Projection ray machine

A technology of projection light machine and projection lens, which is applied in the direction of optics, instruments, projection devices, etc., and can solve the problems of poor heat dissipation, reduced projection quality of projection light machine, and difficulty in effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

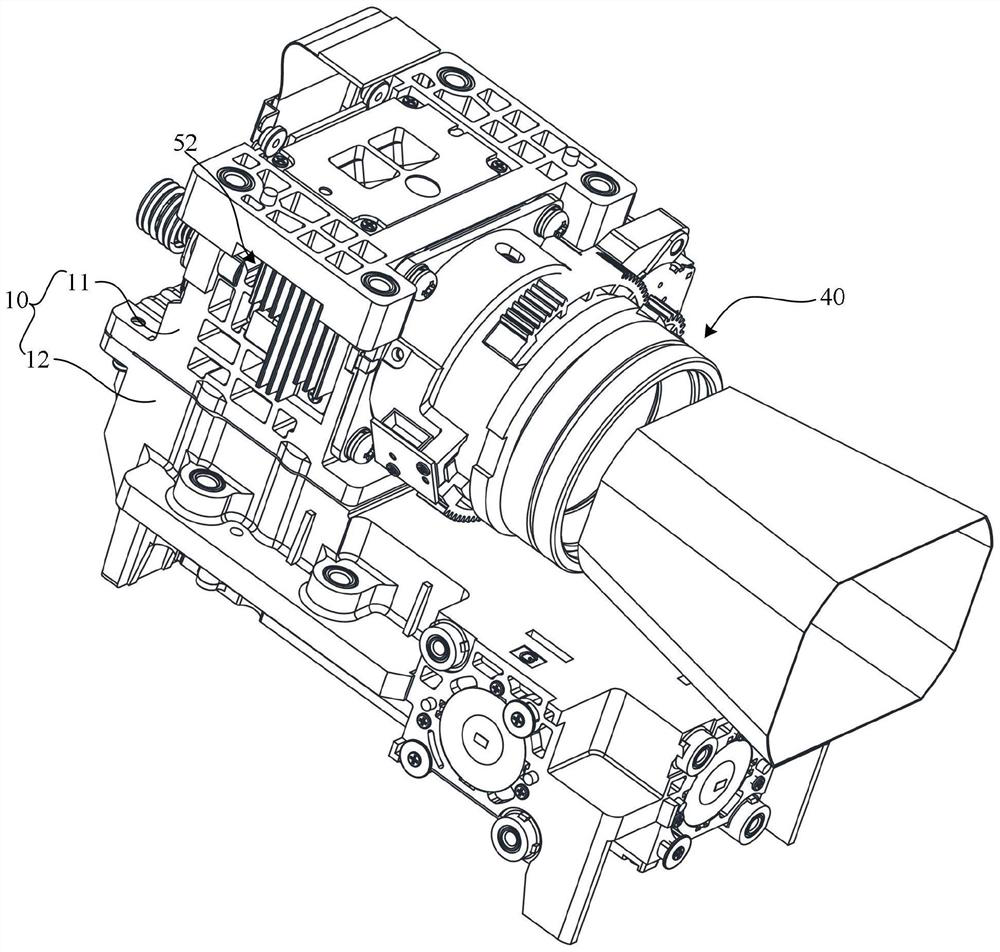

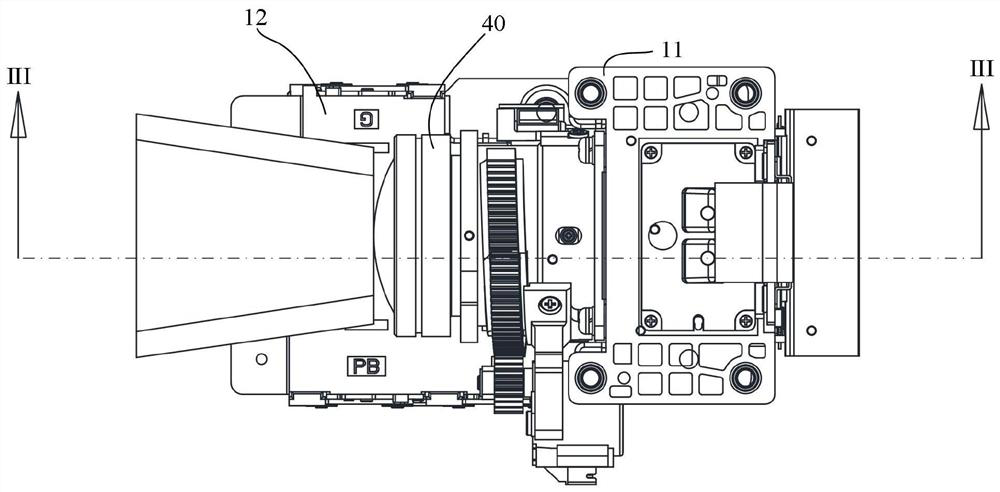

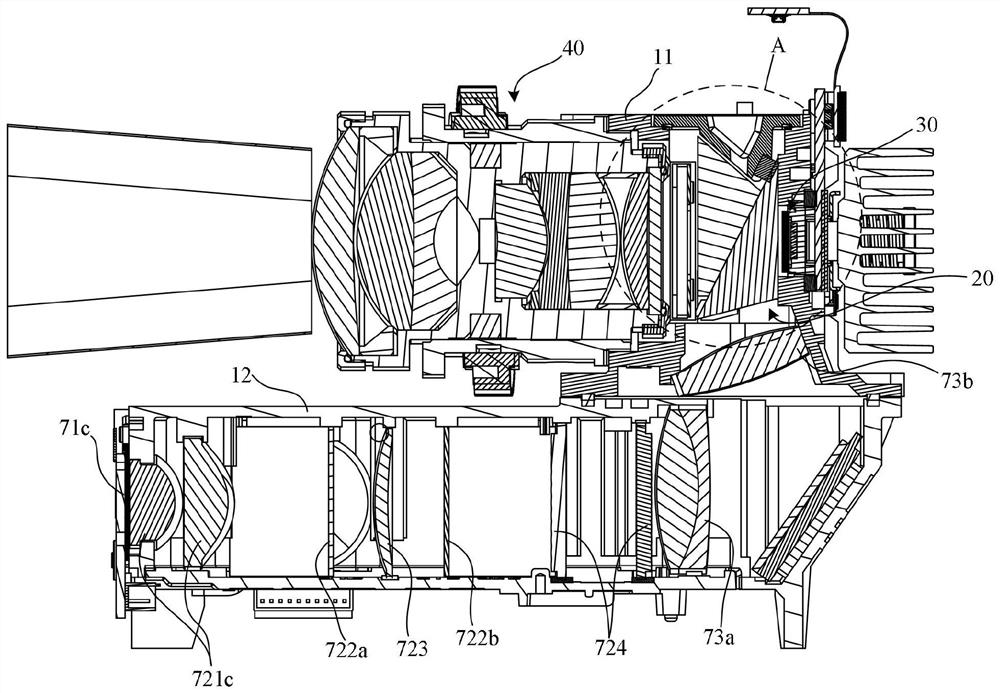

[0049] Please refer to Figure 1 to Figure 4 , Figure 7 ,and Figure 14 , In one embodiment, the optical projection machine of the present invention includes a housing 10, a dichroic prism 20, a DMD light modulator 30, a projection lens 40, and a light-shielding heat dissipation assembly 50. The housing 10 has an inner cavity 111 and communicates with the inner cavity 111. The front mounting port 112 and the rear mounting port 113; the inner wall surface of one side of the inner cavity 111 in the left and right direction is provided with a plug port 114 adjacent to the front mounting port 112; the housing 10 is far away from the plug port 114 in the left and right direction The outer surface of the corresponding socket 114 is provided with a through groove 115;

[0050] The DMD light modulator 30 is installed in the rear installation port 113, and the light modulation area of the DMD light modulator 30 is set forward; the projection lens 40 is installed in the front insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com