Electronically-driven coupled bioelectrochemistry degradation system and method and application of electronically-driven coupled bioelectrochemistry degradation system and method

A bioelectrochemical and driven technology, applied in the field of environmental engineering, can solve the problems that the degradation system cannot degrade and process different types of substances at the same time, and the degradation is difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

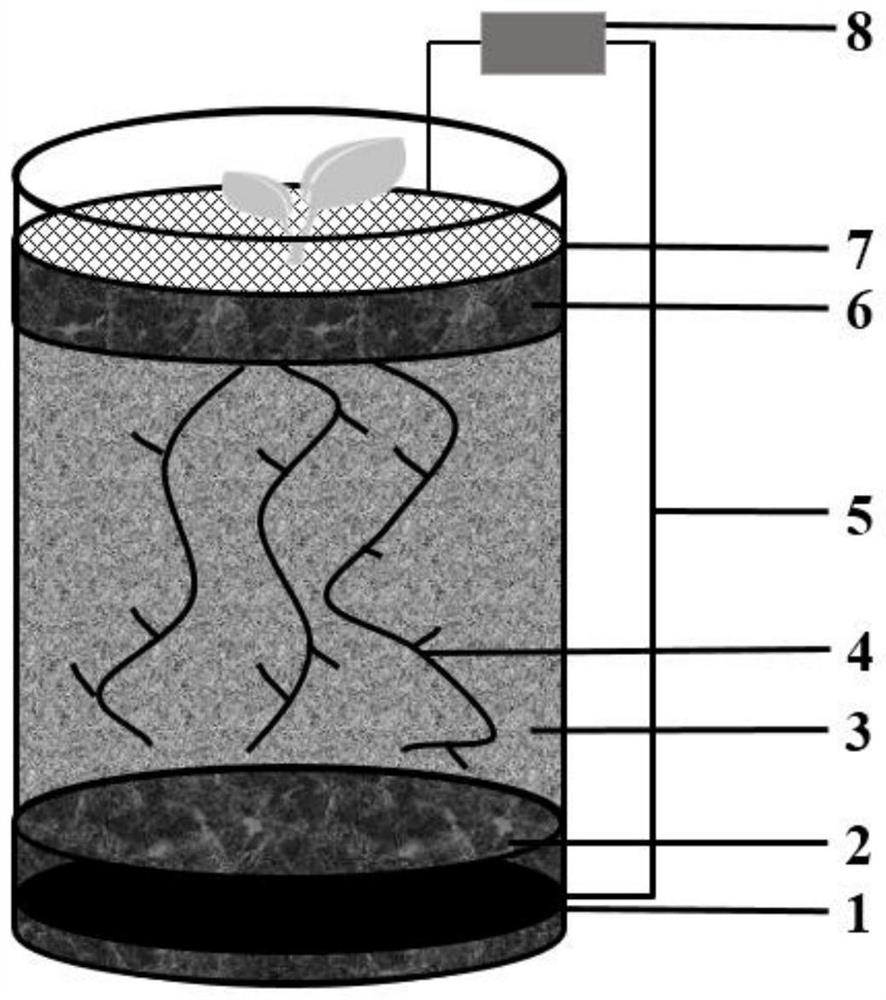

[0030] A degradation method for an electronically driven coupled bioelectrochemical degradation system, comprising the following steps:

[0031] (1) Disperse the semiconductor mineral particles, activate the humic acid, and inoculate the soil to be treated and the anode with anaerobic sludge;

[0032] (2) Mix and stir the semiconductor mineral particles after the dispersion treatment, the humic acid after the activation treatment and the soil inoculated with anaerobic sludge to obtain a soil matrix and form a composite electron transfer network;

[0033] (3) Construct a degradation system. The degradation system consists of anode layer, soil matrix and cathode layer from bottom to top. Plants are planted in the soil matrix to form a plant root-anode composite area, and the degradation system is operated to achieve the degradation of pollutants.

[0034] Among them, the dispersion treatment of semiconductor mineral particles is as follows: crush and sieve the natural minerals (...

Embodiment 2

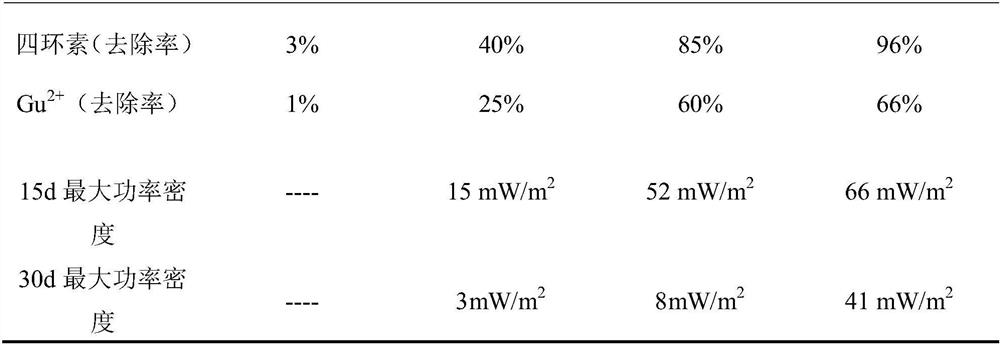

[0040] This example is basically the same as Example 1, except that the pollutant antibiotic in the soil, specifically tetracycline, has an initial concentration of 40 mg / kg.

Embodiment 3

[0042] This embodiment is basically the same as Embodiment 1, except that the pollutants in the soil are heavy metals, specifically Cu 2+ , the initial concentration is 10mg / kg.

[0043] The degradation system of the above-mentioned Examples 1-3 is degraded, and the specific process is: the degradation starts to add 10mL (10g / L) nutrient solution dissolved with sodium acetate, in addition, the nutrient solution is added every seven days to maintain the stability of the device, and the device Placed in a 30-degree incubator for cultivation.

[0044] The degradation results are summarized in Table 1 below. After 45 days of treatment, the concentration of naphthalene in the soil matrix decreased by 5%, 37%, 82% and 93%, respectively. After 45 days, the addition of nutrient solution was stopped and the operation continued for 15 days. In the case of an external resistance of 10Ω, the maximum power density of the three closed-circuit test groups was 15mW / m 2 、52mW / m 2 、66mW / m 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com