Drying oven capable of discharging air uniformly

A technology with uniform air outlet and oven, which is applied to the device for coating liquid on the surface, pretreatment surface, coating and other directions, which can solve the problems of insufficient uniform air and affecting the drying effect of lithium battery pole pieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

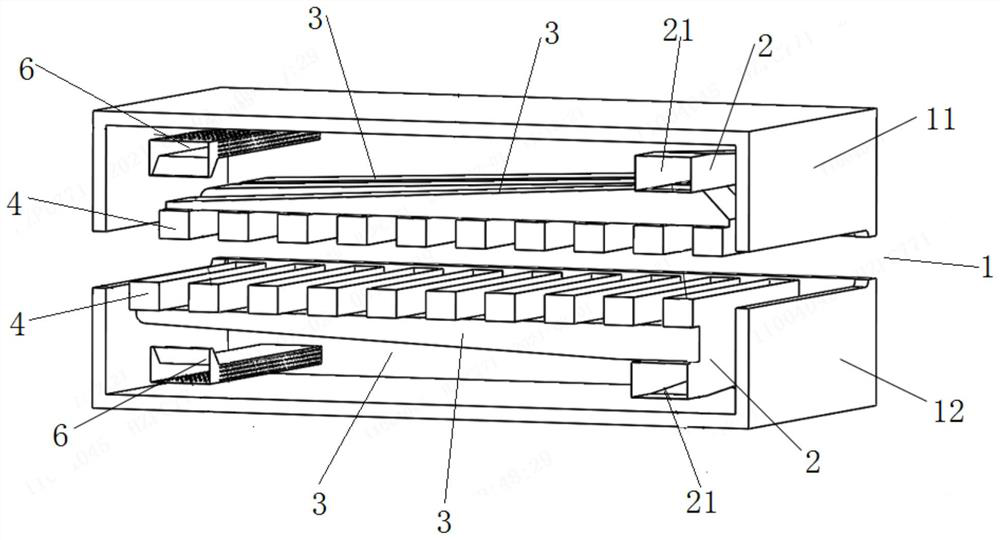

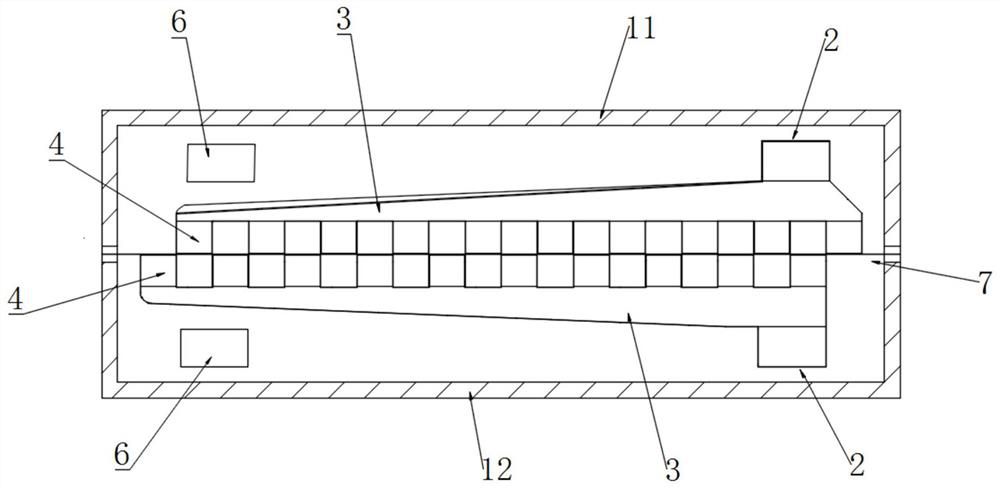

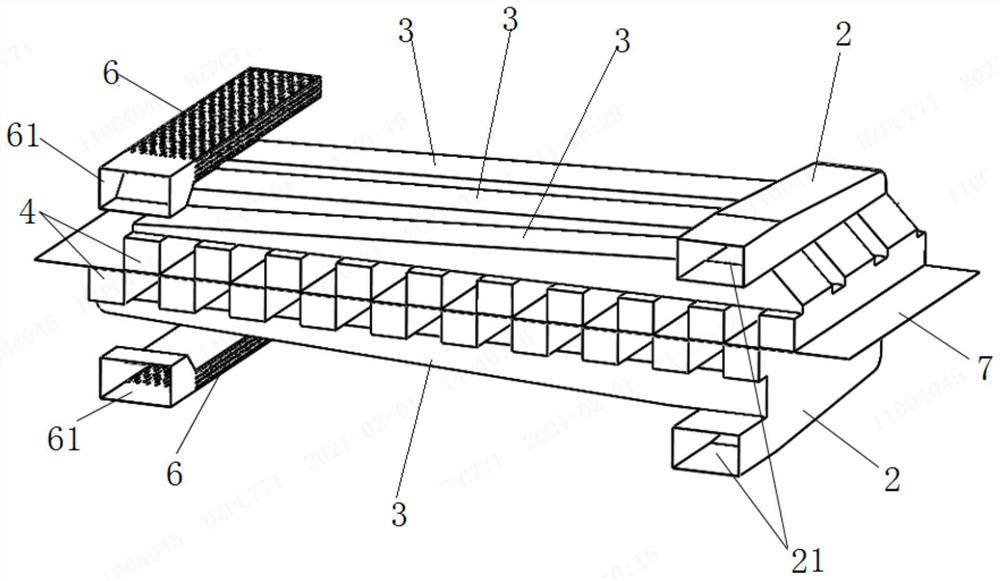

[0026] refer to Figure 1-8 , an oven with uniform air outlet. By improving the structure of the air inlet channel and the blower nozzle, the wind blown by the blower nozzle is more uniform, thereby optimizing the drying effect of pole pieces and other products. The oven includes a box body 1, a first air inlet cavity 2, a second air inlet cavity 3, a blowing nozzle 4 and an air outlet cavity 6. The box body 1 is a structure for installing various parts of the oven. The first air inlet cavity 2 , the second air inlet chamber 3, the blowing nozzle 4 and the air outlet chamber 6 are all arranged in the box body 1, and the first air inlet chamber 2, the second air inlet chamber 3 and the blowing nozzle 4 are connected in sequence, The first air inlet 21 of the first air inlet cavity 2 and the air outlet 61 of the air outlet cavity 6 are arranged outside the box body 1, so that the drying wind can enter from the first air inlet 21 of the first air inlet cavity 2, Enter the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com