Composite seal-based spiral sheet sealing assembly

A sealing component and composite sealing technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of difficult assembly, high process requirements, and inconvenient disassembly and assembly, and achieve simple and reliable structure, strong safety, and easy maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

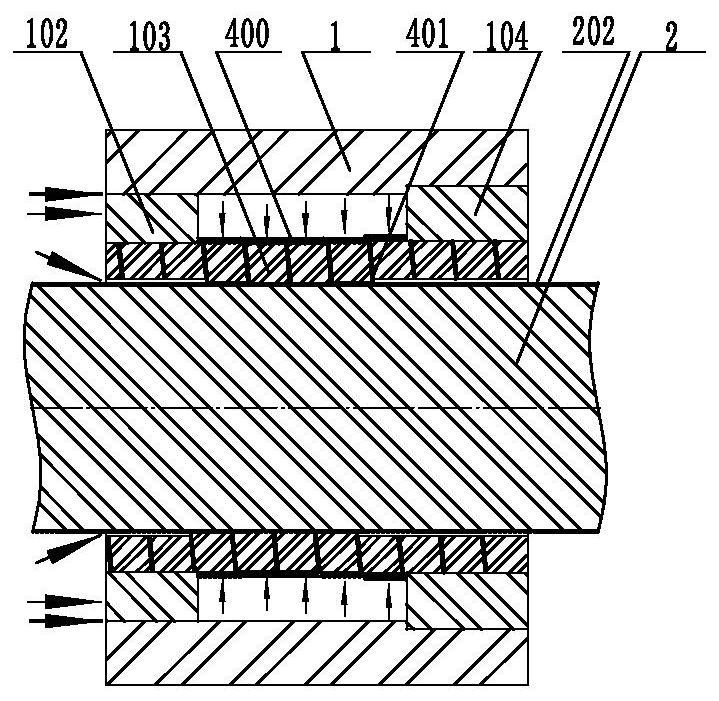

[0071] See attached figure 1 , a group of helical sheet sealing components wrapping the sealed part 2, from left to right are the toggle ring 102, the spiral sealing sheet A103 and the fixed ring 104, the toggling ring 102 and the fixed ring 104 wrap the two ends of the spiral sealing sheet A103 and connect them The flexible film 400 wraps the spiral sealing sheet A103, the axial spiral end surface of the spiral sealing sheet A103 has a sealing coating 401, and the outer ring surface of the sealed part 2 has a wear-resistant coating 202.

Embodiment 2

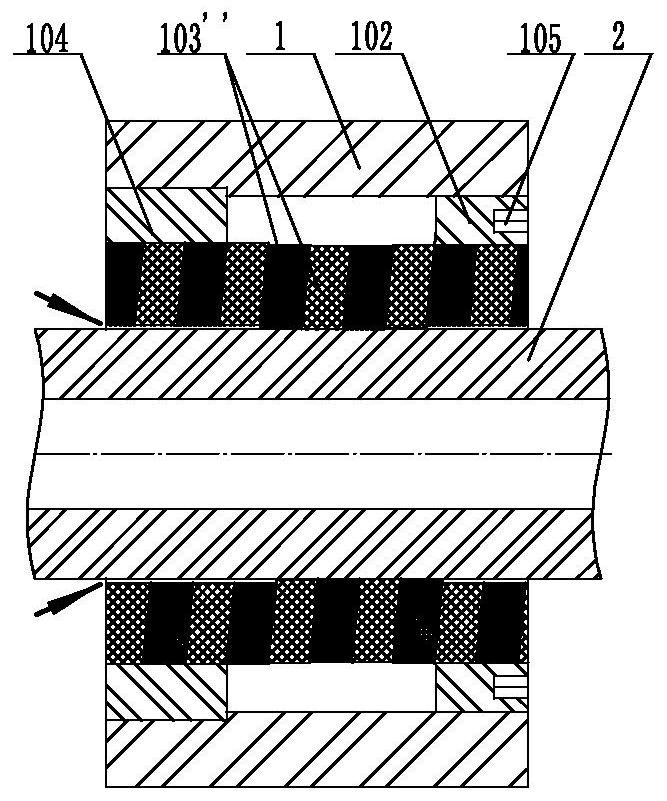

[0073] See attached figure 2 , there is a group of helical sheet sealing components in the sealing cabin 1 to wrap the tubular sealed part 2, the helical sheet sealing components are the fixed ring 104, the screw sealing sheet C103″ and the toggle ring 102 from left to right, the fixed ring 104 and the toggle ring 102 wraps the two ends of the spiral sealing sheet C103" and connects them; the outer ring surface of the toggle ring 102 is adjustable and tight fit with the inner annular surface of the airtight cabin 1, and the axial outer end surface of the toggle ring 102 has an adjustable radial rotation angle Process hole 105 .

Embodiment 3

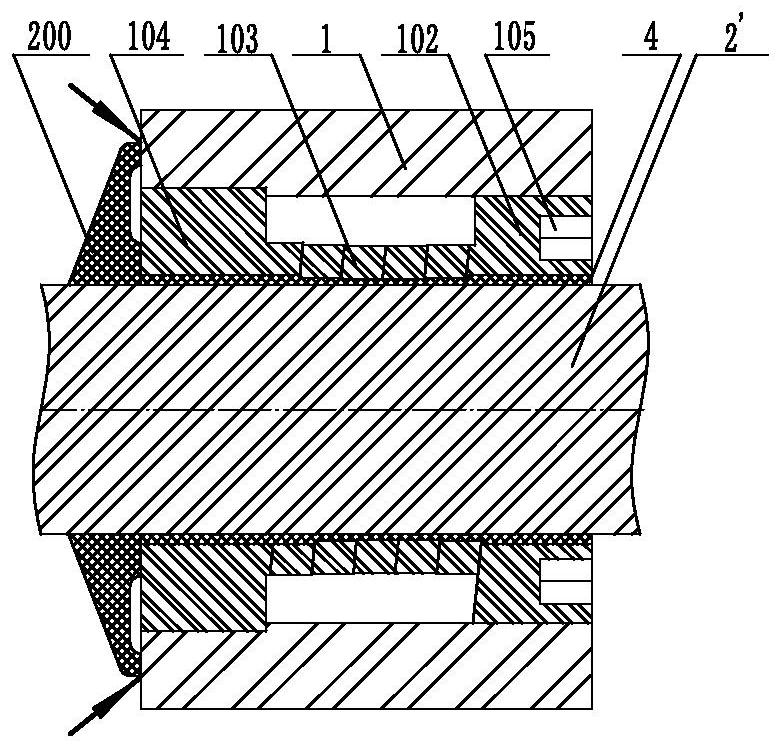

[0075] See attached image 3 , used for low-speed rotation seals such as valve stem seals, a set of spiral leaf seal components wraps the rotating shaft 2' or the spiral motion shaft, and from left to right are the leather cup 200, the fixed ring 104, the spiral seal A103 and the toggle ring 102 , the fixed ring 104 and the toggle ring 102 are integrated with the spiral sealing sheet A103, the spiral sheet sealing assembly wraps a flexible sealing sleeve 4, the outer ring surface of the toggle ring 102 is adjustable and tight fit with the inner ring surface of the sealing cabin 1, The axial outer end surface of the toggle ring 102 has a process hole 105 ; wherein, the inner end surface of the cup 200 is in contact with the corresponding outer end surface of the sealing chamber 1 and the fixed ring 104 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com