the driving wheel shaft 41 and the driven wheel shaft respectively. The driving wheel shaft 42 is connected in a rectangular shape, and the two ends of the driving wheel shaft 41 are equipped with a driving wheel 43 and a transmission sprocket 44 respectively, and the two ends of the driven wheel shaft 42 are equipped with a driven wheel 45 respectively, and are fitted and connected to the driving wheel 43 and the driven wheel 45 Between the endless transmission chain 46, and the tensioning wheel 37 fits in the transmission chain 46 inner side, several horizontal plates 47 are connected between the two transmission chains 46, and each horizontal plate 47 is provided wi...

Embodiment 2

[0040] Such as Figure 1 to Figure 7 Shown:

[0041] In the chain rake type residual film picking mechanism part of this embodiment, the chain rake type residual film picking mechanism 4 includes a driving wheel shaft 41 and a driven wheel shaft 42, and the two ends of the two telescopic brackets 32 pass through the driving wheel shaft 41 and the driven wheel shaft respectively. The driving wheel shaft 42 is connected in a rectangular shape, and the two ends of the driving wheel shaft 41 are equipped with a driving wheel 43 and a transmission sprocket 44 respectively, and the two ends of the driven wheel shaft 42 are equipped with a driven wheel 45 respectively, and are fitted and connected to the driving wheel 43 and the driven wheel 45 Between the endless transmission chain 46, and the tensioning wheel 37 fits in the transmission chain 46 inner side, several horizontal plates 47 are connected between the two transmission chains 46, and each horizontal plate 47 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com