A drying device and drying process thereof

A drying device and process technology, applied in drying, drying machine, drying gas layout and other directions, can solve the problems of increasing heat waste, increasing the amount of hot water in the drying cylinder, etc., to improve water temperature, speed up evaporation, improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Attached to the following Figure 1-7 This application will be described in further detail.

[0050] The embodiment of the present application discloses a drying device.

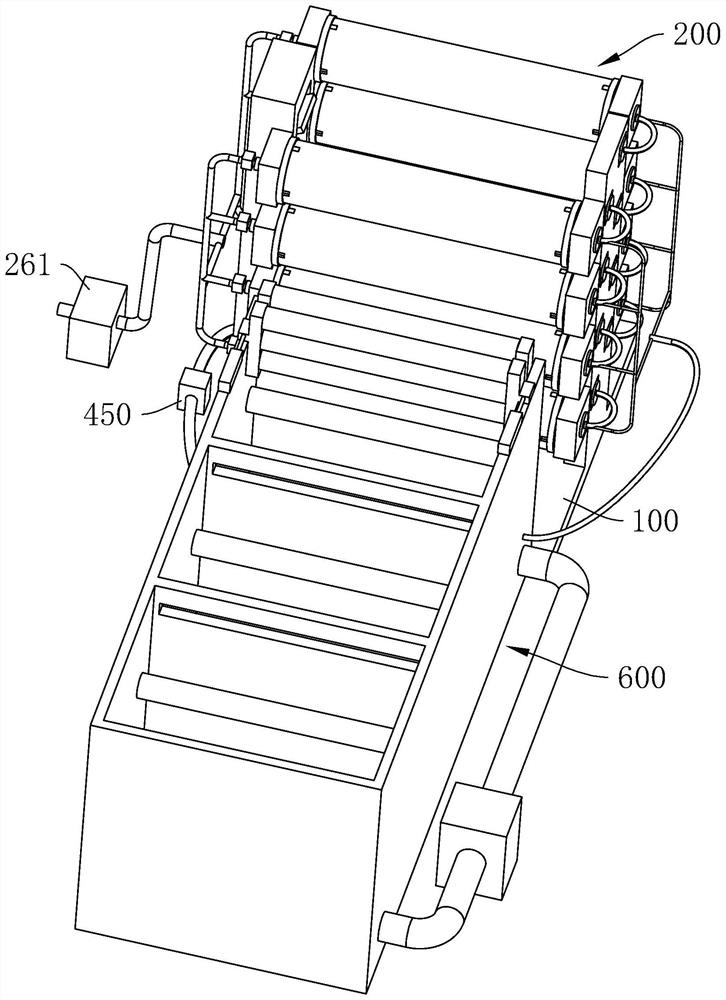

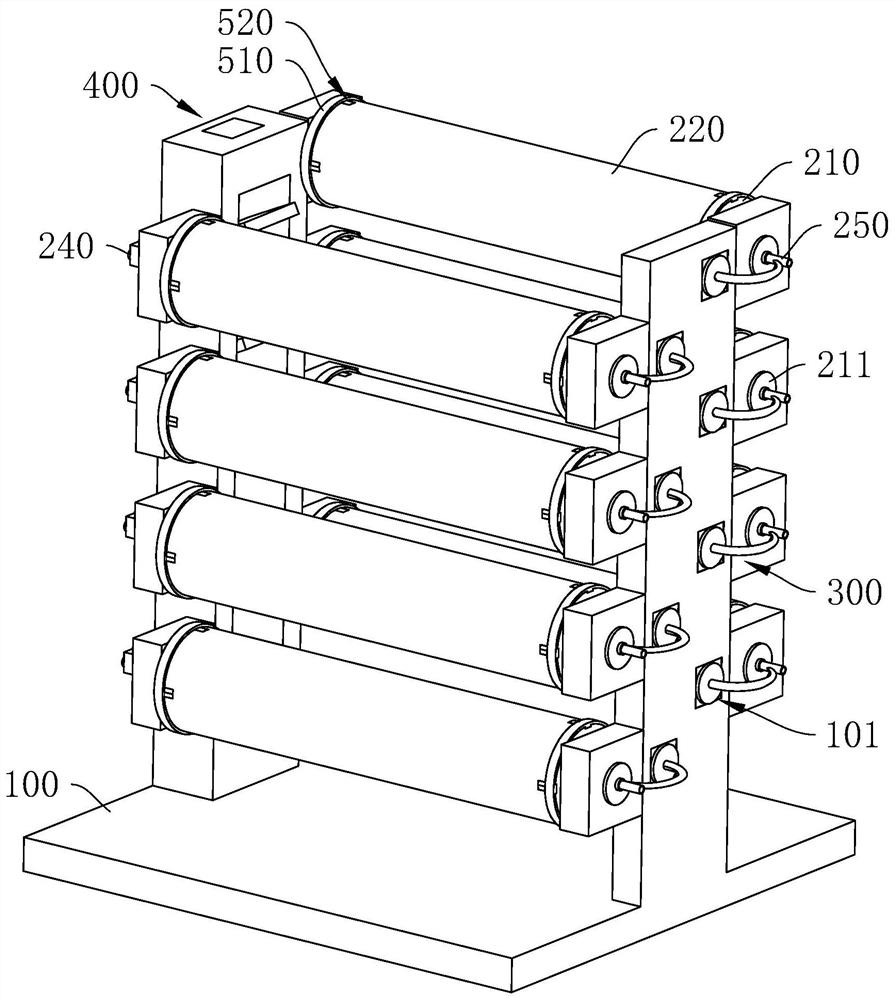

[0051] refer to figure 1 and figure 2 , a drying device, comprising a frame 100, two sets of drying cylinders 200 are arranged at