Hot metal global impact mixing long life agitator

A stirrer, long-life technology, applied in the direction of stirring devices, furnaces, lighting and heating equipment, etc., can solve the problems that are not conducive to the quality assurance of the stirrer and the mixing characteristics of the stirrer, increase the difficulty of controlling the accuracy of the structural parameters of the stirrer, and increase the manufacturing process. Material loss and other issues, to achieve the effect of improving structural integrity and deep desulfurization stability of molten iron, reducing forced eddy current zone, reducing direct contact area and wear speed

Active Publication Date: 2022-06-03

武汉钢铁有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

And in actual production, the application effect of significantly improving the technical and economic indicators of molten iron KR stirring desulfurization has been achieved. Desulfurization agitator, authorized announcement number CN107904348B "disclosed the longevity technology of the agitator, which effectively curbs the crack damage of the agitator, but the strong upper and lower circulation flow field scours the agitation blade, which leads to the rapid wear of the agitation blade, which restricts the The stable maintenance of the high-efficiency mixing and dispersing effect of the desulfurizer and the service life of the agitator. At the same time, the double-layer positive and negative spiral blades are arranged at intervals. It increases the preparation cost of the agitator, prolongs the preparation time, and increases the material loss in the manufacturing process. On the other hand, it increases the difficulty of controlling the accuracy of the structural parameters of the agitator, which is not conducive to the quality assurance of the agitator and the maintenance of mixing characteristics.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

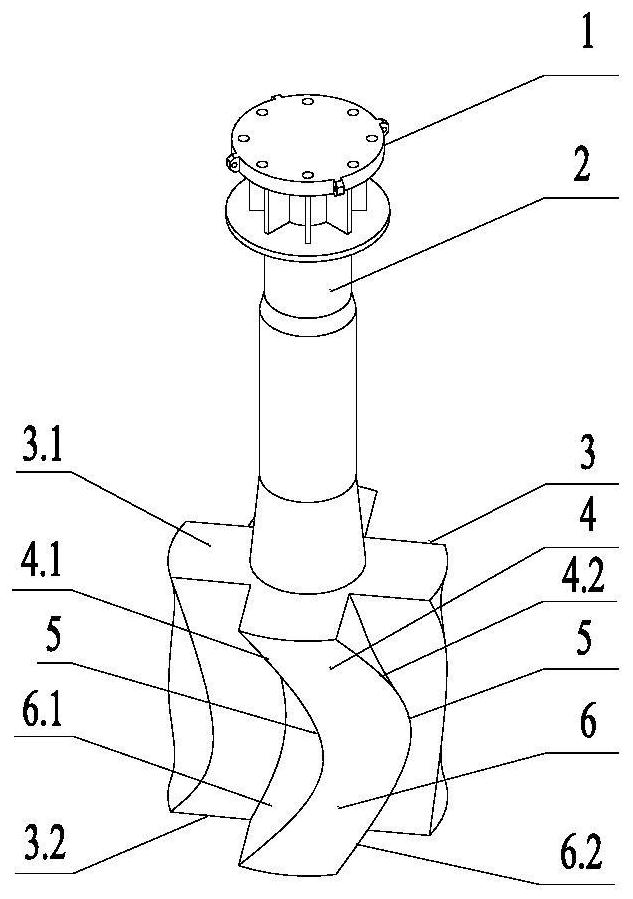

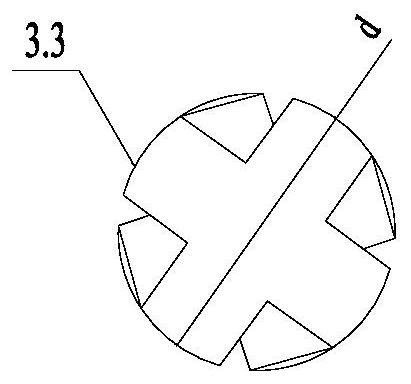

[0041] As shown in Figure 1 to Figure 7 and Figure 11, molten iron global impact mixing long-life agitator, comprising agitator connection flange 1,

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

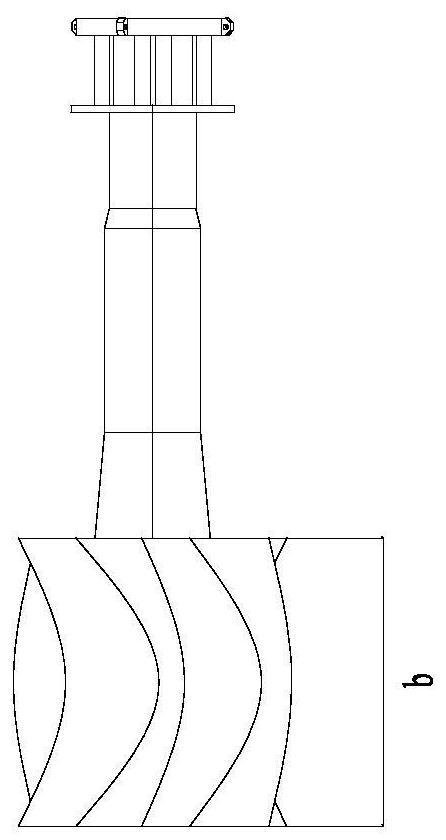

The invention discloses a long-life stirrer for full-area impact mixing of molten iron, comprising a stirrer connecting flange, a stirring shaft and a stirring blade; the stirring blade is a single-layer special-shaped structure stirring blade, and the top surface and the bottom surface of each stirring blade are planes and outer surfaces It is a circular arc surface, the upper anti-iron surface and the upper back iron surface are positive helical surfaces, the lower anti-iron surface and the lower back iron surface are reverse helical surfaces; the forward helical surface of the upper anti-iron surface and the lower anti-iron surface The junction of the reverse helical surface is an arc-shaped transition surface, and the junction of the forward helicoid of the upper back iron surface and the reverse helicoid of the lower back iron surface is an arc-shaped transition surface. Through the structural design of special-shaped stirring blades and the optimization of structural parameters, the erosion wear area and erosion process of the molten iron in the agitator are significantly reduced, the service life of the agitator is greatly extended, the size of the upper and lower circulation flow areas of the agitation is enlarged, and the velocity of the upper and lower circulation flow is increased. And kinetic energy, to ensure the reliability and stability of the radial discharge jet impingement flow field of the stirring up and down circulation flow.

Description

Hot metal global impact mixing long-life agitator technical field The present invention relates to the technical field of molten iron pretreatment, be specifically related to a kind of molten iron global impact mixing long-life stirring device. Background technique Hot metal KR mechanical stirring desulfurization process crosses a single layer of rectangular or inverted right-angled trapezoidal blades immersed in molten iron. The rotary stirring of the agitator is arranged by the fork, so that the desulfurizing agent added on the molten iron surface is circulated into the molten iron, so that the desulfurizing agent can be mixed in the molten iron. continuous dispersion and interfacial desulfurization reaction in preferred process. According to hot metal KR mechanical stirring desulfurization fluid dynamics research data report, from KR stirring and mixing macroscopic behavior. Look, in the process of high-speed rotation of the agitator, due to the centrifugal fo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21C7/064C21C1/02F27D27/00

CPCC21C7/064C21C1/02F27D27/00Y02P10/20

Inventor 欧阳德刚宋泽啟刘路长吴杰李华孙伟杨新泉邓品团朱万军沈继胜

Owner 武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com