Automatic saw dust collecting tank for disk saw

A technology of automatic collection and collection tank, which is applied in the direction of manufacturing tools, wood processing equipment, bark area/debris/dust/waste removal, etc. It can solve the problems of insufficient control of sawdust and affecting the environment of the construction site, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The automatic collection tank for sawdust of a circular saw according to the present invention includes a collection tank body.

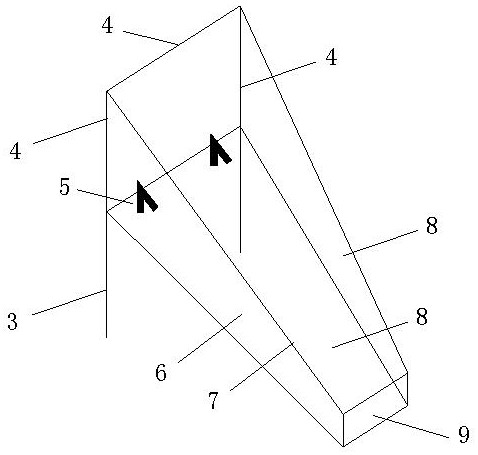

[0027] see now figure 2 , figure 2 It is a structural schematic diagram of an automatic sawdust collection tank for a circular saw according to an embodiment of the present invention. As shown in the figure, the body of the collection tank is a bucket-shaped groove arranged obliquely. The upper mouth of the bucket-shaped groove is large for matching the sawdust outlet frame of the circular saw, and the lower mouth of the bucket-shaped groove is small for sawdust discharge; The upper mouth of the bucket groove is a mouth-shaped frame 4, and the mouth-shaped frame is provided with two vertical rods 3 to support to stand upright on the ground; between the upper mouth of the bucket groove and the lower mouth of the bucket groove, a trapezoidal plank 6 is arranged, and the trapezoidal The iron hinge 5 is used to connect the top of the plank an...

Embodiment 2

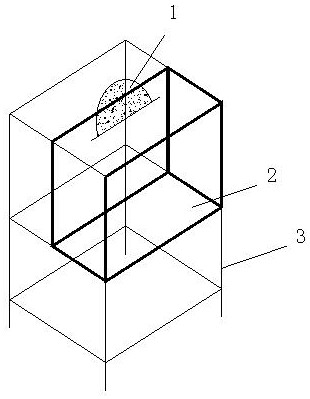

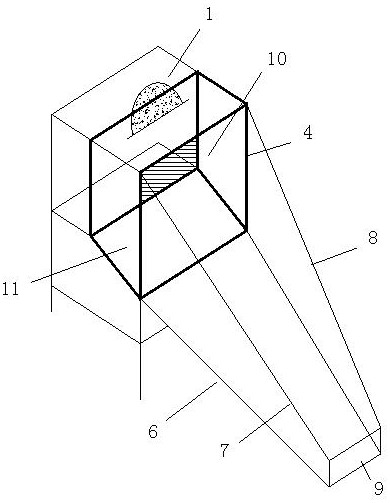

[0029] figure 1 It is a schematic diagram of the structure of the circular saw in the embodiment of the present invention. The circular saw is a frame structure, and it uses four legs 3 to stand on the ground. The circular saw cutting blade 1 is arranged in the center of the upper surface. Saw collection bin 2. Figure 4 It is a schematic diagram showing the transformation of the horizontal bottom plate of the circular saw collecting bin according to the embodiment of the present invention into an inclined bottom plate with the outer opening sloping downward. As shown in the figure, the application of the circular saw dust automatic collection tank in the circular saw is characterized by comprising the following steps:

[0030] a. Transform the horizontal bottom plate of the sawdust collection bin of the circular saw into an inclined bottom plate with the outer opening sloping downwards to match the upper opening of the bucket groove of the sawdust automatic collection tank o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com