Robot movement mechanism

A motion mechanism and robot technology, applied in the field of robots, can solve the problems of large external size, large size, and large space occupation, and achieve the effect of reducing overall size and manufacturing cost, improving stability and reliability, and reducing space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the present invention will be further described below with reference to the accompanying drawings and examples. Obviously, the described embodiments are merely embodiments of the invention, not all of the embodiments. In the case of an unable conflict, the features and embodiments in the present invention can be combined with each other.

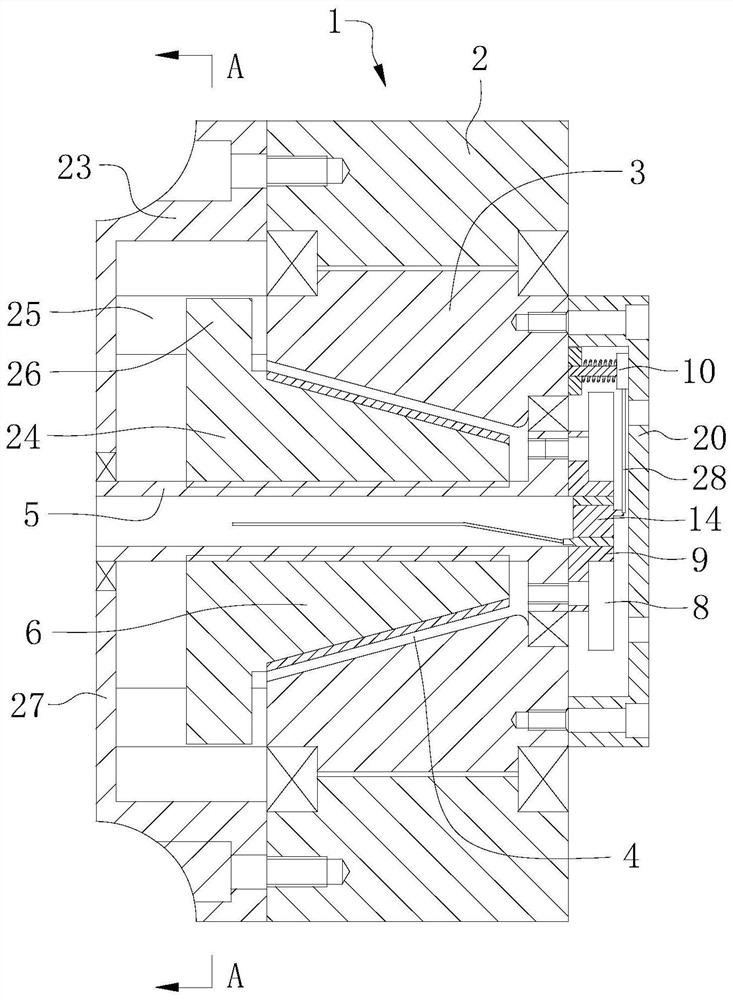

