Rotary flame type smokeless firewood gasification furnace

A gasifier and rotary airflow technology, applied in the field of biomass energy utilization, can solve the problem of inability to achieve a smokeless combustion state, and achieve the effects of reducing living energy costs, improving atmospheric environment, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

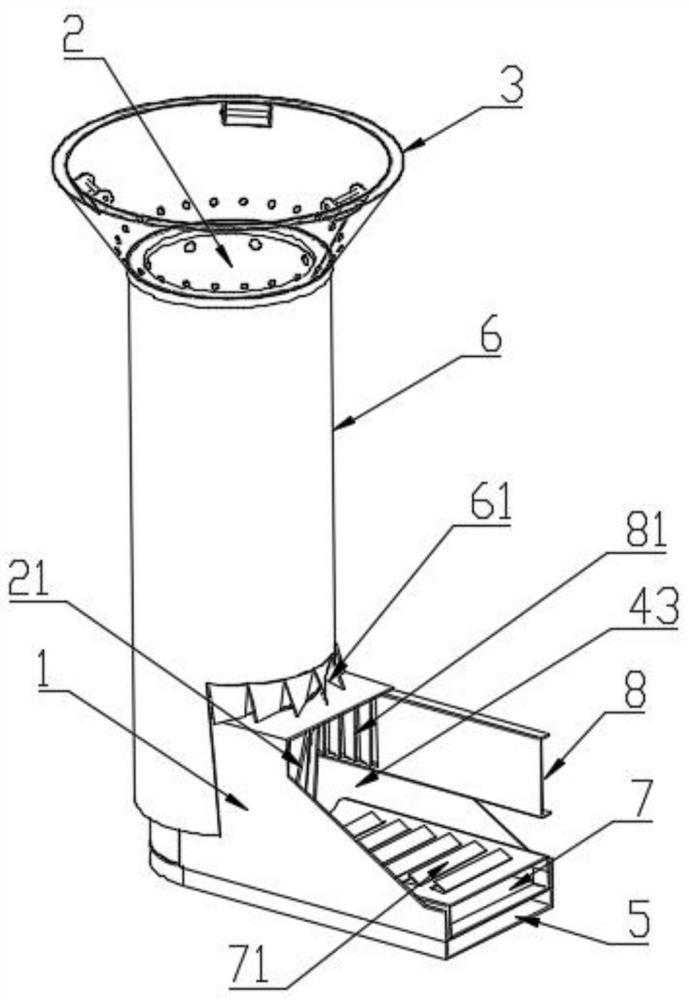

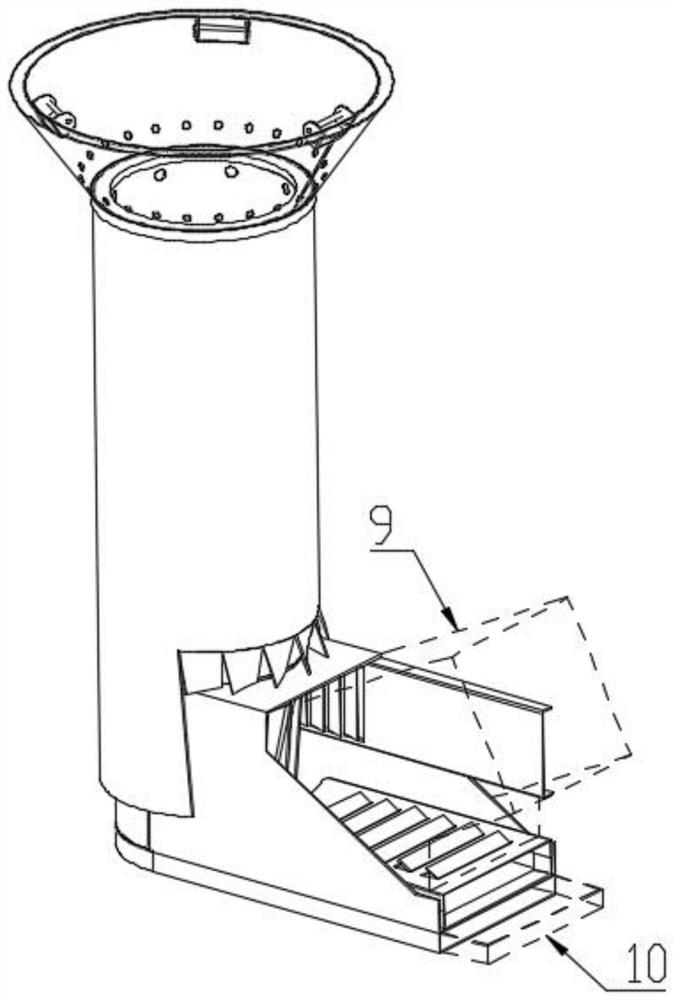

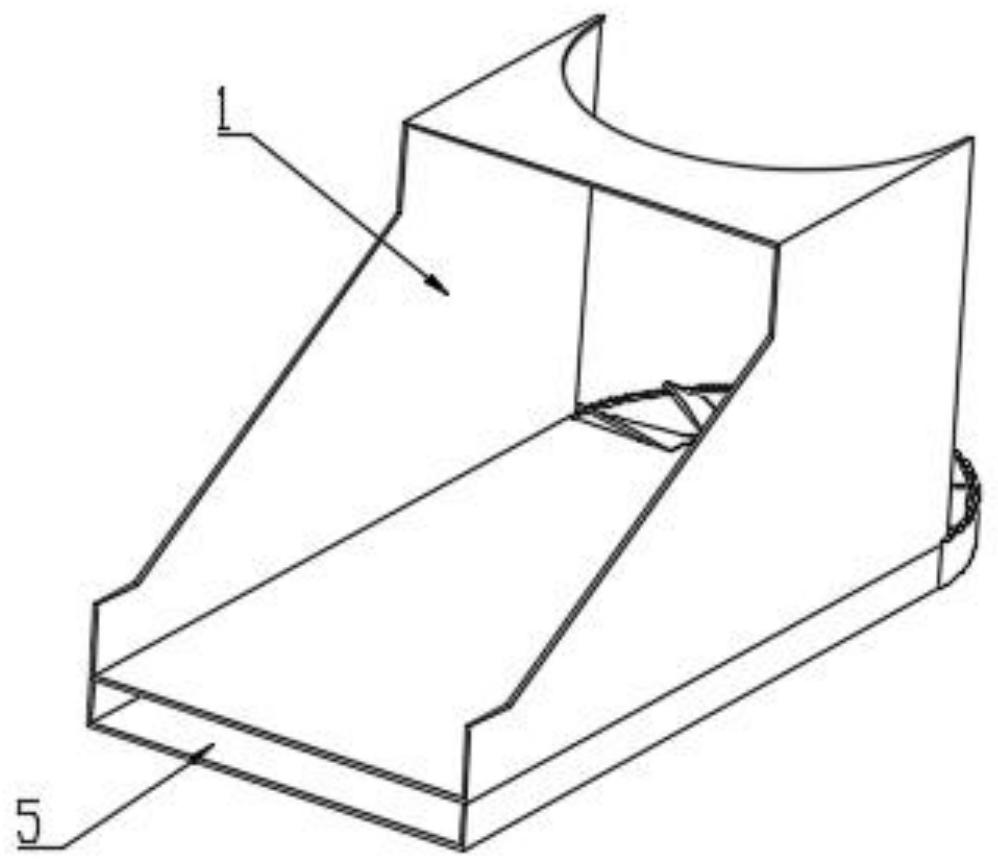

[0040] see Figure 1 to Figure 10 , in a specific embodiment, a rotary flame smokeless firewood gasification furnace, comprising a combustion cylinder 2 arranged above the gasification chamber 1;

[0041] The bottom surface of the combustion tube 2 is provided with a wind wheel plate 4 that can generate a rotating air flow, and the bottom air inlet channel 5 is communicated with the bottom of the wind wheel plate 4; wherein the wind wheel plate 4 is a fan blade structure, which is annular or fan-shaped; The air entering the channel 5 rises from the bottom surface of the combustion tube 2 into the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com