Clamp device for in-board strain DIC measurement of plate

A fixture device and plate technology, which can be used in measuring devices, workpiece clamping devices, optical devices, etc., can solve problems such as difficulty in adjusting the normal clamping force, poor accuracy, and poor measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

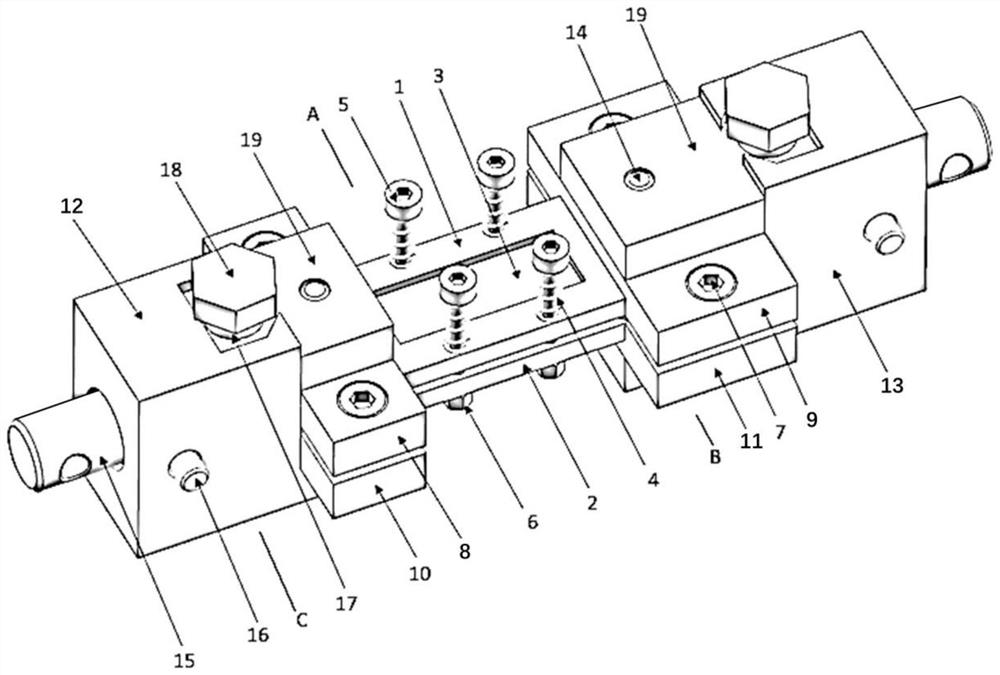

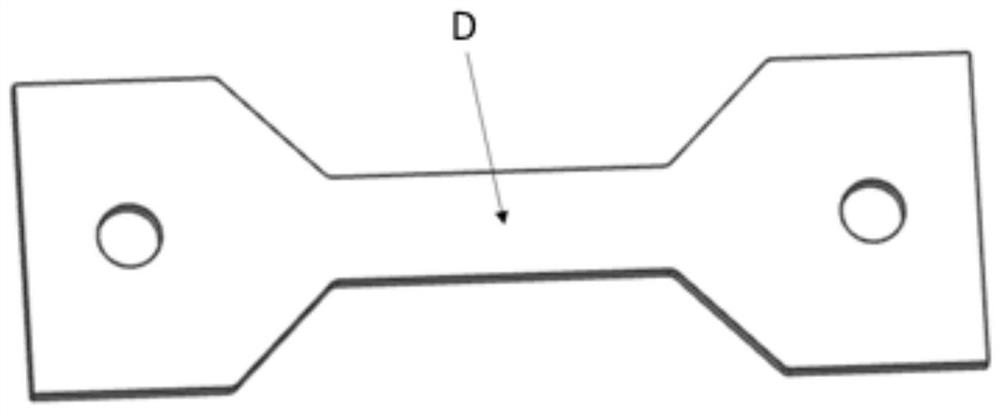

[0022] Such as figure 1 and figure 2 As shown, this embodiment includes: a force-adjusting splint mechanism A with a visible window, a position-adjusting splint mechanism B and a clamping handle mechanism C, wherein: the position-adjusting splint mechanism B is arranged at both ends of the force-adjusting splint mechanism A, The clamping handle mechanism C is set at both ends of the positioning splint mechanism B, and the three are fixed in turn to prevent the sample D from bending in the normal direction.

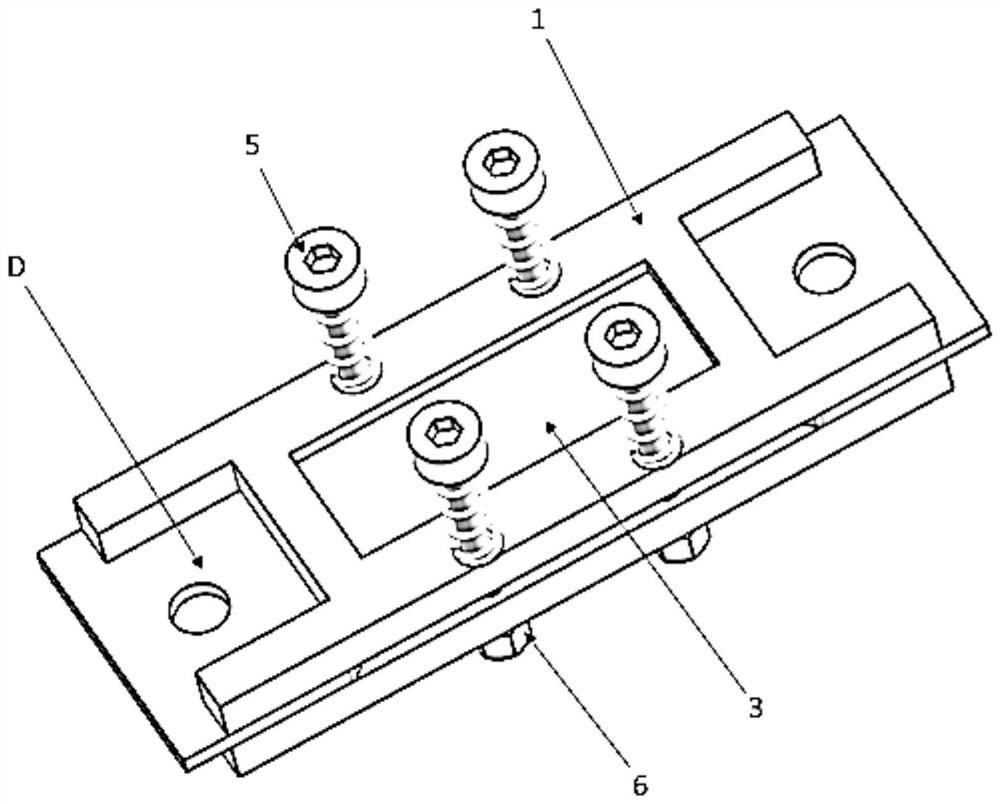

[0023] Such as image 3 and Figure 4 As shown, the force-adjusting splint mechanism A includes: an upper splint 1, a lower splint 2, a transparent splint 3, a first bolt 5 with a spring 4 and a nut 6, wherein: the transparent splint 3 is embedded in the upper splint by screws 7 In the visible window of 1, between the upper splint 1 and the lower splint 2, the pressing force is adjusted by the cooperation of the first bolt 5 with the spring 4 and the nut 6.

[0024] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com