Range hood and control method thereof

The technology of a range hood and a control method is applied in the directions of removing range hood, heating method, household heating, etc., and can solve the problem of easy escape of range hood and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

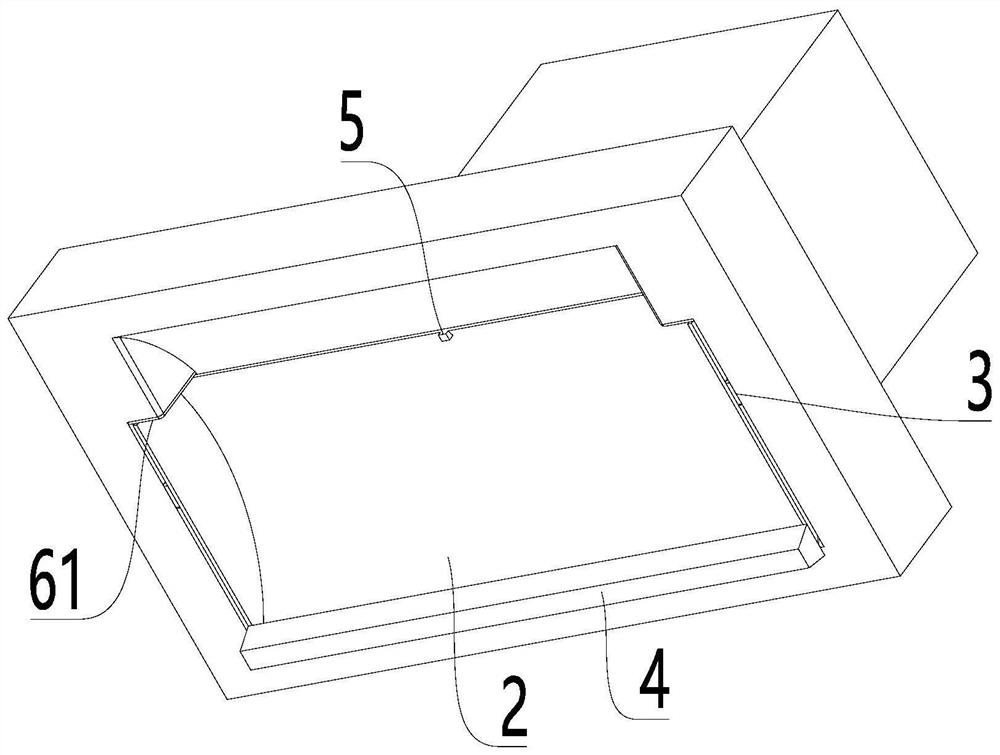

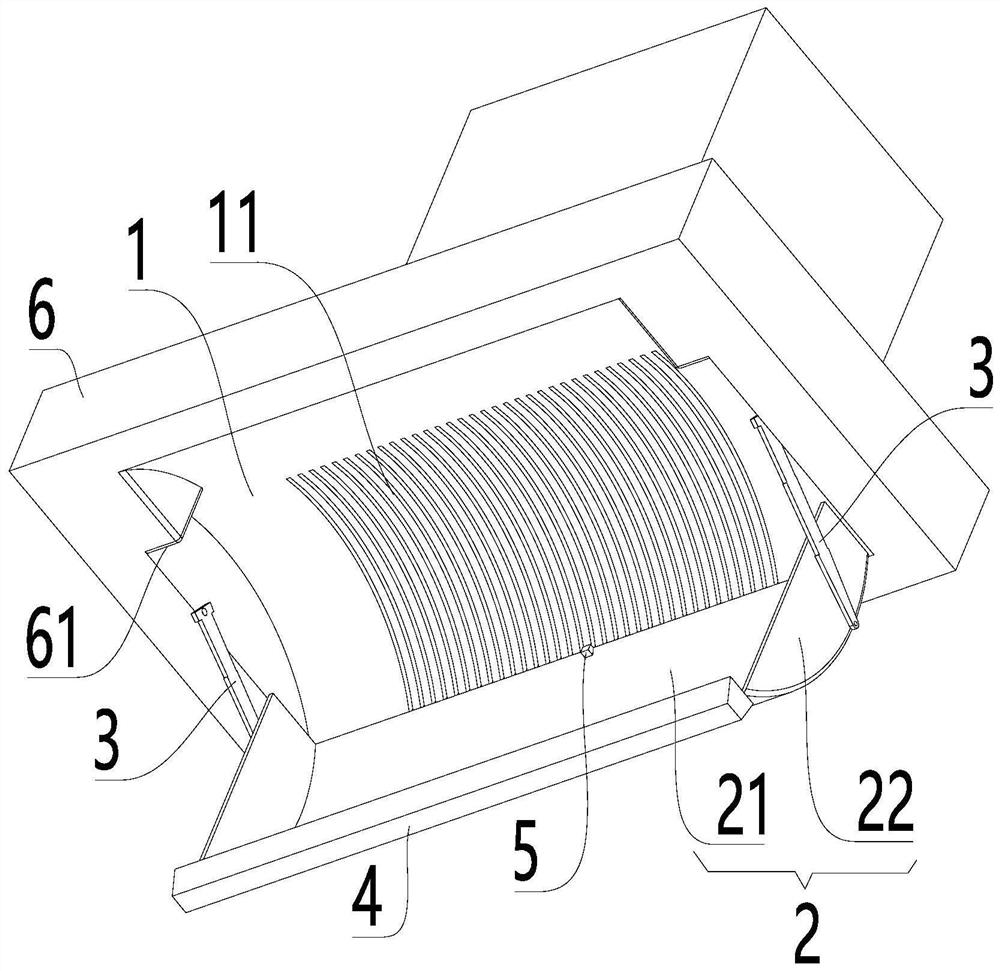

[0050] combine Figure 1-Figure 5 As shown, the range hood provided in this embodiment includes:

[0051] Range hood body 6;

[0052]The oil screen 11 is arranged on the body 6 of the range hood;

[0053] The smoke guide plate 2 is movably connected with the range hood body 6, the smoke guide plate 2 has an initial state of at least partially covering the oil screen 11, and a working state of making way for the oil screen 11; as well as

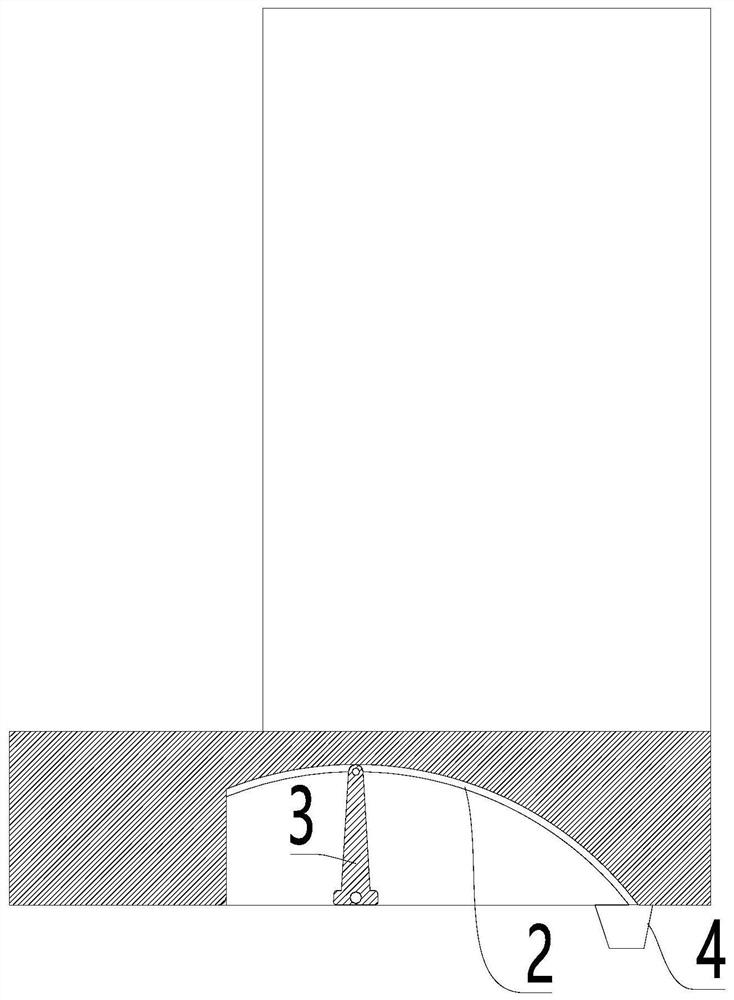

[0054] The guide part 3 is adapted to guide the smoke guide plate 2 to switch between the working state and the initial state relative to the range hood body 6; when the smoke guide plate 2 is switched from the initial state to the working state , the first end of which extends downward along the height direction.

[0055] The range hood provided in this embodiment is provided with a smoke guide plate 2 that is movably connected to the range hood body 6, and when the smoke guide plate 2 is switched from the initial state to the working st...

Embodiment 2

[0090] This embodiment provides a control method for the range hood described in Embodiment 1, including:

[0091] When the range hood is in the standby state, turn on the smoke sensor module;

[0092] Based on the oil smoke concentration obtained by the smoke sensor module, the position state of the smoke deflector is controlled.

[0093] Specifically, the controlling the position state of the smoke guide plate based on the oil smoke concentration obtained by the smoke sensing module includes:

[0094] When the oil fume concentration is greater than C1, adjust the smoke deflector to the working state;

[0095] When the oil fume concentration is less than C2, adjust the smoke deflector to an initial state; wherein, C1>C2.

[0096]When the range hood is in the standby state, the smoke sensor module is turned on. If the smoke sensor module detects oil smoke and reaches a certain concentration C1, it will automatically control the synchronous opening of the smoke guide plate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com