Electricity-burning-mechanical energy comprehensive rock breaking drill

A mechanical energy and rock-breaking technology, which is applied to drill bits, thermal energy drilling, drilling equipment, etc., can solve the problems of low temperature of the wall builder, unsatisfactory wall building effect, unstable temperature control, etc., and achieve good heat conduction effect and high temperature Uniform and controllable, good wall-building effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings.

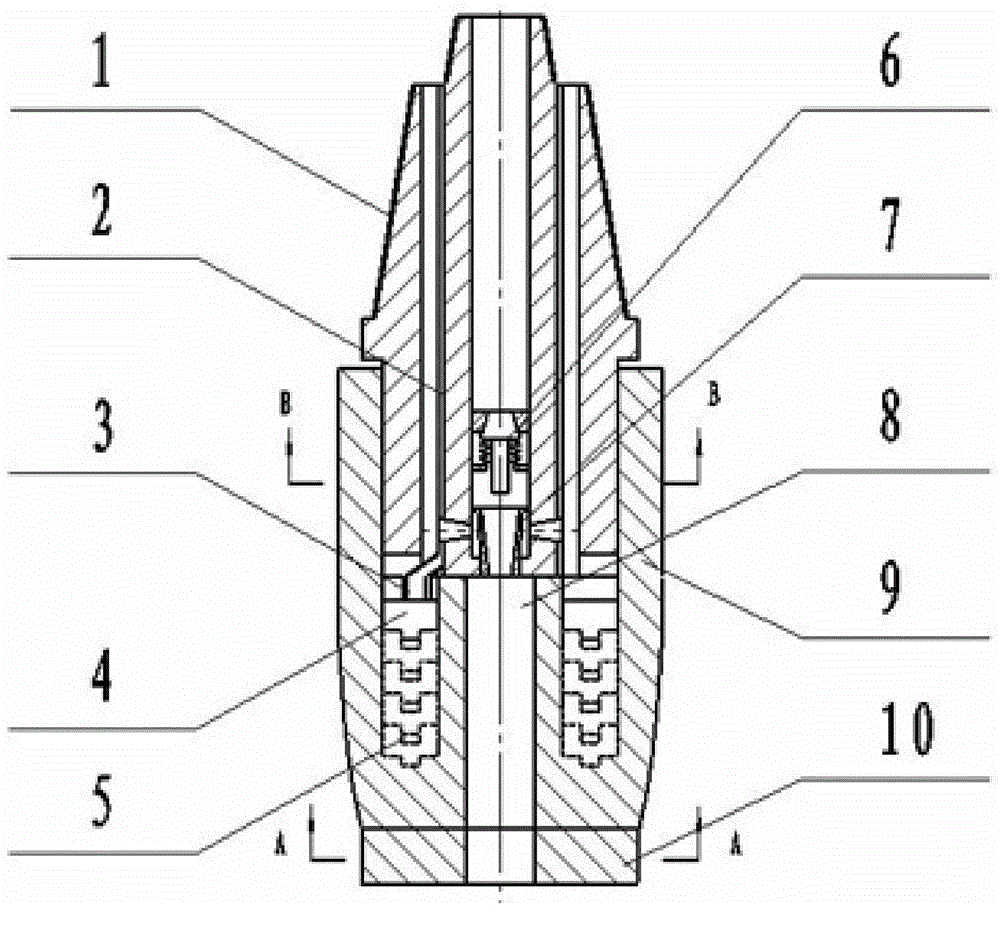

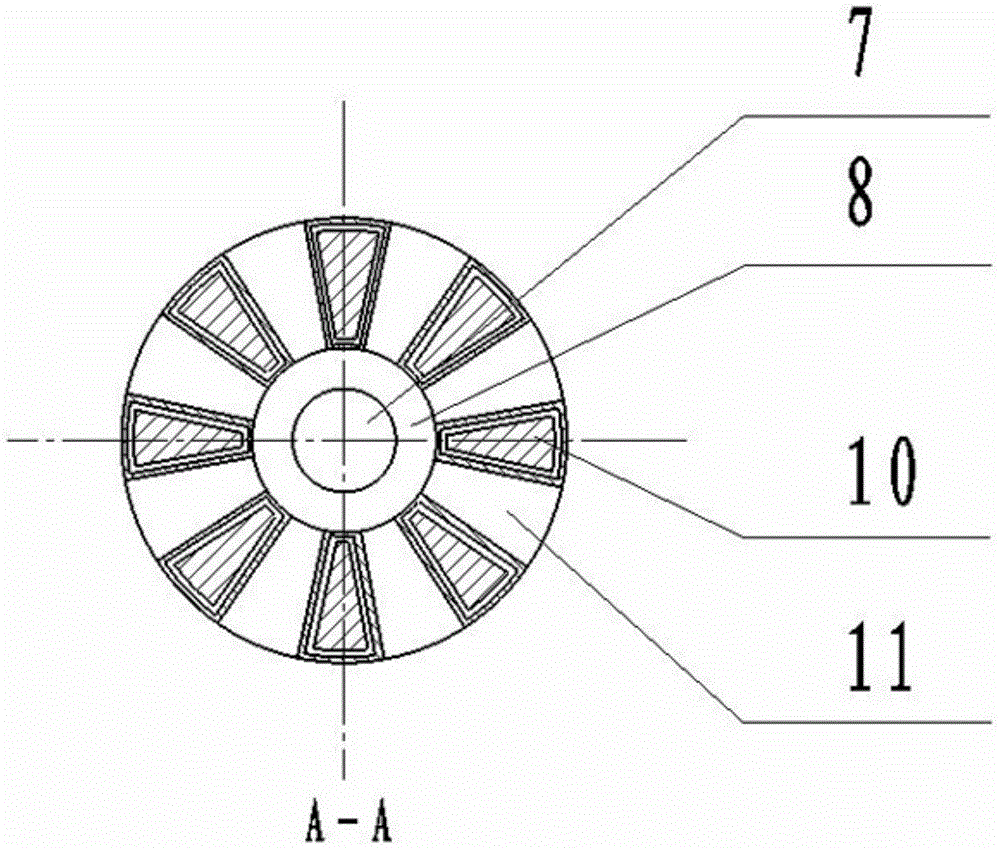

[0023] like Figure 1 to Figure 3 As shown, an electric-combustion-mechanical energy comprehensive rock-breaking drill bit includes a threaded joint 1, a wall builder 9, a controller 6, an injector 7, an electric heater 4, a cable 2, an insulator 3 and a heat conducting element.

[0024] like Figure 1 to Figure 3 As shown, the lower end of the threaded joint 1 is connected to the wall builder 9 through threads (the wall builder 9 is set on the threaded joint 1), and the threaded joint 1 is provided with an annular hole and a central hole (both are through holes). The wall builder 9 is provided with an annular groove and a combustion chamber (the combustion chamber is a central through hole). The central hole communicates with the combustion chamber. The outlet of the combustion chamber is located on the bottom surface of the wall builder 9. The controller 6 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com