Environment-friendly shaving board pressing equipment

A particleboard and equipment technology, applied in the field of environmental protection particleboard pressing equipment, can solve the problems of high humidity of particleboard, affecting subsequent use, drying, etc., and achieve the effect of avoiding excessive length and high pressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of environmental protection particleboard pressing equipment, such as Figure 1-Figure 4 As shown, it includes a base 1, a support frame 2, an n-shaped support plate 3, a pressing mechanism 4, and a drying mechanism 5. The support frame 2 is fixed symmetrically on the right side of the top of the base 1, and the right side of the top of the base 1 is fixed at intervals. There is an n-shaped support plate 3, the n-shaped support plate 3 is located on the left side of the support frame 2, a pressing mechanism 4 is arranged between the base 1 and the support frame 2 and the n-shaped support plate 3, and a pressing mechanism 4 is arranged between the pressing mechanism 4 and the base 1. There are drying mechanism 5.

[0028] The pressing mechanism 4 includes a servo motor 41, a drive shaft 42, a pressing roller 43, a feeding belt 44, a timing belt 45, a transmission gear assembly 46, a transmission belt assembly 47, a grooved belt 48 and a first transmission shaft 49...

Embodiment 2

[0032] On the basis of Example 1, such as figure 1 , image 3 , Figure 4 , Image 6 with Figure 7 As shown, a cutting mechanism 6 is also included. The cutting mechanism 6 includes a mounting frame 61, a sliding block seat 62, a lifting column 63, a fixed plate 64, an inverted saw chain 65, a high-speed response motor 66 and a guide column 67. The base 1 The right side of the top is fixedly connected with a mounting frame 61 symmetrically front and back, and a guide post 67 is fixedly connected between the lower parts of the left and right sides in the mounting frame 61. The sliding type on the guide post 67 is provided with a sliding block seat 62, and the sliding block seat 62 is installed. The lifting column 63 is provided in the formula, and the top of the lifting column 63 on the front and rear sides is fixedly connected with a fixed plate 64, and the right side of the top of the fixed plate 64 is rotated to be provided with an inverted tooth saw chain 65. A high-sp...

Embodiment 3

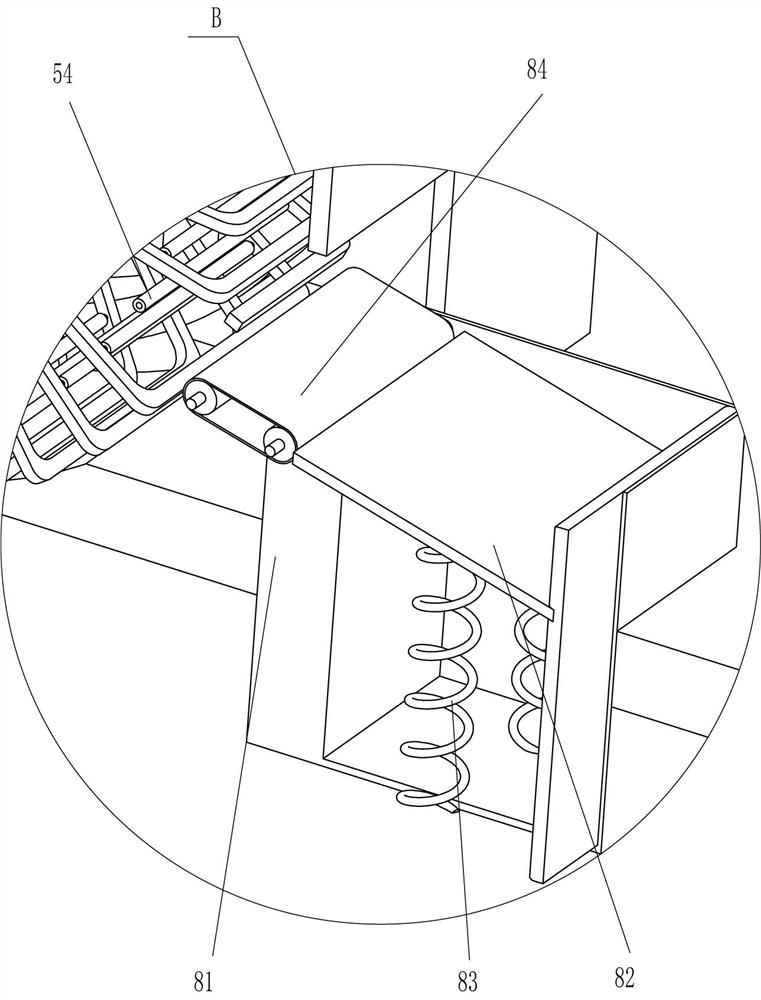

[0037] On the basis of embodiment 1 and embodiment 2, such as figure 1 , image 3 , Figure 5 with Image 6 Shown, also includes blanking mechanism 8, and blanking mechanism 8 includes blanking box 81, sponge pad 82, blanking spring 83 and guide belt 84, and heat insulation box 55 right middle lower part rotation type is provided with guide belt 84 In the middle of the left part of the base 1, a blanking box 81 is affixed, and a blanking spring 83 is affixed symmetrically front and back in the bottom of the blanking box 81, and a sponge pad 82 is affixed between the two blanking springs 83 tail ends.

[0038] Also includes cleaning mechanism 9, and cleaning mechanism 9 includes material receiving box 91, fixed shaft 92 and cleaning wheel 93, and base 1 top is fixedly connected with material receiving box 91 in the middle of the top, and rotates between the front and rear sides left parts in material receiving box 91 Formula is provided with fixed shaft 92, and fixed shaft 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com