Regeneration cooling channel with truss structure

A truss structure, regenerative cooling technology, applied in combustion methods, combustion chambers, combustion equipment, etc., can solve problems such as poor space utilization, need to improve thermal insulation capabilities, and a large proportion of metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

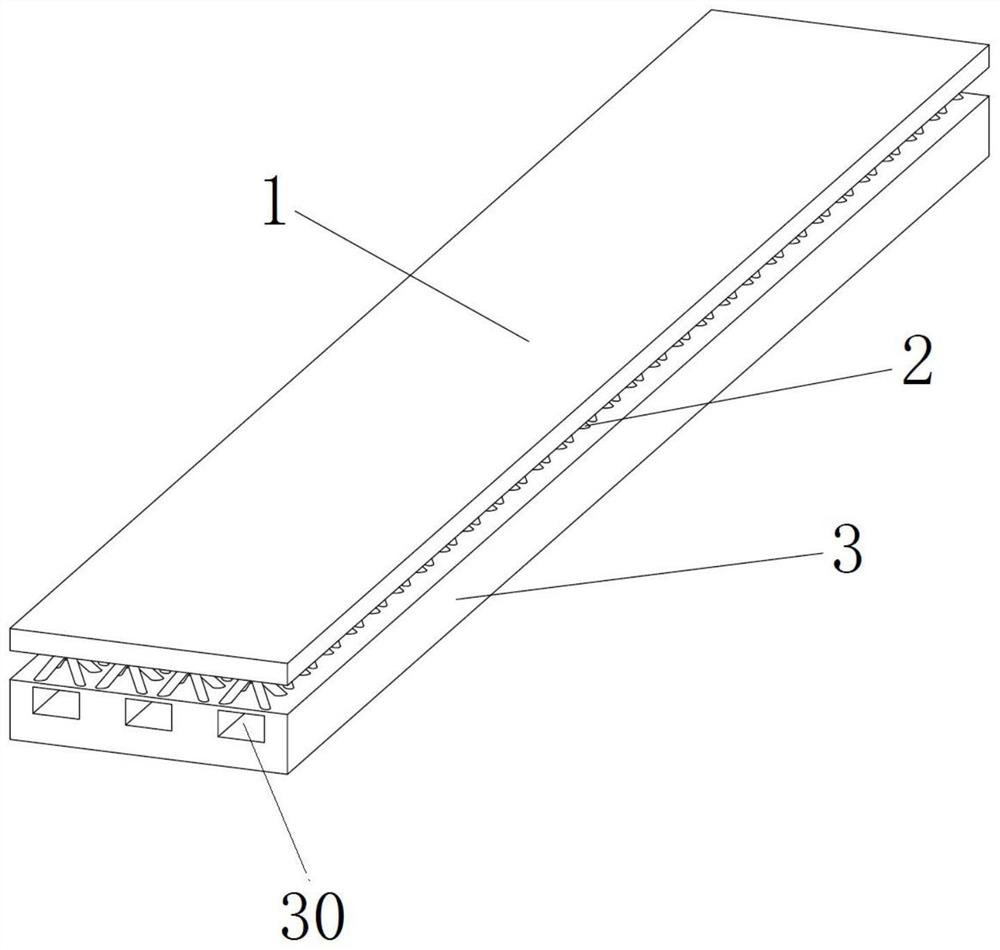

[0029] see figure 1 and figure 2 , a regenerative cooling channel with a truss structure, including an outer wall 1, a truss structure 2 and a cooling channel 3;

[0030] A cavity is provided between the outer wall 1 and the cooling passage 3, and a truss structure 2 is provided in the cavity.

[0031] The truss structure 2 of the present invention is located in the cavity between the outer wall 1 and the cooling passage 3, which not only supports and connects the inner and outer walls, but also forms a cavity to reduce the structural weight. The invention is used for thermal protection of the wall surface of the combustion chamber of the hydrocarbon fuel ramjet engine, and can meet the requirements of reducing the structural weight and enhancing the heat insulation capacity of the wall surface of the current hypersonic aircraft combustion chamber.

[0032] see image 3 , the truss structure 2 includes a hollow frame structure constructed by a plurality of support rods 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com