Dust suppression feeding structure for powder type raw materials in textile industry

A textile industry and material feeding technology, which is applied in the direction of conveyor control device, conveyor objects, loading/unloading, etc., can solve the problems of raw material scattering, powdery raw material damage, and increased use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

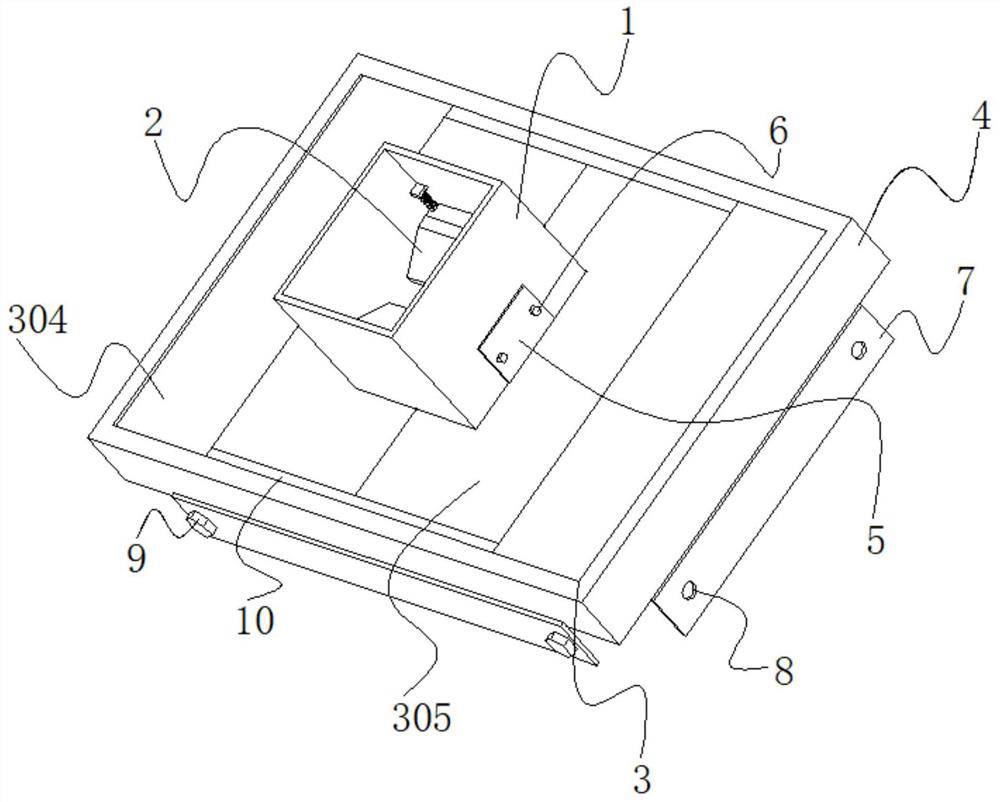

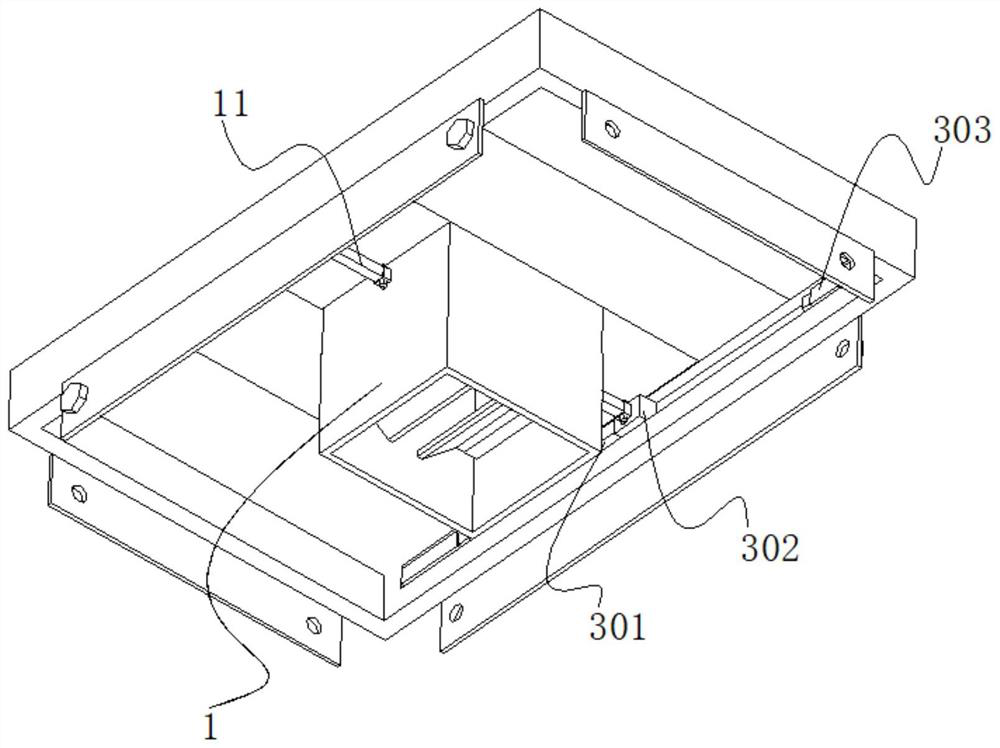

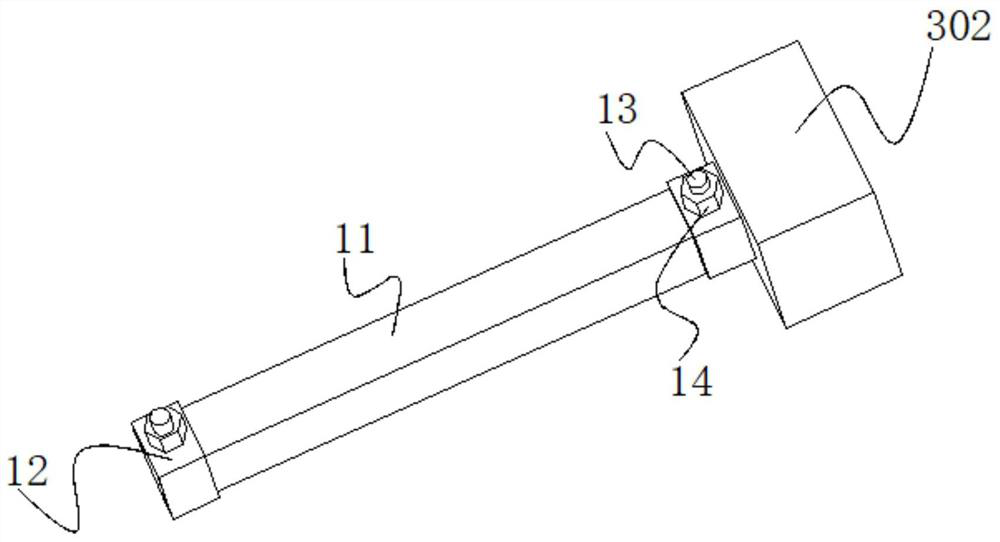

[0034] see Figure 1-6As shown, the present invention is a dust-suppressing feed structure for powder-type raw materials in the textile industry, including a mounting frame 4, a feed body 1, a dust-suppressing part 2 and an adjusting part 3, and the adjusting part 3 includes a chute 301, a sliding Block 302, hydraulic cylinder 303, movable pipe 304 and L-shaped movable plate 305, the middle sliding block 302 in the middle part chute 301 of the mounting frame 4 is flexibly connected with the hydraulic cylinder 303 in the middle part of one side, and the inner side of the sliding block 302 The feed body 1 is connected between them, and the L-shaped movable plate 305 connected to the middle part of both sides of the feed body 1 is slidably connected to the middle part of the mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com