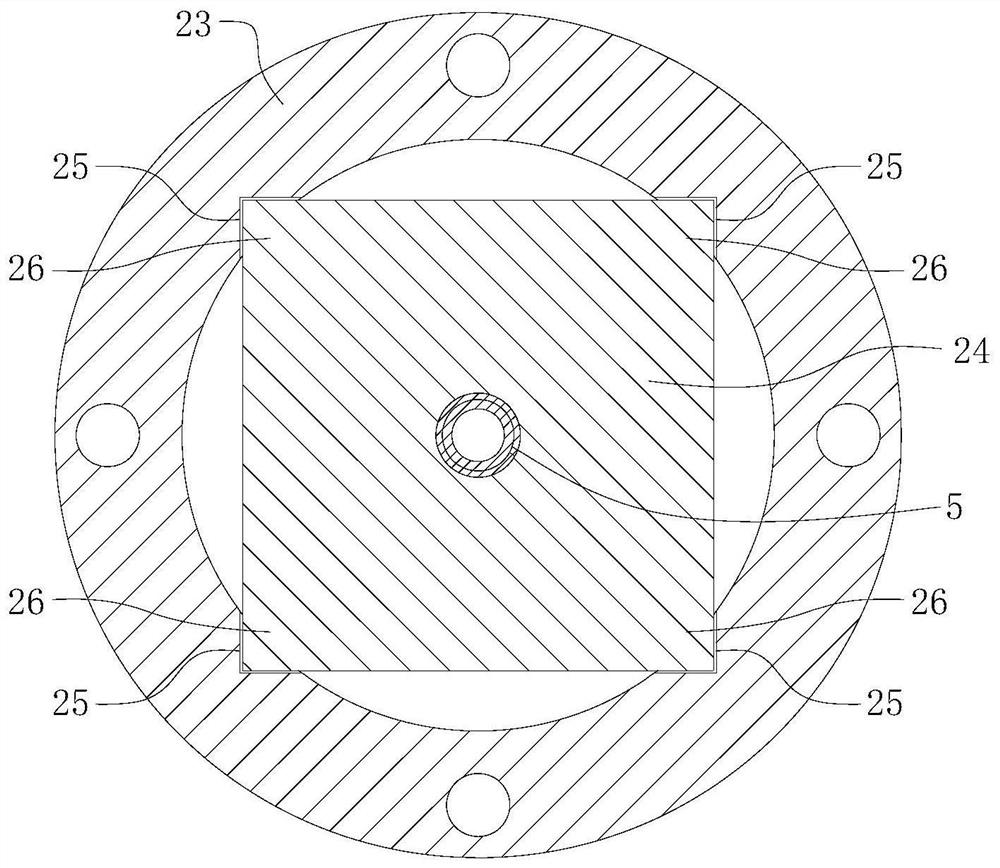

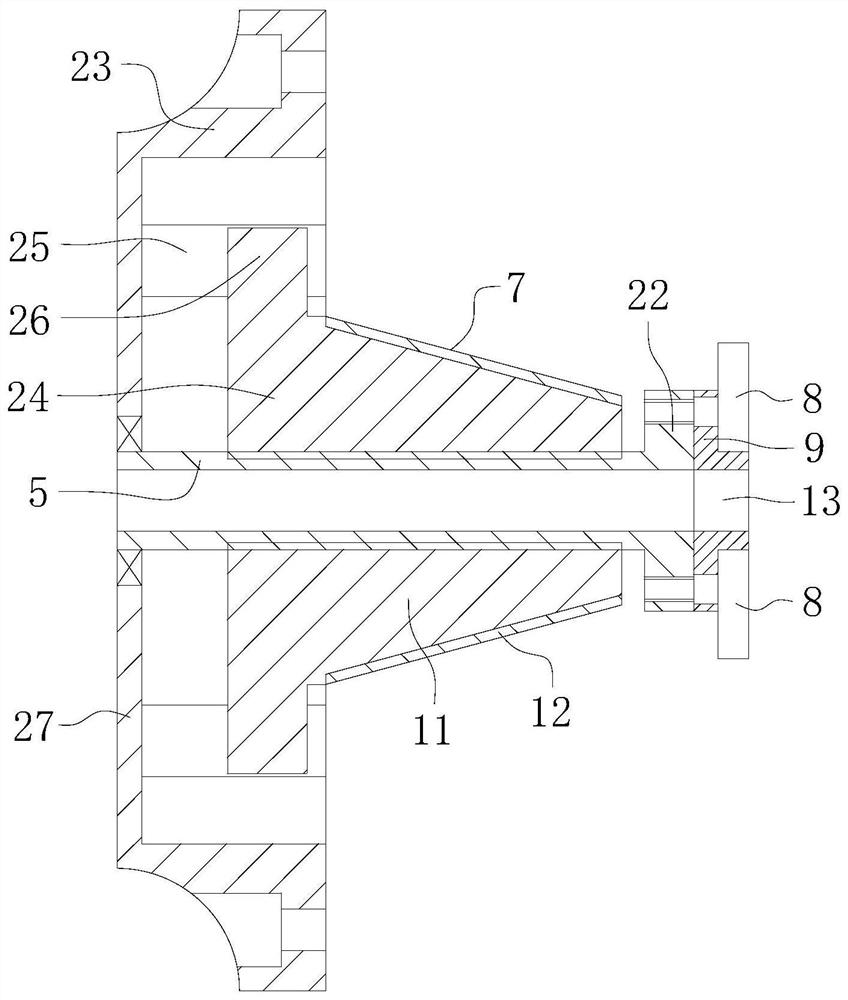

[0030] figure 1 It is a schematic structural diagram of a robot motion mechanism according to an embodiment of the present invention; figure 2 Yes figure 1 A cross-sectional view of the A-A.

[0031] See figure 1 , figure 2 , The robot moving mechanism provided by the embodiment of the present invention, includes a motor 1; the motor 1 includes a motor stator 2 and a motor rotor 3; the center of the motor rotor 3 has two ends opening, and a circular stage brake 4; The brake cavity 4 has a brake shaft 5 provided with the motor rotor 3, and the front end of the brake shaft 5 rotates thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com