horizontal intervals on the frame 100, each group of drying cylinders 200 includes four drying cylinders 200, and the four drying cylinders 200 in the same group are vertically spaced apart On the rack 100, the eight drying cylinders 200 are staggered.

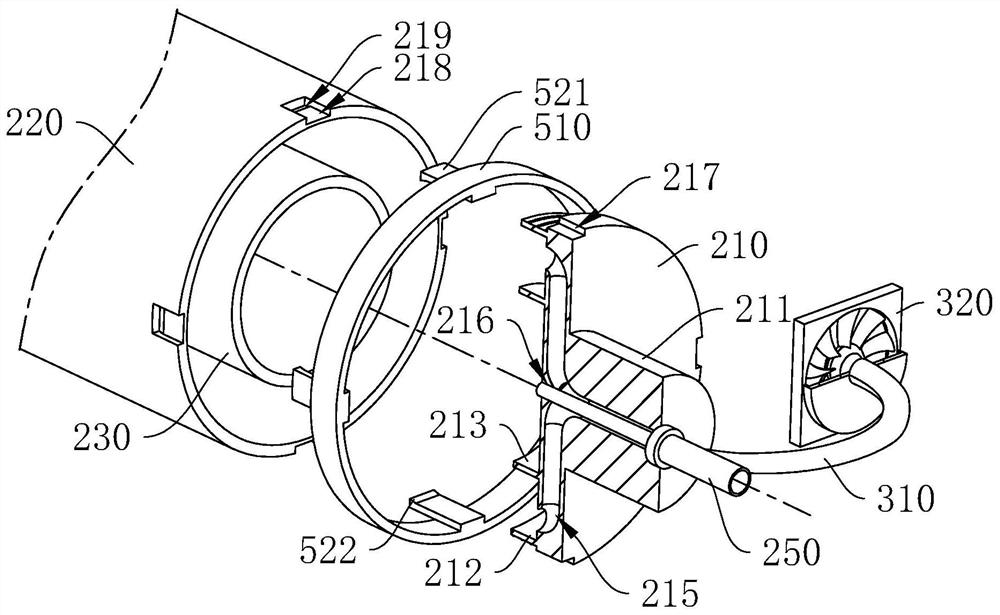

[0052] refer to figure 2 and image 3 The drying cylinder 200 includes two turntables 210, a first sleeve 220, a second sleeve 230, a water inlet pipe 240 and a water outlet pipe 250. One end of the turntable 210 is coaxially provided with a cylindrical rotating shaft 211, and the rotating shaft 211 is installed in a horizontal rotation. On the rack 100, the turntable 210 is located between the two rotating shafts 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com