Universal planetary gear reducer for outer rotor type motor

A technology of gear reducer and planetary gear, which is applied in the direction of gear transmission, belt/chain/gear, electrical components, etc., can solve the problem of no supporting reducer, etc., and achieve the effect of enhancing torque and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

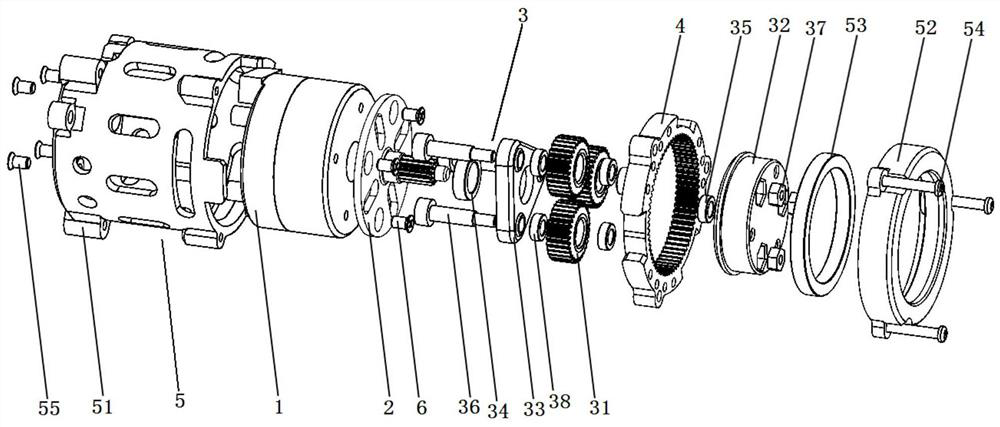

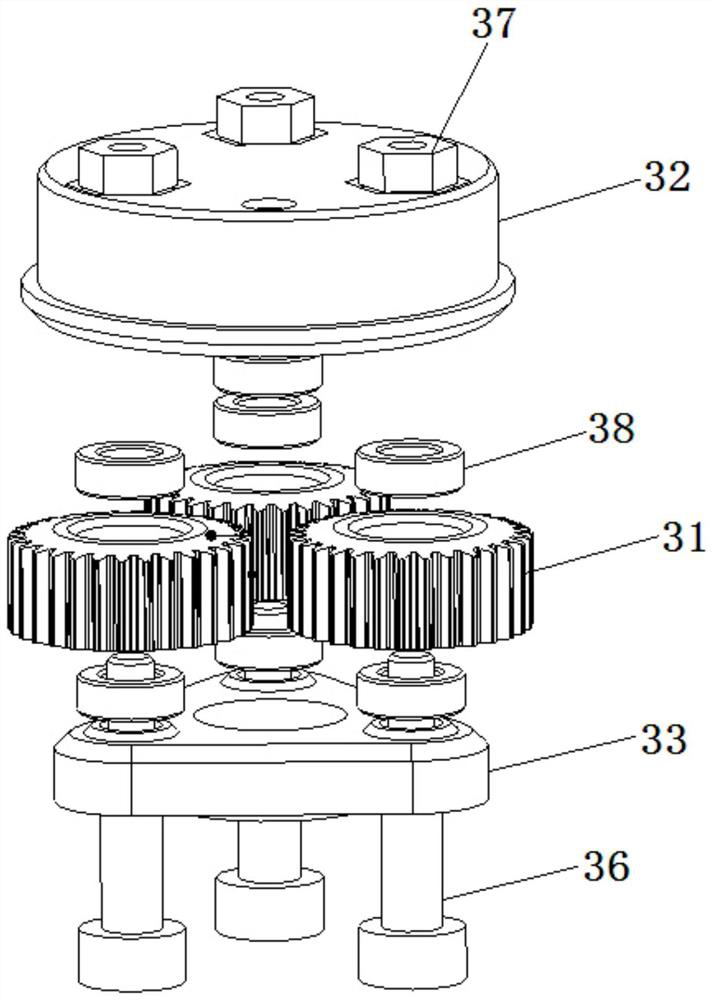

[0031] refer to figure 1 , 9 , the universal planetary gear reducer of the outer rotor type motor in this embodiment includes a motor 1, a flange type sun gear 2, a planetary gear carrier assembly 3, an inner ring gear 4, and a support frame assembly 5. The flange type The sun gear 2 includes a flange 21 and a gear shaft 22 fixed at the center of the flange 21. The flange 21 of the flange type sun gear 2 is fixed on the rotation center of the motor 1. The flange type The gear shaft 22 of the sun gear 2 is connected with the planetary gear 31 and the planetary carrier of the planetary gear carrier assembly 3, and the planetary gear 31 of the planetary wheel carrier assembly 3 meshes with the ring gear 4, and the planetary carrier assembly 3 The planet carrier of 3 is used to output the power of the motor 1, and the support frame assembly 5 is set on the outside of the motor 1, the flanged sun gear 2, and the planetary gear carrier assembly 3, and is fixed with the motor 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com