Method and system for dealdehyding and upgrading epoxypropane

A kind of propylene oxide, upgrading technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

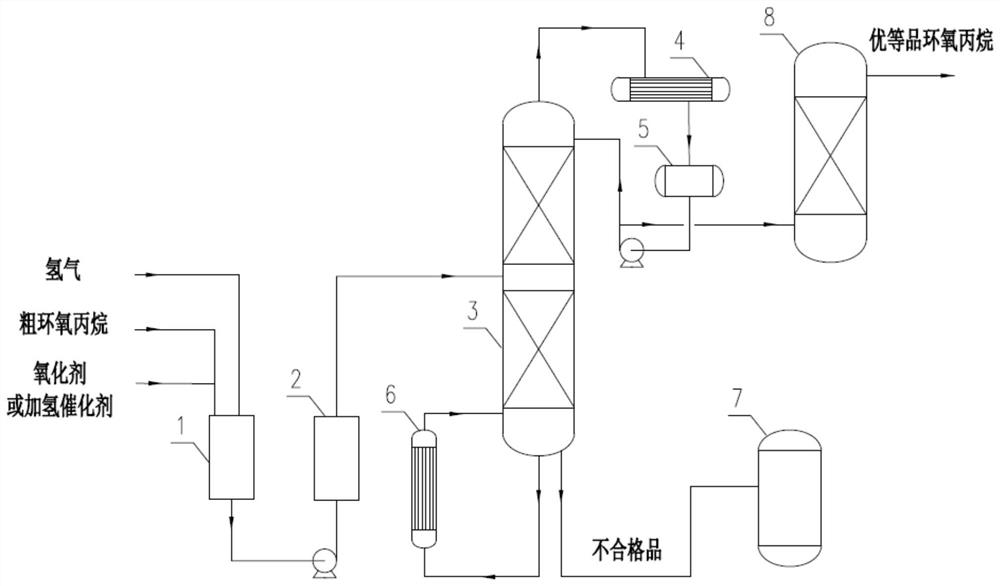

[0038] Such as figure 1 Shown, a kind of system of propylene oxide dealdehyde upgrading, comprises reactor 1, membrane separator 2, rectifying tower 3, defective product tank 7 and dehydration tower 8; The outlet of described reactor 1 It is connected with the inlet of membrane separator 2, and the permeation side outlet of said membrane separator 2 is connected with the inlet of rectification tower 3, and the bottom of rectification tower 3 is equipped with reboiler 6, and the outlet of rectification tower 3 tower kettle is The feed port is connected with the unqualified product tank 7, the rectifying tower 4 top discharge port or the side line discharge port is connected with the condenser 4, the discharge port of the condenser 4 is connected with the reflux tank 5, and the discharge port of the reflux tank 5 They are respectively connected to the reflux port of the rectification tower 3 and the feed port of the dehydration tower 8.

[0039]The reactor 1 is a reactor. The ...

Embodiment 2

[0047] On the basis of the system for removing and upgrading propylene oxide described in Example 1, the outlet of the reactor 1 is directly connected to the inlet of the rectifying tower 3 .

[0048] The method for the dealdehydeization and upgrading of propylene oxide based on the system of the present embodiment comprises the following steps:

[0049] Step (1), put 1000g of a certain propylene oxide crude product (wherein the acetaldehyde content is 0.128%wt, the propionaldehyde content is 0.481%wt, the water content is 0.18%wt), 40g of sodium hypochlorite solution (10%wt) into the reaction kettle, open Stir to make the materials mix evenly, pour nitrogen into the kettle until the pressure in the kettle is 0.2MPa, heat to 70°C and keep for 0.5 hours to end the reaction;

[0050] Step (2), the material obtained in step (1) is sent to a rectification tower (the number of theoretical plates is 15, and the feed position is at the 6th plate), the operating pressure of the rectif...

Embodiment 3

[0053] On the basis of the system of propylene oxide dealdehydedization and upgrading described in embodiment 1, adjust reactor 1 to be a fixed bed, fill 30g loading capacity in the fixed bed and be 8%Ni / activated carbon catalyst; The discharge of reactor 1 The port is directly connected with the inlet of the rectification tower 3; the dehydration tower 8 is filled with activated alumina.

[0054] The method for the dealdehydeization and upgrading of propylene oxide based on the system of the present embodiment comprises the following steps:

[0055] Step (1), feed hydrogen into the fixed bed, adjust the back pressure valve to control the pressure of the fixed bed to 1.5MPa, heat to 90°C, inject crude propylene oxide (wherein the content of acetaldehyde is 0.083%wt, the content of propionaldehyde is 0.514 %wt, water content 0.38%wt), control space velocity is 4h -1 , the hydrogen-thane ratio is 500:1;

[0056] Step (2), the material obtained in step (1) is sent to a rectific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com