High-breakage-resistance multi-layer kraft board paper and preparation method thereof

A kraft box and cardboard technology, applied in the field of papermaking, can solve the problems of reducing the amount of wood pulp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

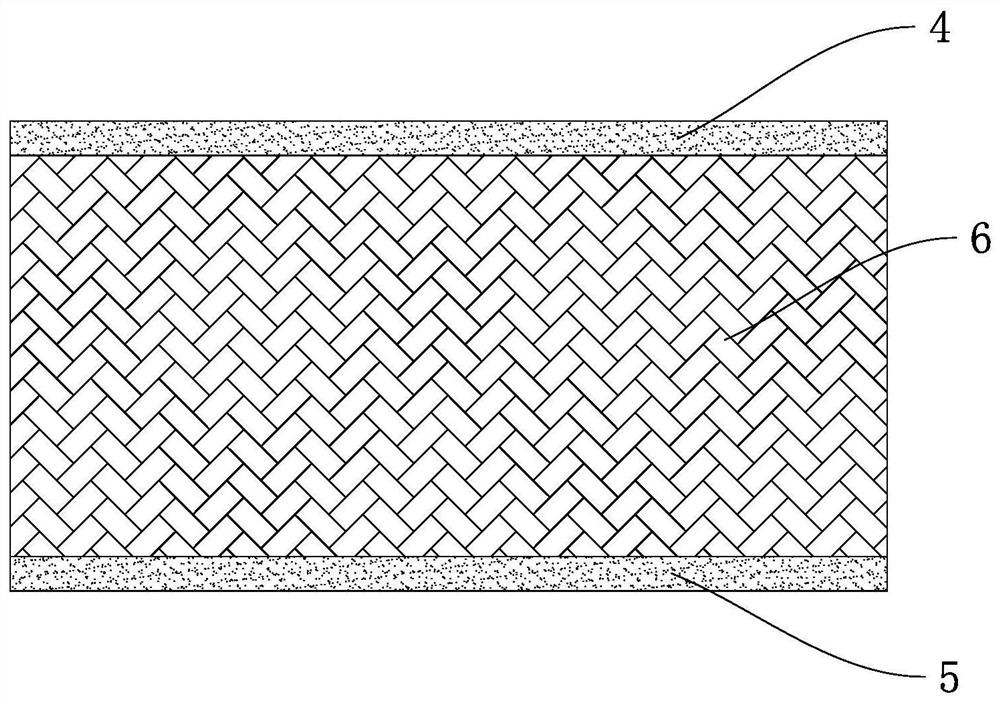

[0035] This embodiment provides a kind of preparation method of high breakage resistant multi-layer kraft liner paper, such as figure 1 shown, including the following steps:

[0036] Step 1: Using waste paper, waste paper pulpboard, and wood pulp board as raw materials, the waste paper and waste paper pulpboard are pulped by a hydraulic pulper, and after removing slag and rough sieving, enter the fiber classifying sieve, and sieve to obtain Long-fiber pulp with a fiber length of 2.0 or more, medium-fiber pulp with a fiber length of 1.1-2.0 mm, and short-fiber pulp with a fiber length of 1.1 mm or less. Wood pulp is formed after the impurity removal and double disc mill beating treatment;

[0037] Step 2: Mix long-fiber pulp and short-fiber pulp at a ratio of 80:20 in parts by mass to obtain waste paper pulp for the surface layer, and then mix the waste paper pulp and wood pulp for the surface layer at a ratio of 0:100 in parts by mass. Mix evenly to obtain pulp for the surfa...

Embodiment 2

[0043] This embodiment provides a kind of preparation method of high breakage resistant multi-layer kraft liner paper, such as figure 1 shown, including the following steps:

[0044] Step 1: Using waste paper, waste paper pulpboard, and wood pulp board as raw materials, the waste paper and waste paper pulpboard are pulped by a hydraulic pulper, and after removing slag and rough sieving, enter the fiber classifying sieve, and sieve to obtain Long-fiber pulp with a fiber length of 2.0 or more, medium-fiber pulp with a fiber length of 1.1-2.0 mm, and short-fiber pulp with a fiber length of 1.1 mm or less. Wood pulp is formed after the impurity removal and double disc mill beating treatment;

[0045] Step 2: Mix long-fiber pulp and short-fiber pulp at a ratio of 90:10 by mass to obtain surface layer waste paper pulp, and then mix the surface layer of waste paper pulp with wood pulp at a ratio of 90:10 by mass, Mix evenly to obtain pulp for the surface layer of wood pulp. After m...

Embodiment 3

[0051] This embodiment provides a kind of preparation method of high breakage resistant multi-layer kraft liner paper, such as figure 1 shown, including the following steps:

[0052] Step 1: Using waste paper, waste paper pulpboard, and wood pulp board as raw materials, the waste paper and waste paper pulpboard are pulped by a hydraulic pulper, and after removing slag and rough sieving, enter the fiber classifying sieve, and sieve to obtain Long-fiber pulp with a fiber length of 2.0 or more, medium-fiber pulp with a fiber length of 1.1-2.0 mm, and short-fiber pulp with a fiber length of 1.1 mm or less. Wood pulp is formed after the impurity removal and double disc mill beating treatment;

[0053] Step 2: Mix long-fiber pulp and short-fiber pulp at a ratio of 85:15 in parts by mass to obtain waste paper pulp for the surface layer, and then mix the waste paper pulp and wood pulp for the surface layer at a ratio of 50:50 in parts by mass. Mix evenly to obtain pulp for the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

| Dimension length | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com